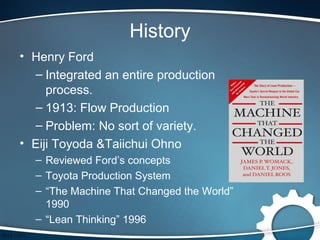

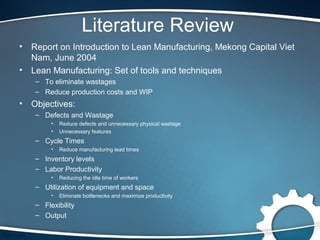

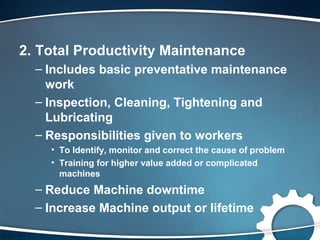

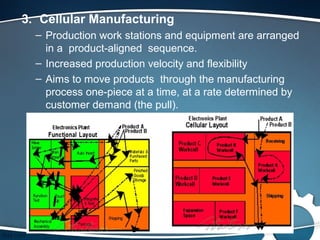

Lean manufacturing aims to eliminate waste in production processes through continuous improvement efforts. It focuses on minimizing inventory levels and non-value adding activities to reduce costs and lead times. Toyota pioneered this approach after World War 2 to rebuild efficiently without large economies of scale. Implementing lean principles like just-in-time production and cellular manufacturing allowed Toyota to dramatically reduce production cycle times and outcompete major automakers. A chemical company also successfully applied lean tools to halve inventory levels and cut order fulfillment times from 20 to 5 minutes. Lean techniques organize work areas, maintain equipment, and pull work through production cells to optimize flow.

![What is Lean Manufacturing?

• “Lean Manufacturing, also called Lean Production, is a

set of tools and methodologies that aims for the

continuous elimination of all waste in the production

process. The main benefits of this are lower production

costs, increased output and shorter production lead

times” [1]

• “A systematic approach to identifying and eliminating

waste and NVA (non-value added activity) through

continuous improvement and flowing the product at the

pull of the customer in pursuit of perfection”. [2]](https://image.slidesharecdn.com/leanmanufacturing-130319034138-phpapp02/85/Lean-manufacturing-2-320.jpg)