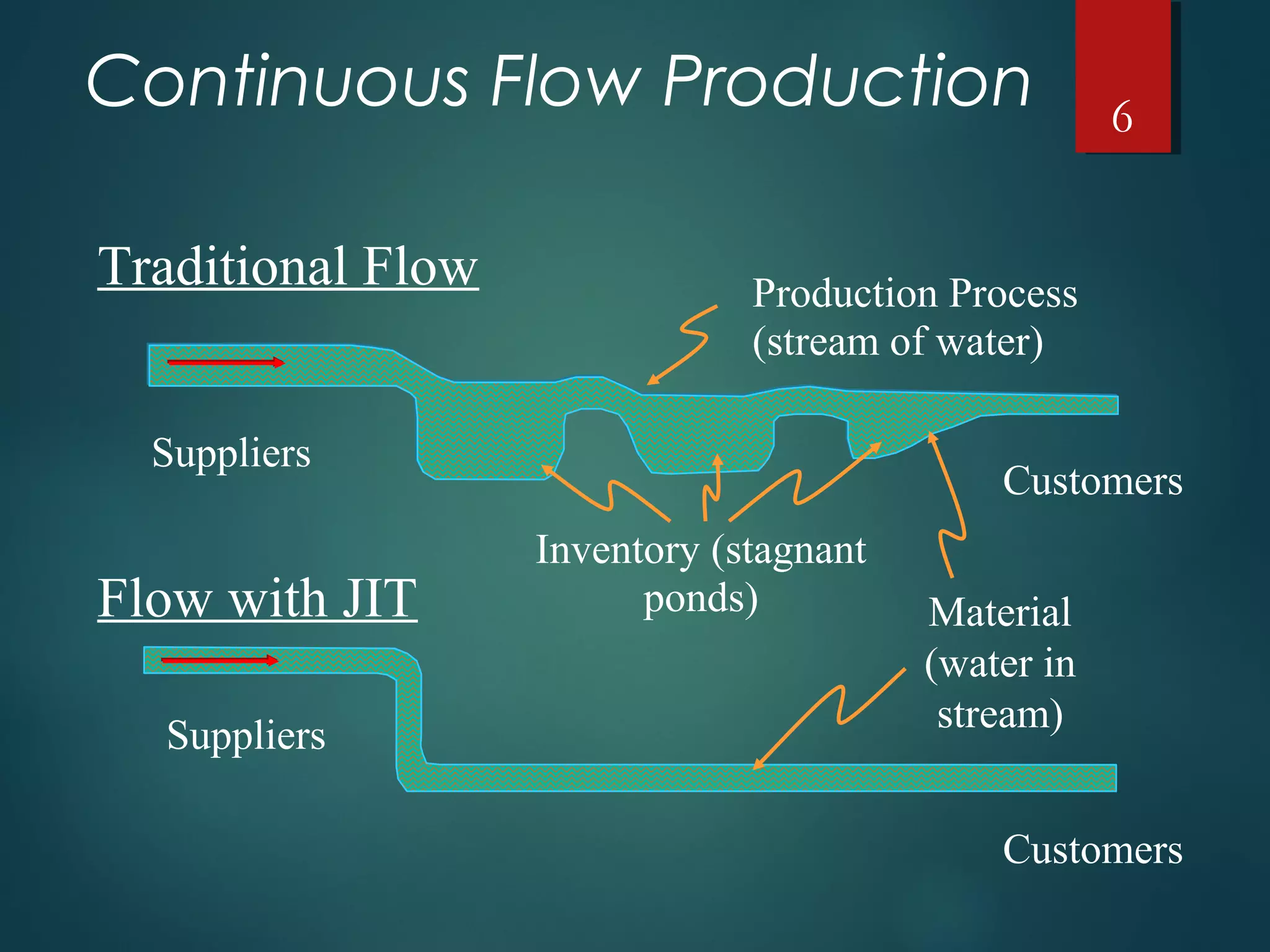

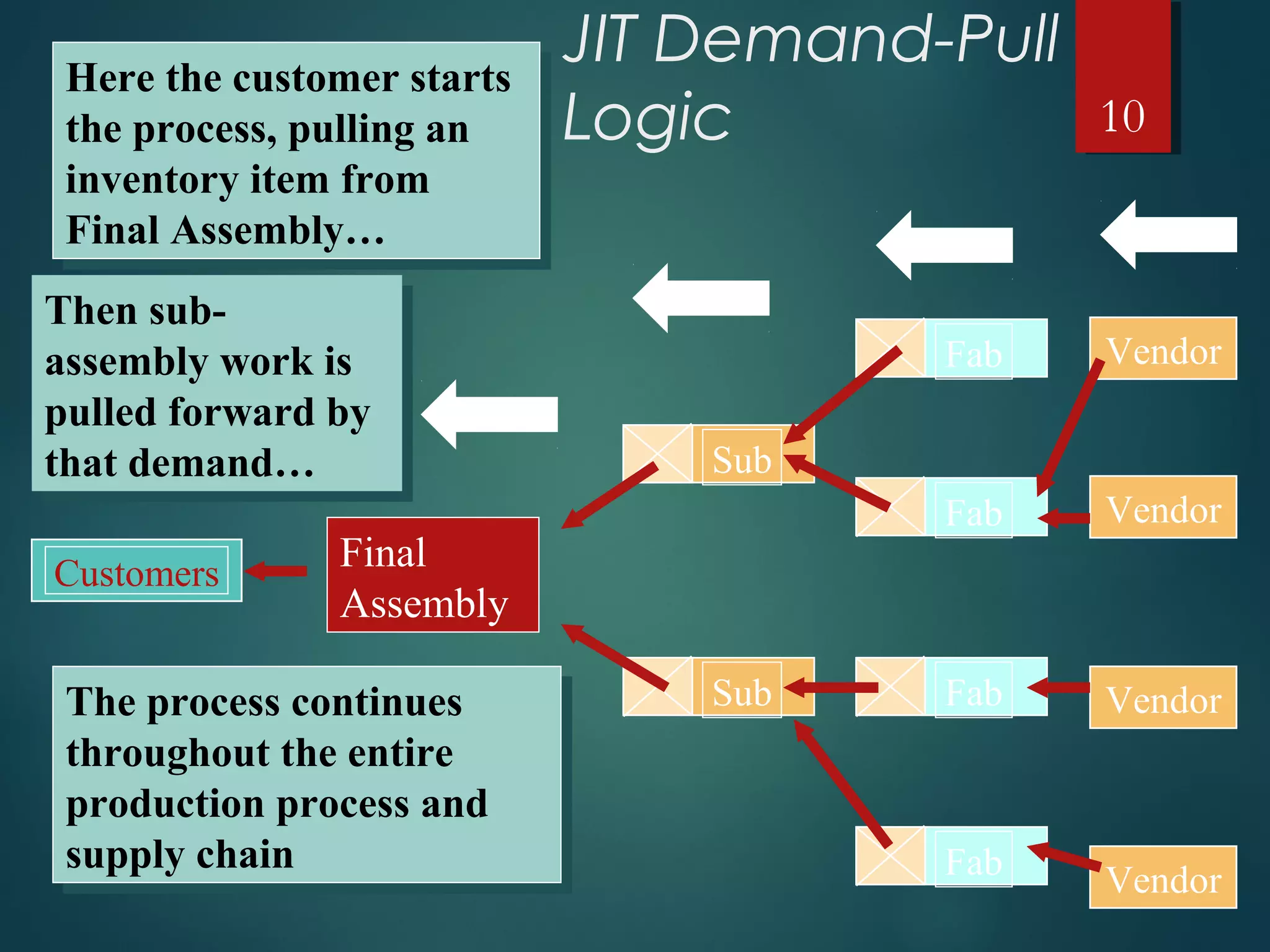

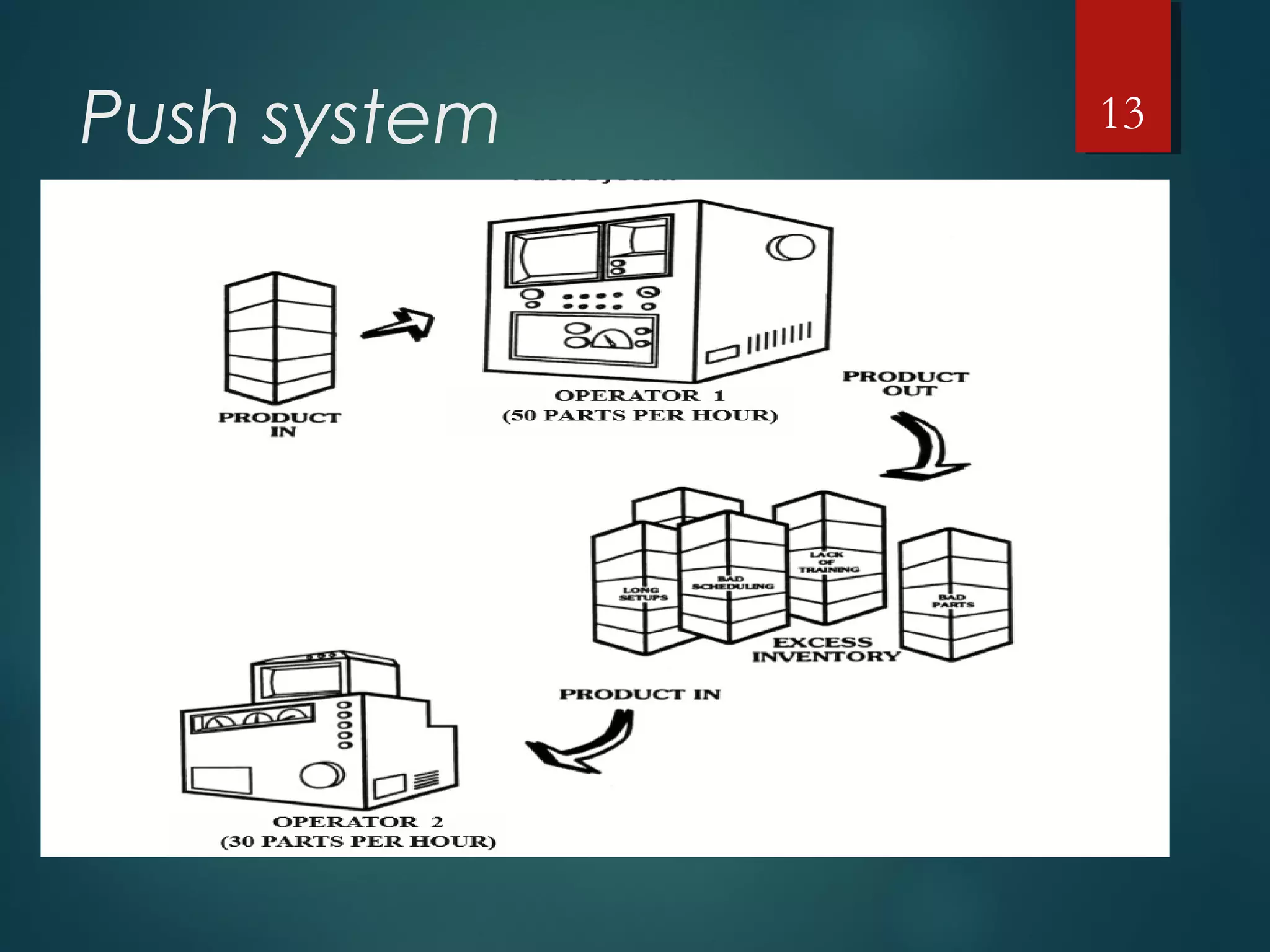

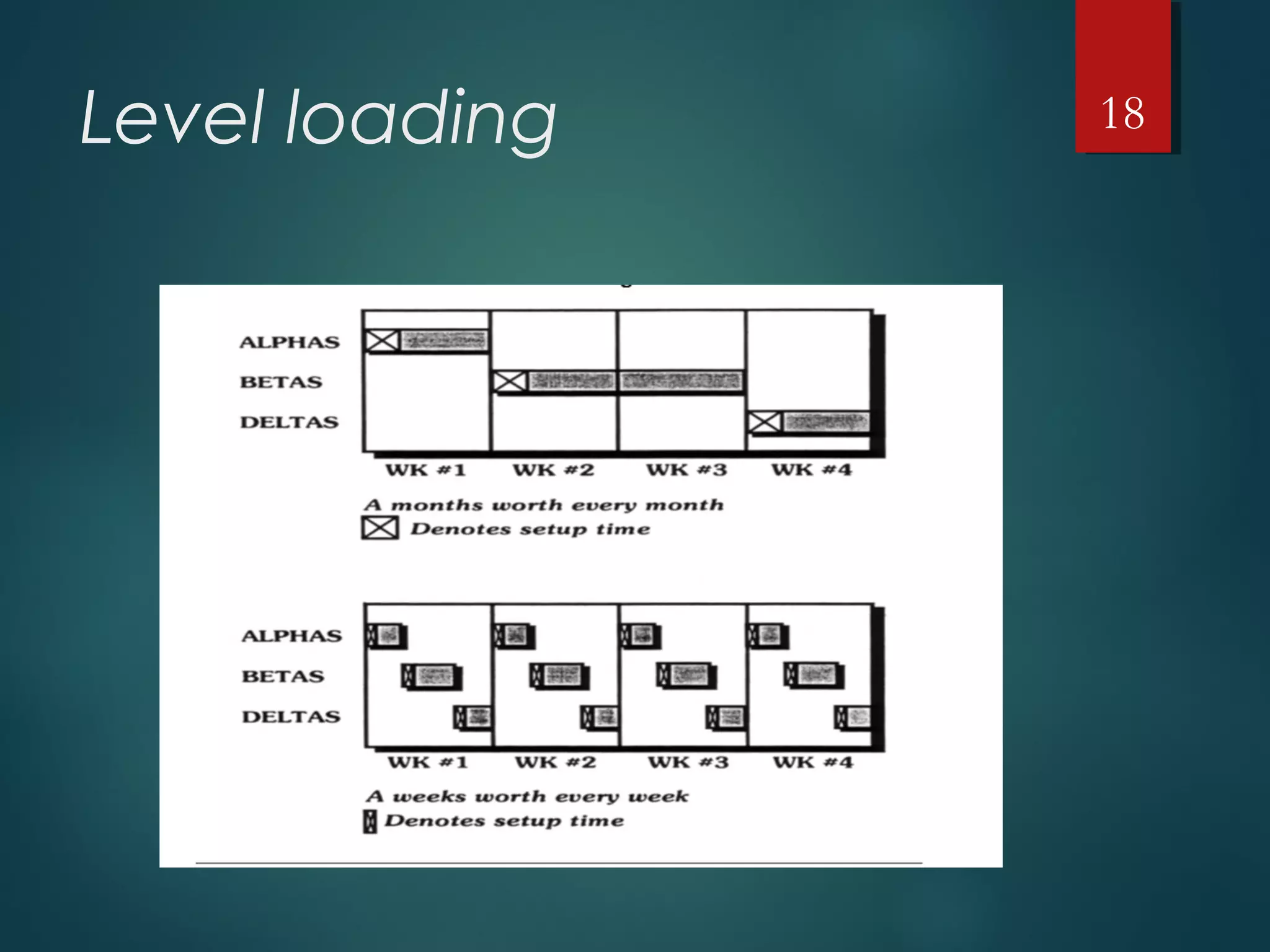

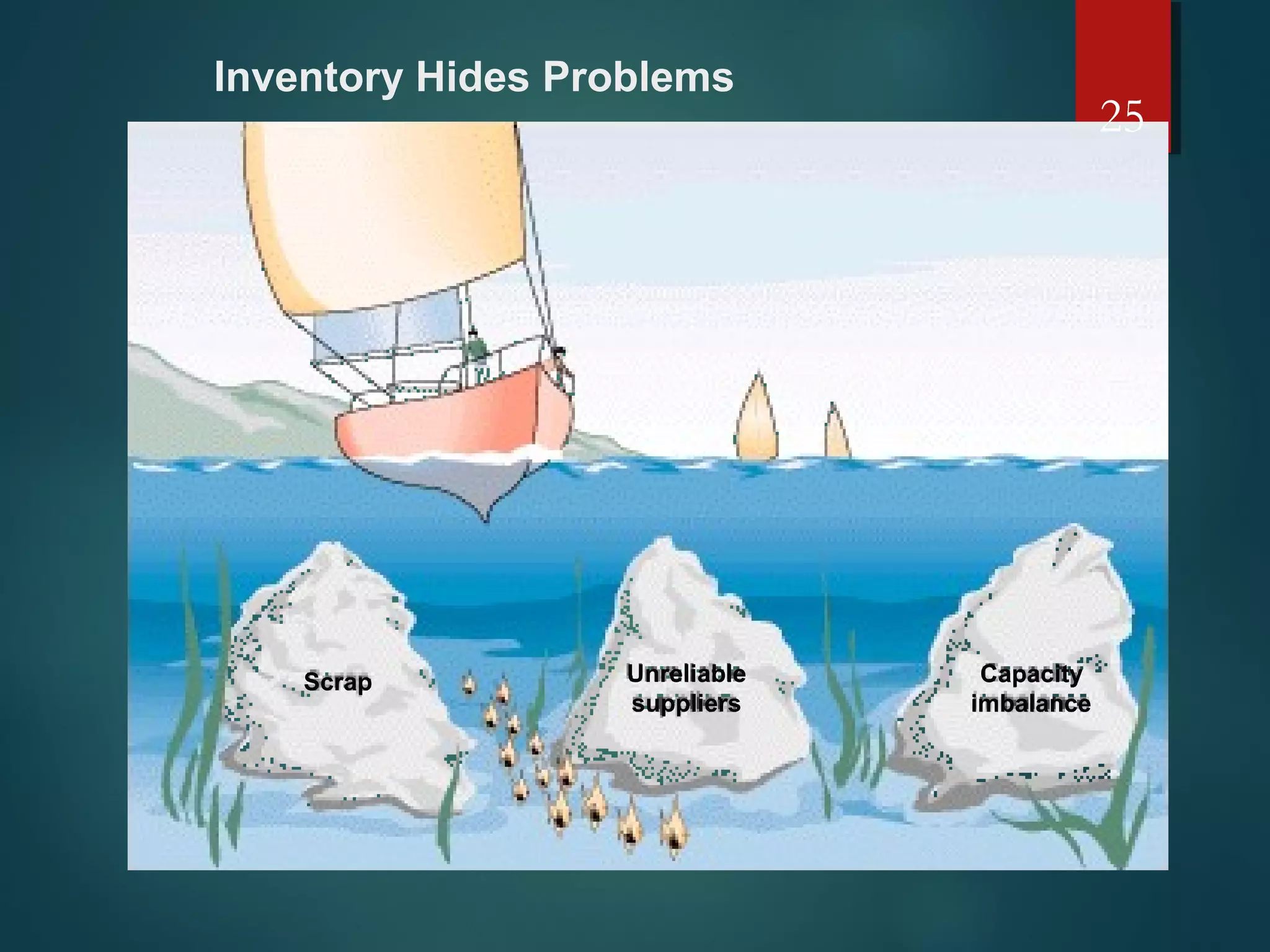

This document provides an overview of Just-In-Time (JIT) manufacturing. It defines JIT as producing the minimum amount of units at the latest possible time to eliminate inventory. The document then discusses key aspects of JIT like pull systems using kanban cards, continuous flow production, uniform workloads, quality control through statistical process control and preventative maintenance. It compares JIT to traditional push systems and highlights benefits like cost savings, revenue increases and workforce improvements from JIT. Potential barriers to implementing JIT in India are also outlined such as management resistance, employee resistance to change, and lack of immediate financial returns.