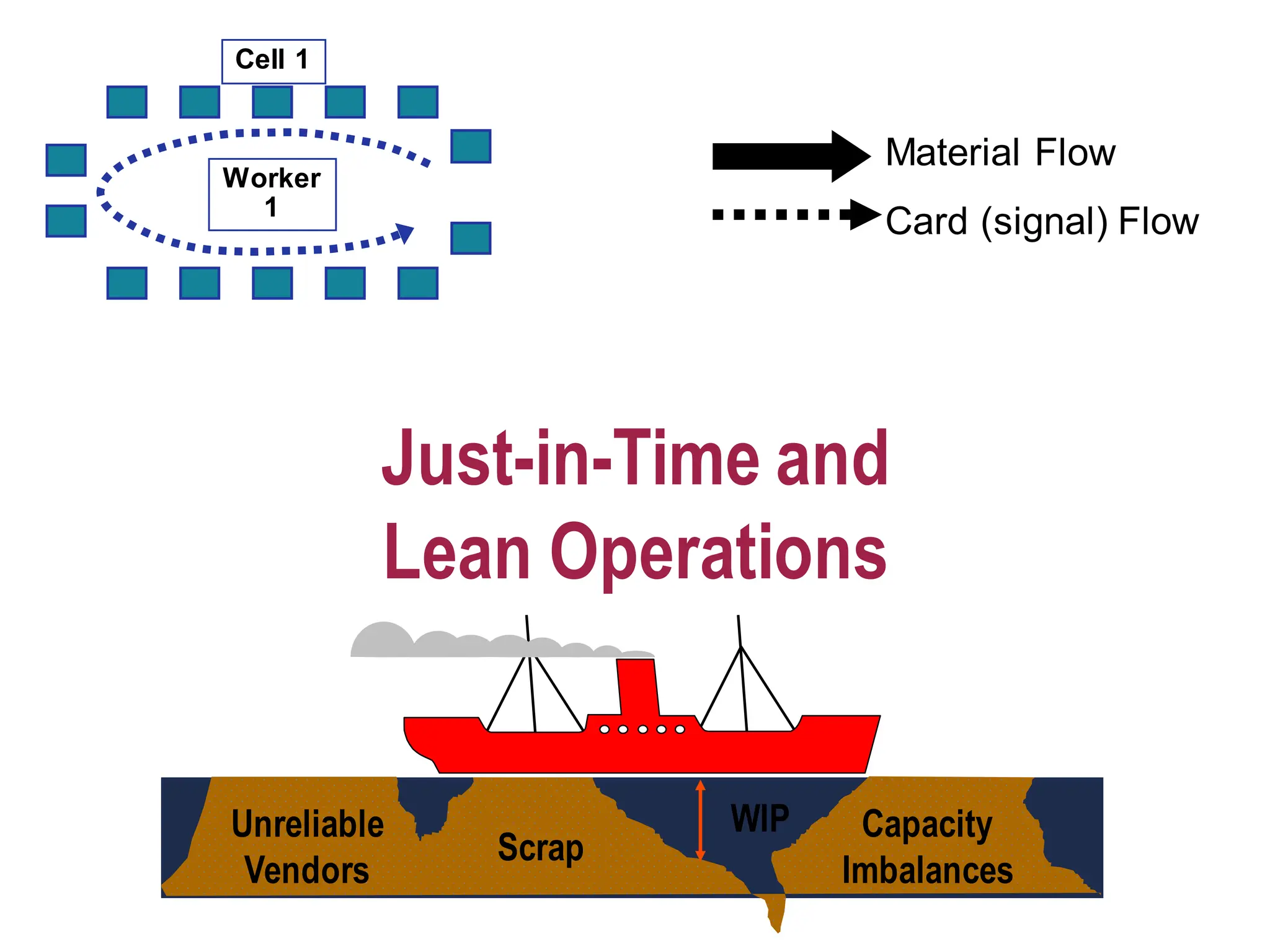

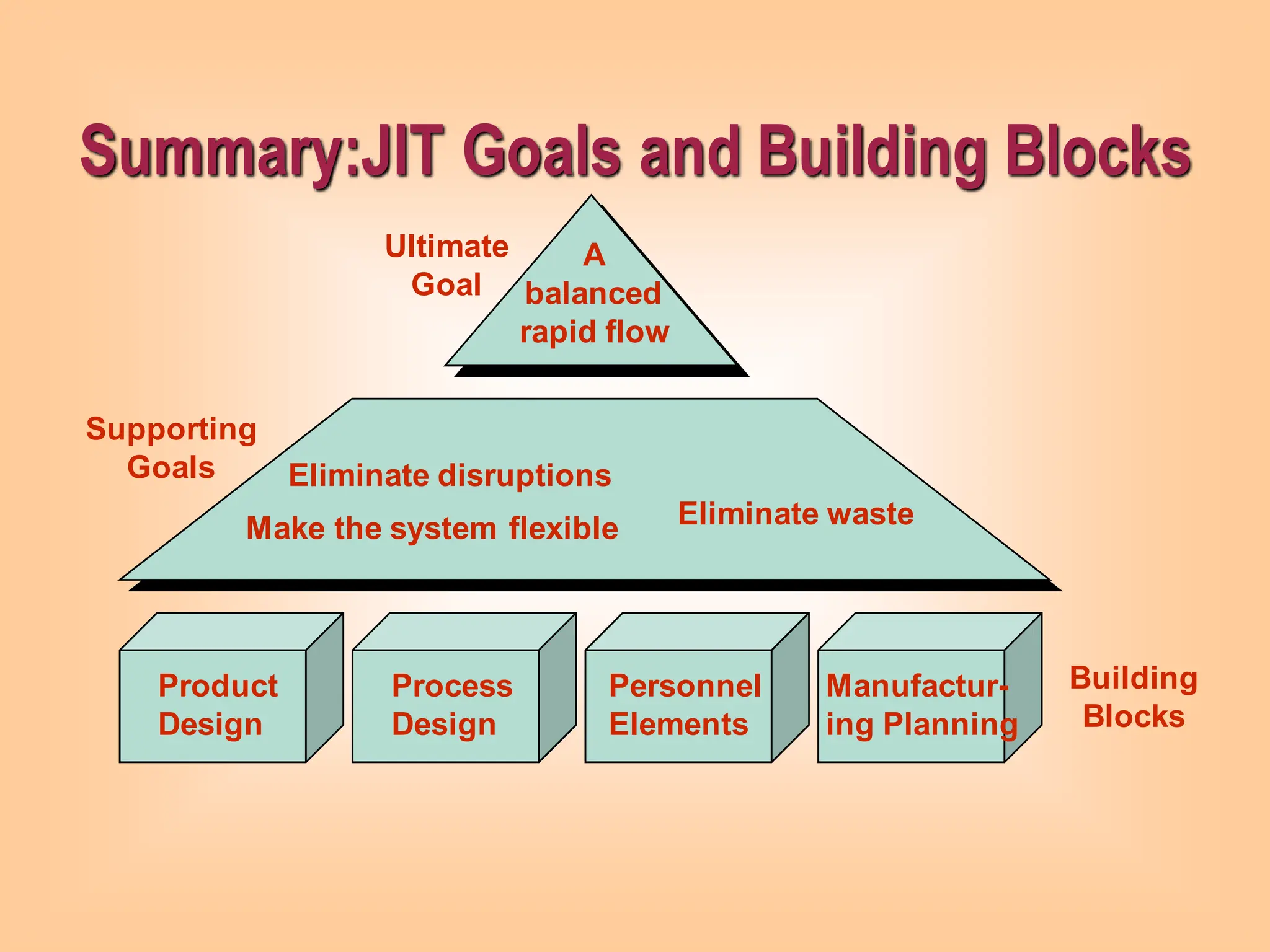

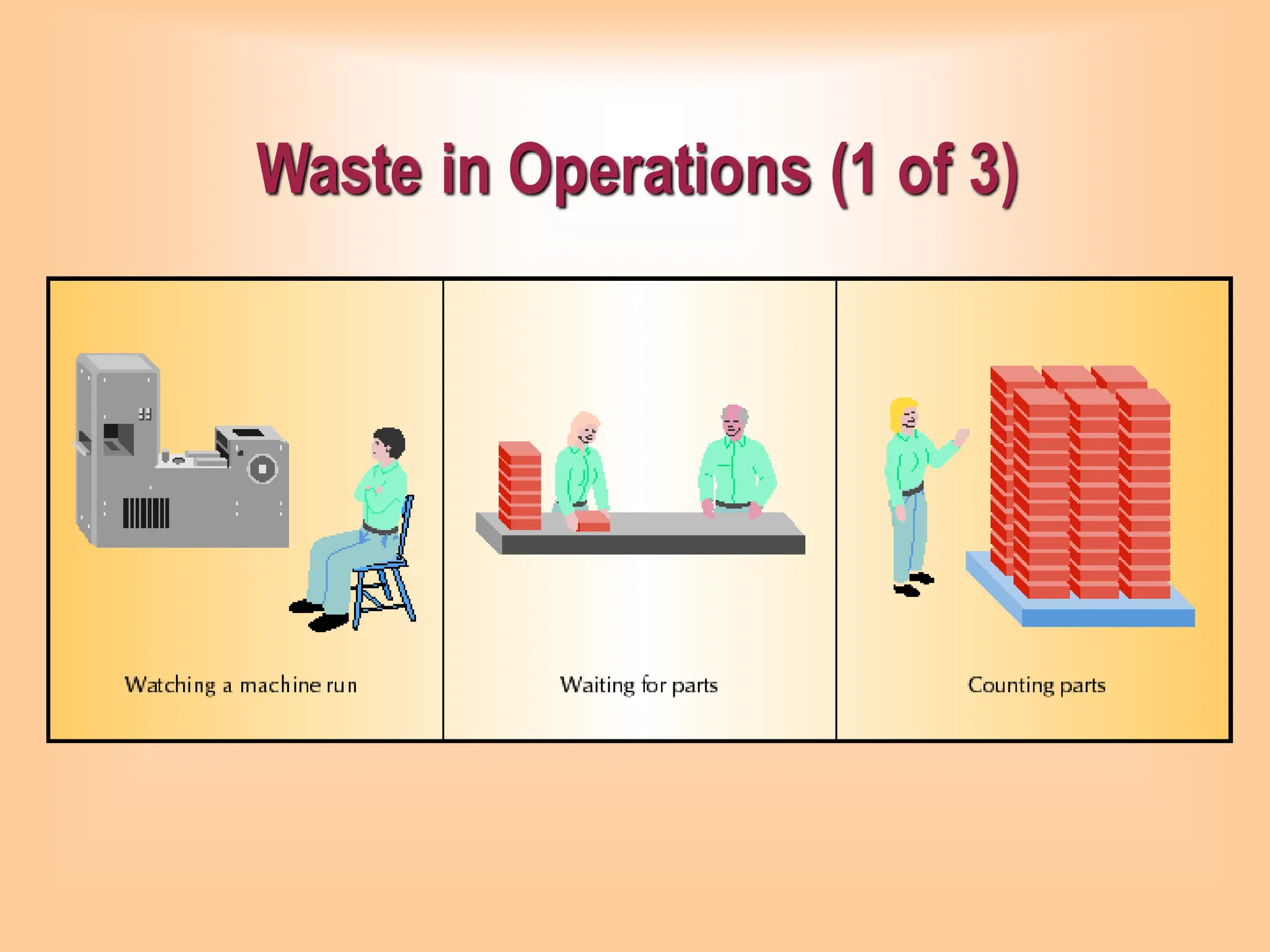

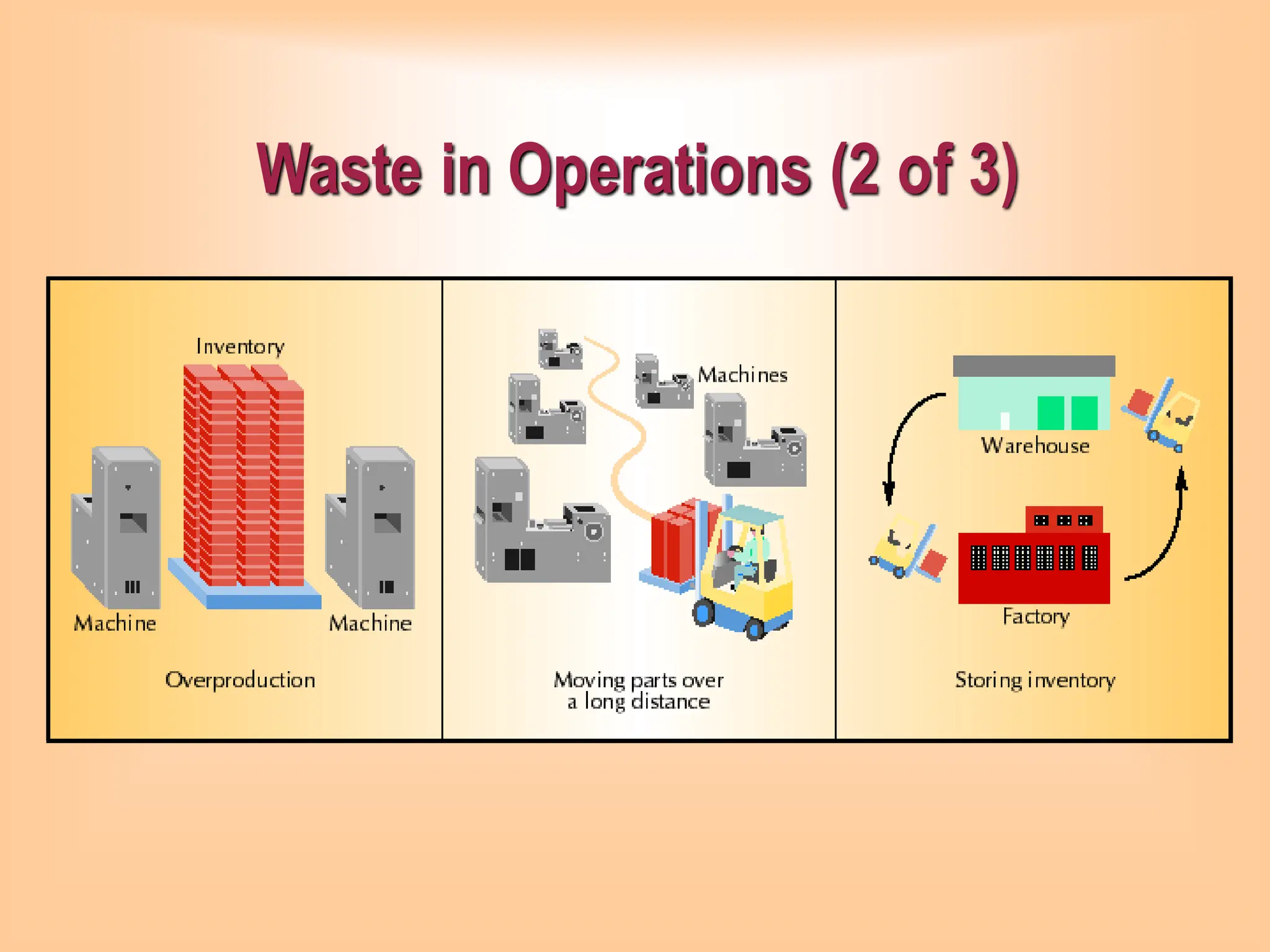

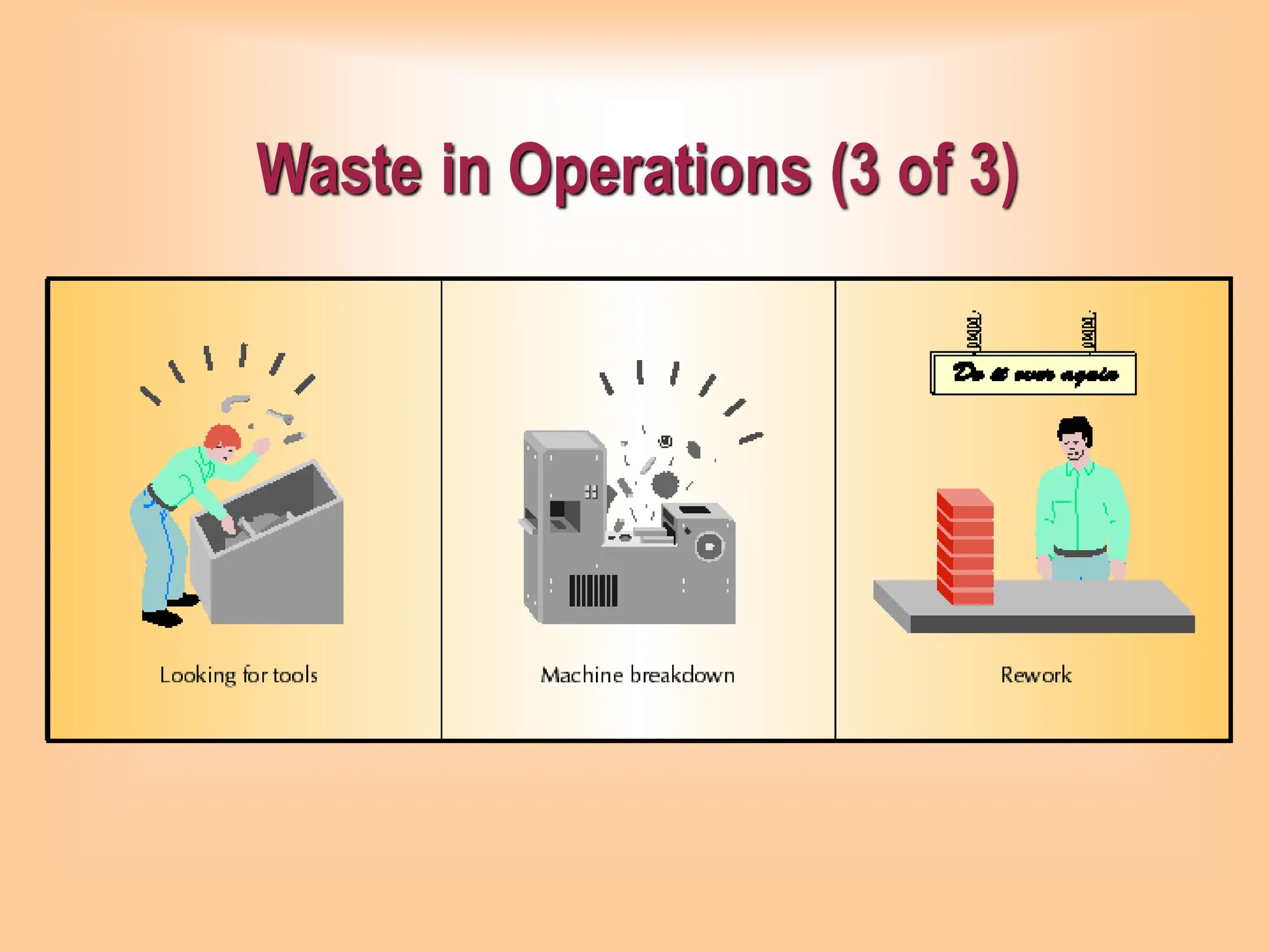

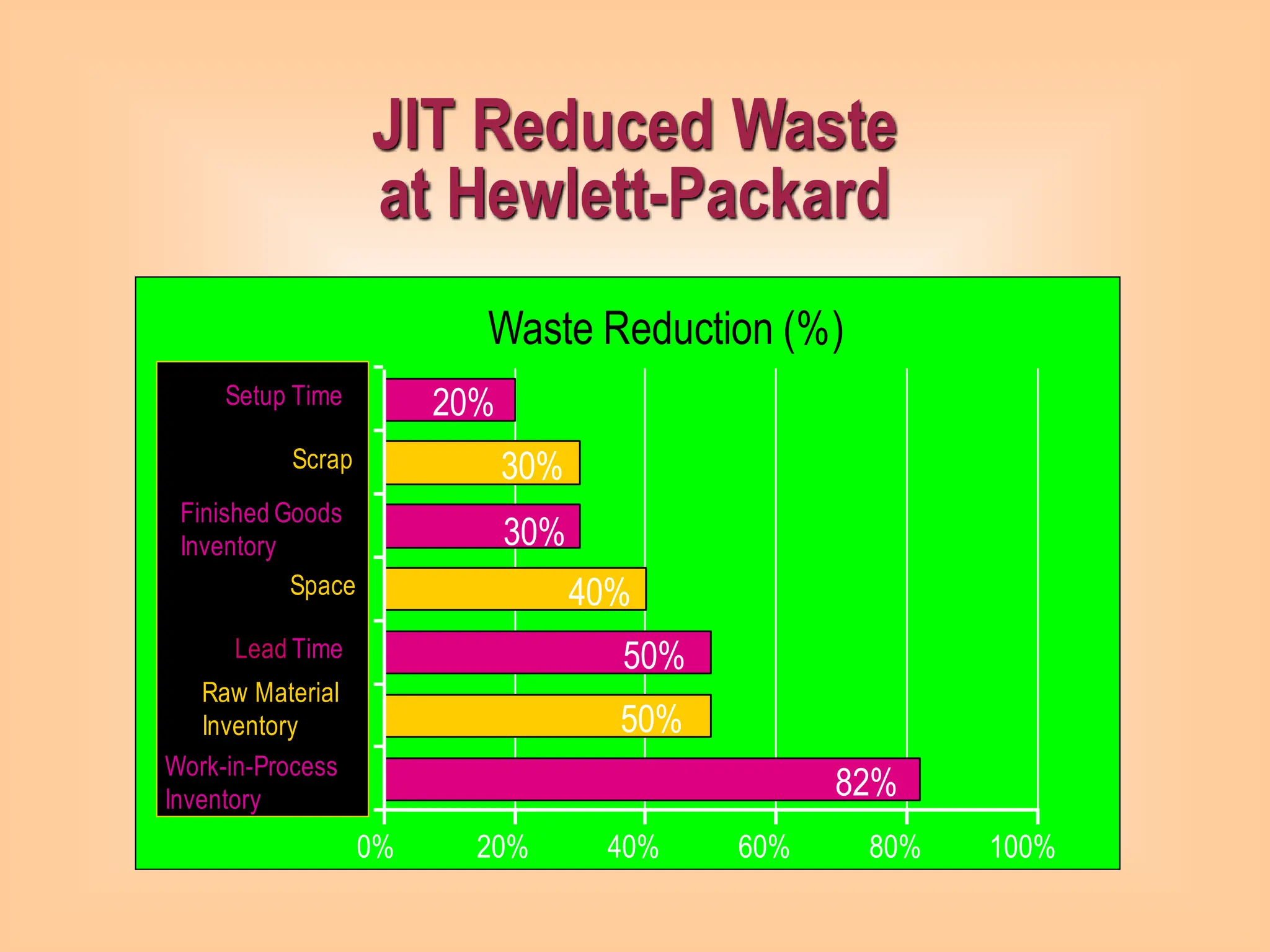

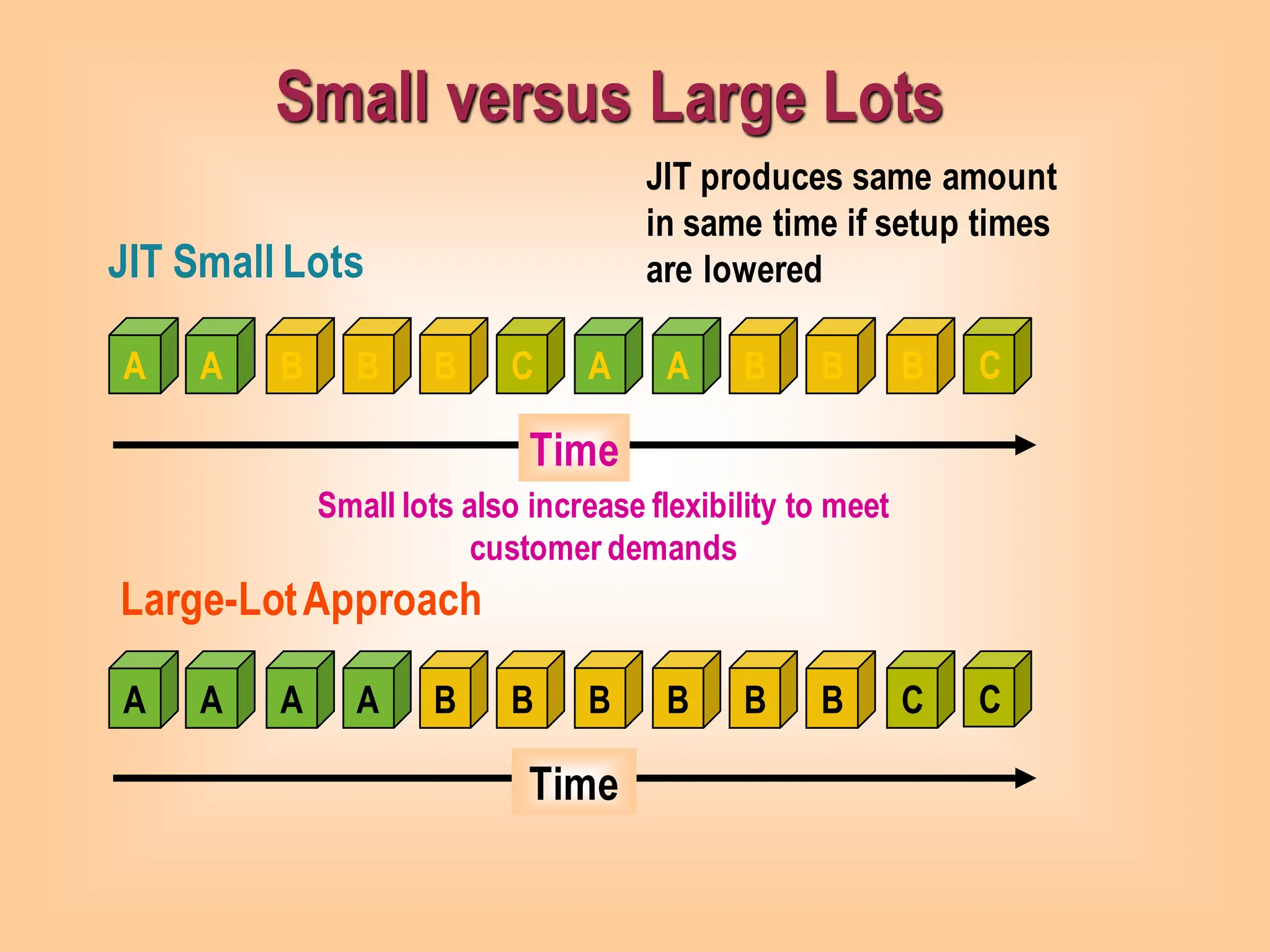

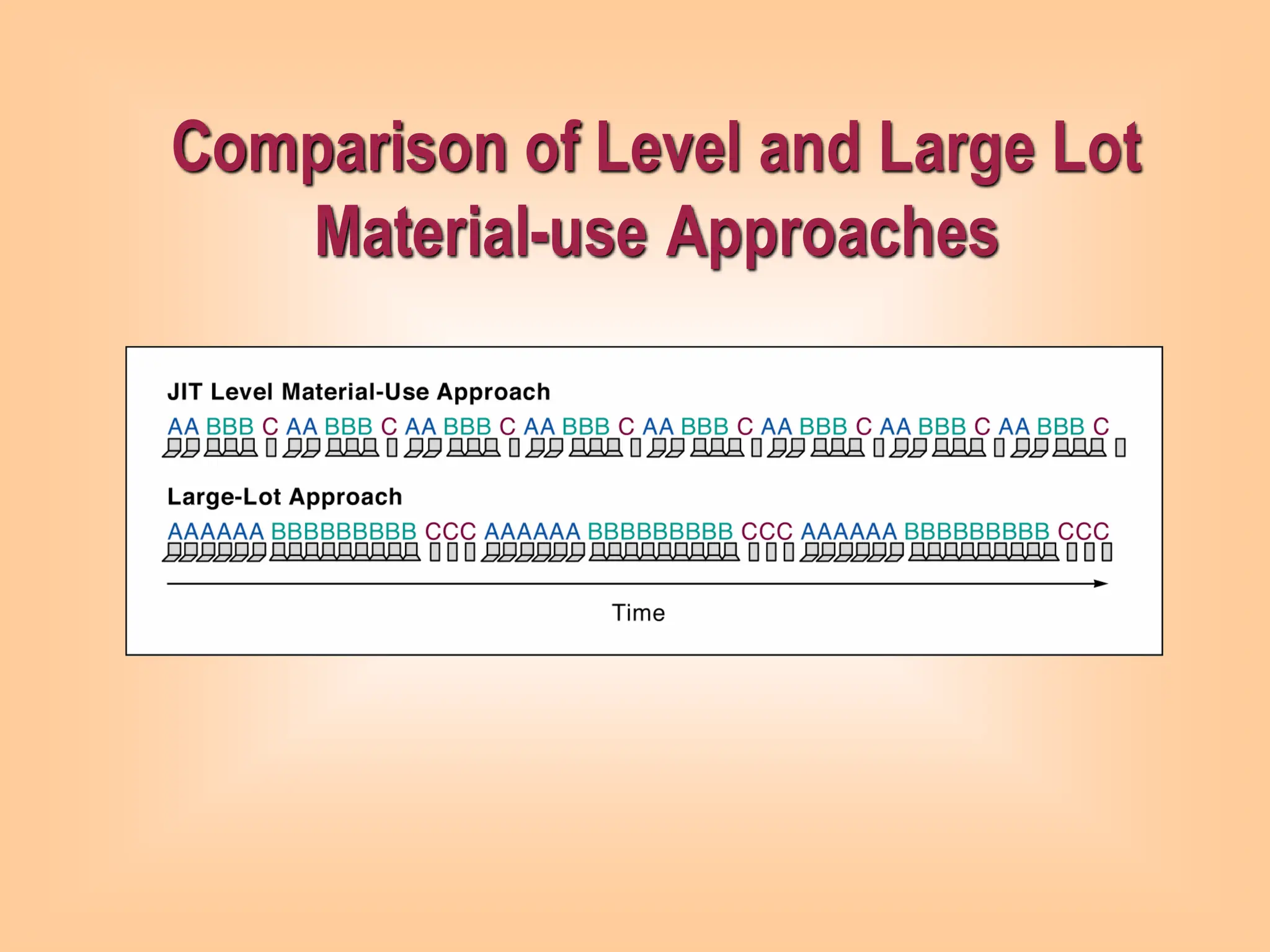

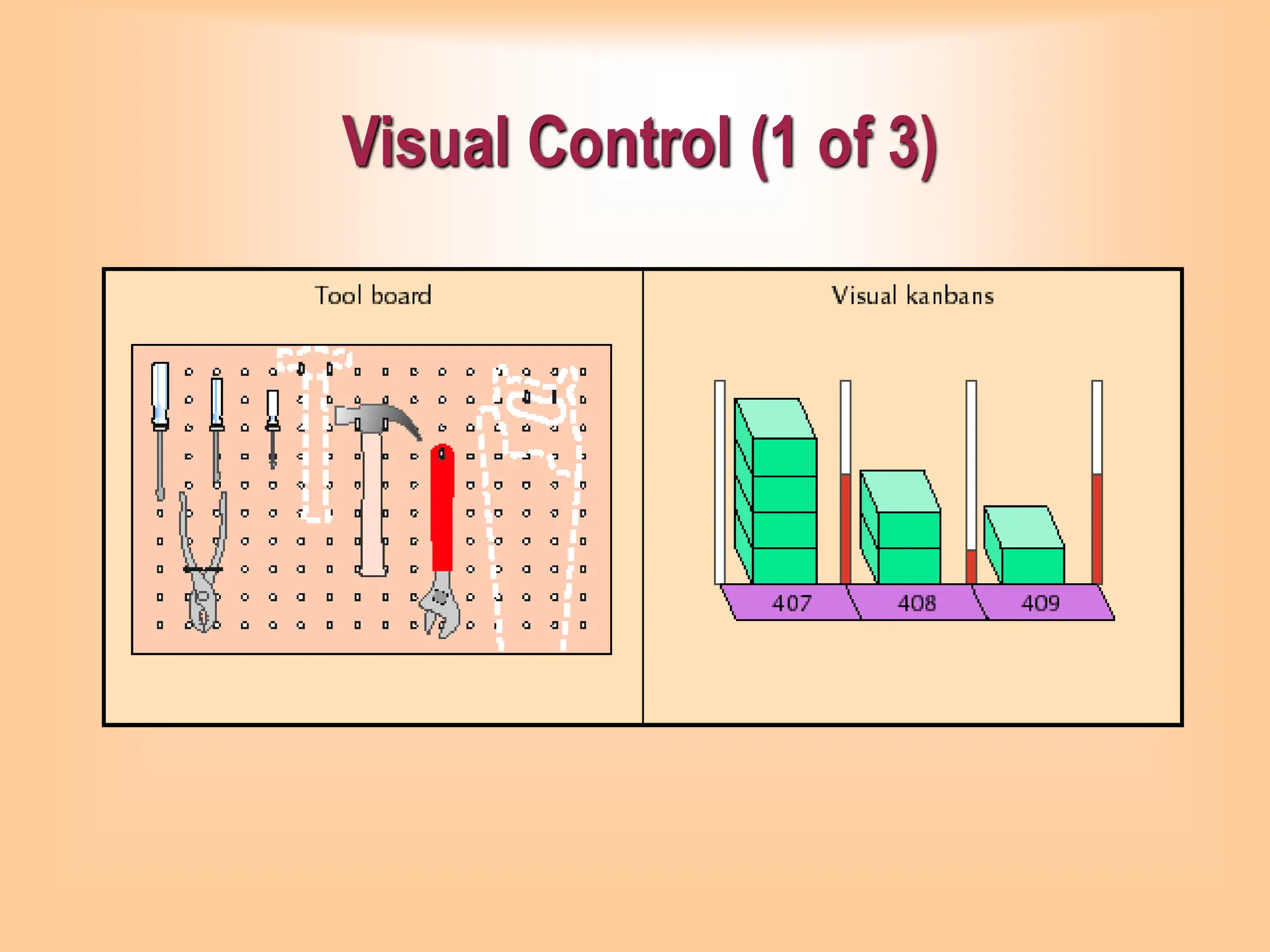

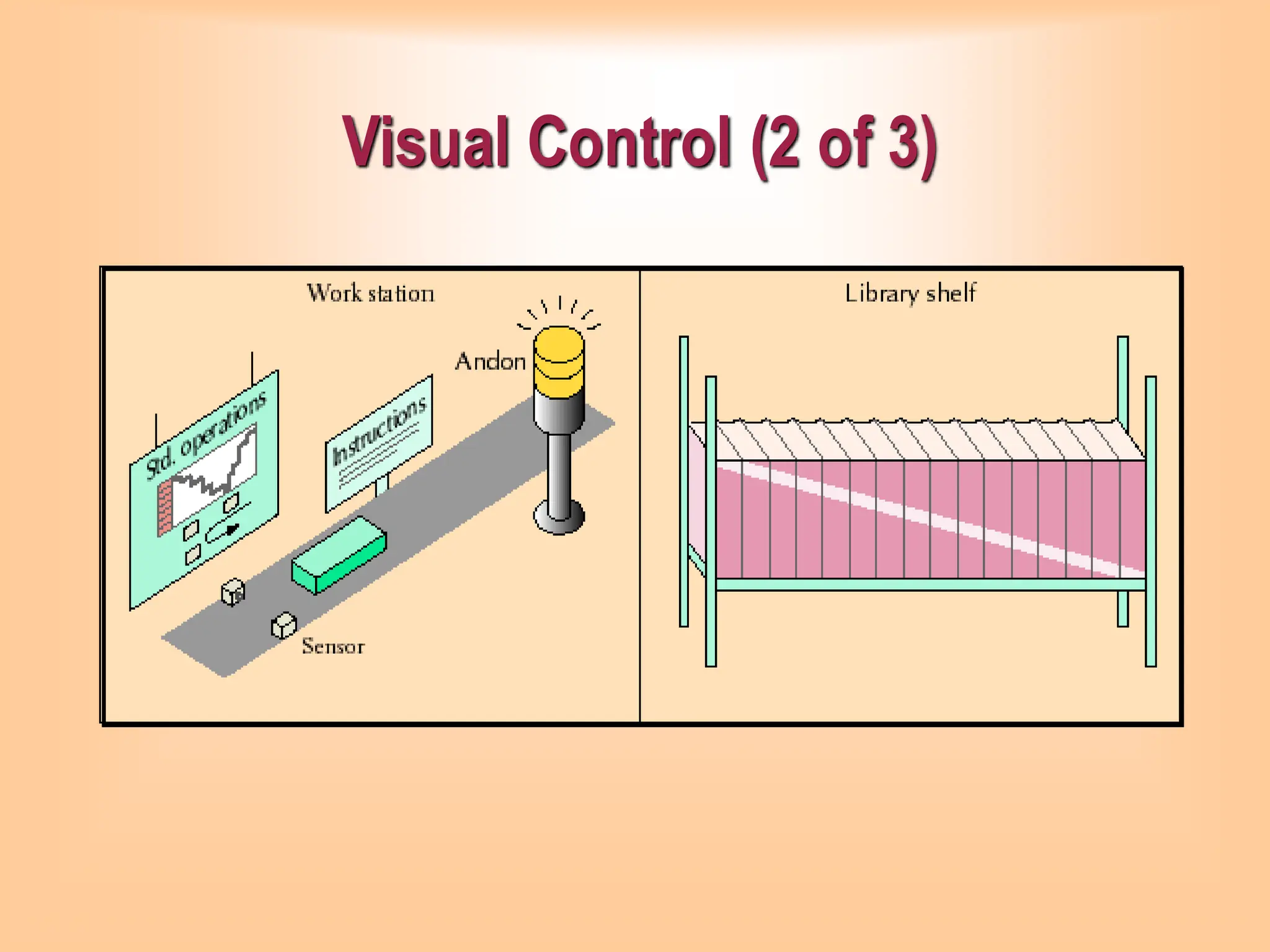

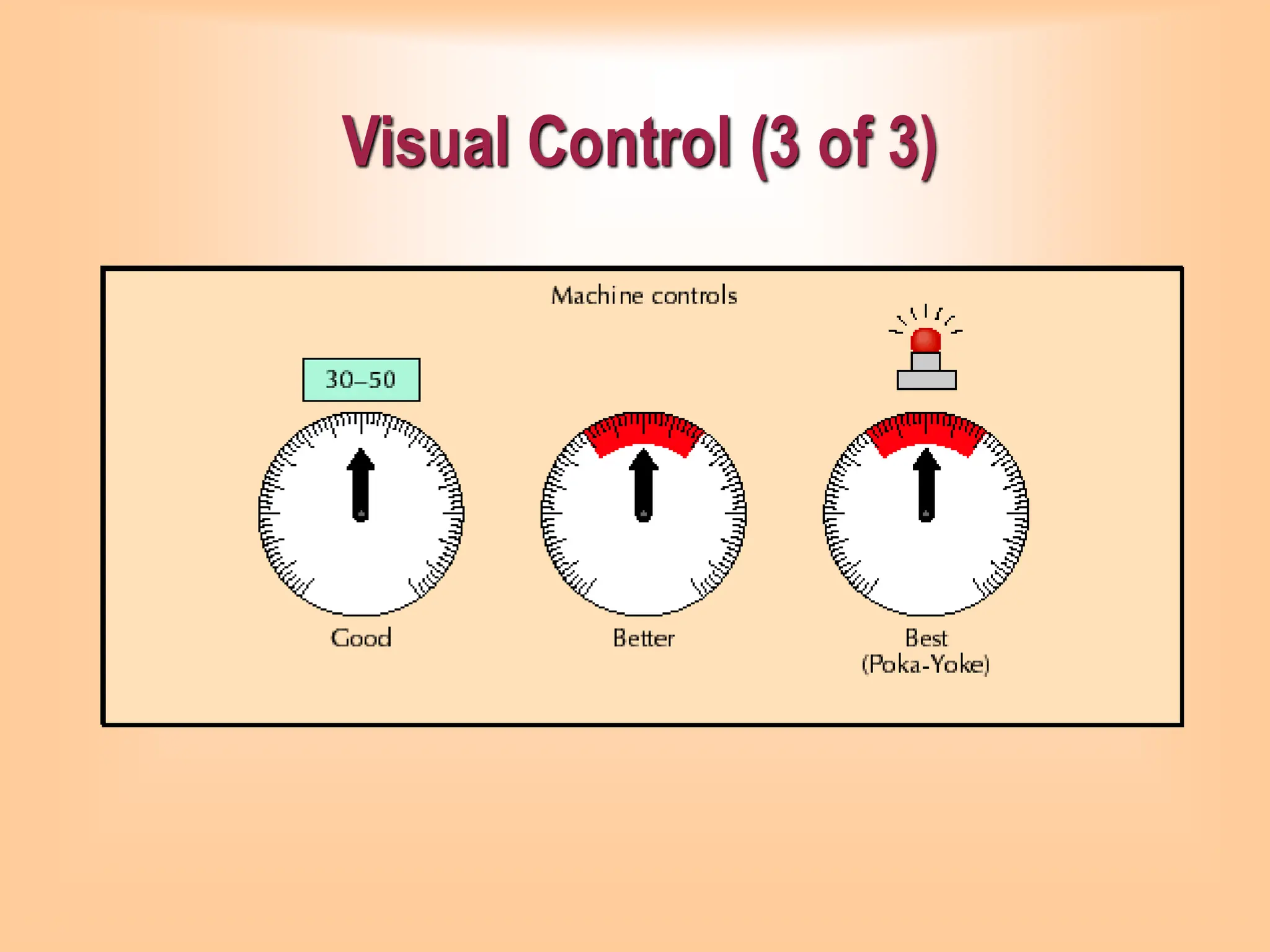

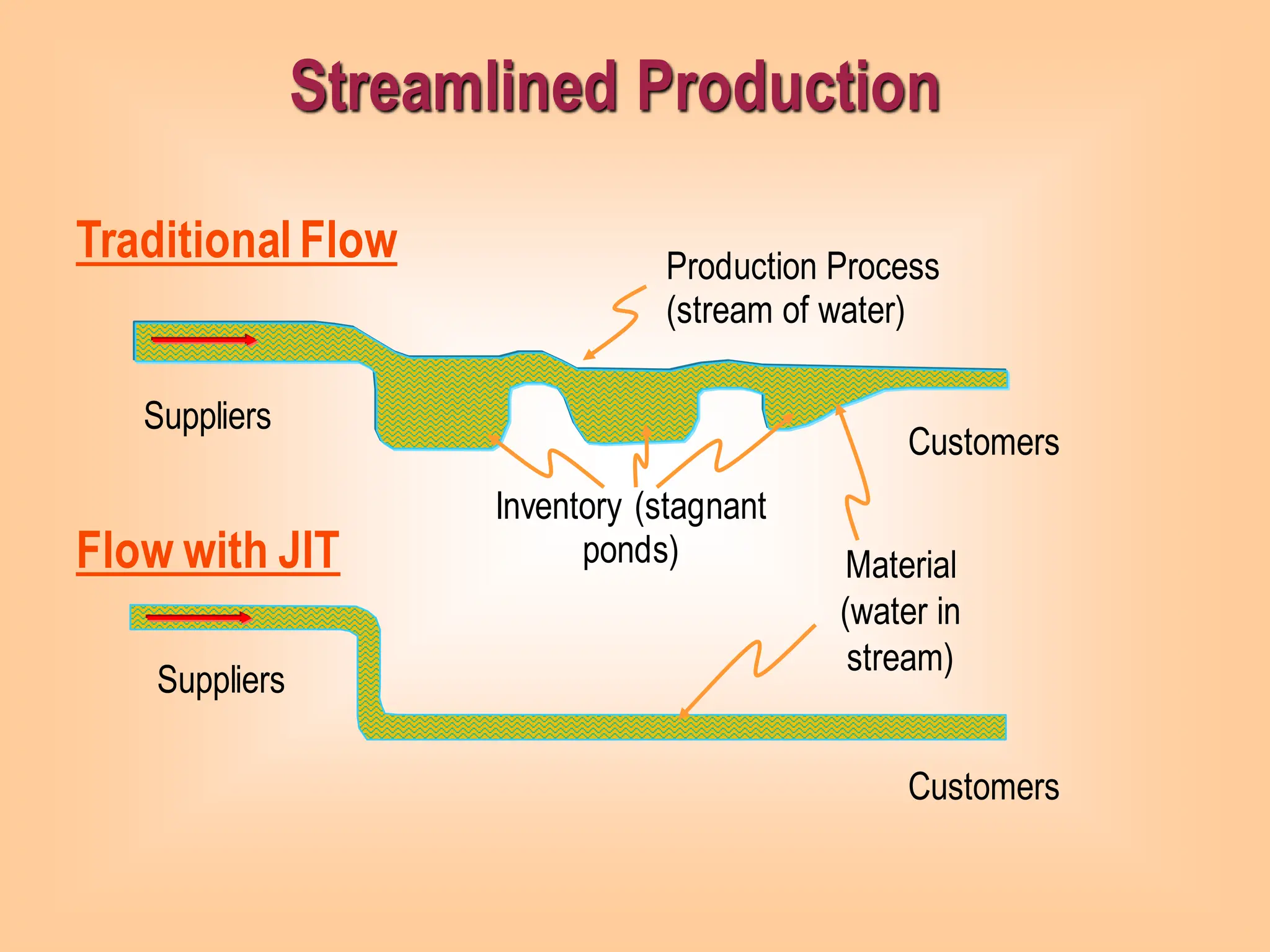

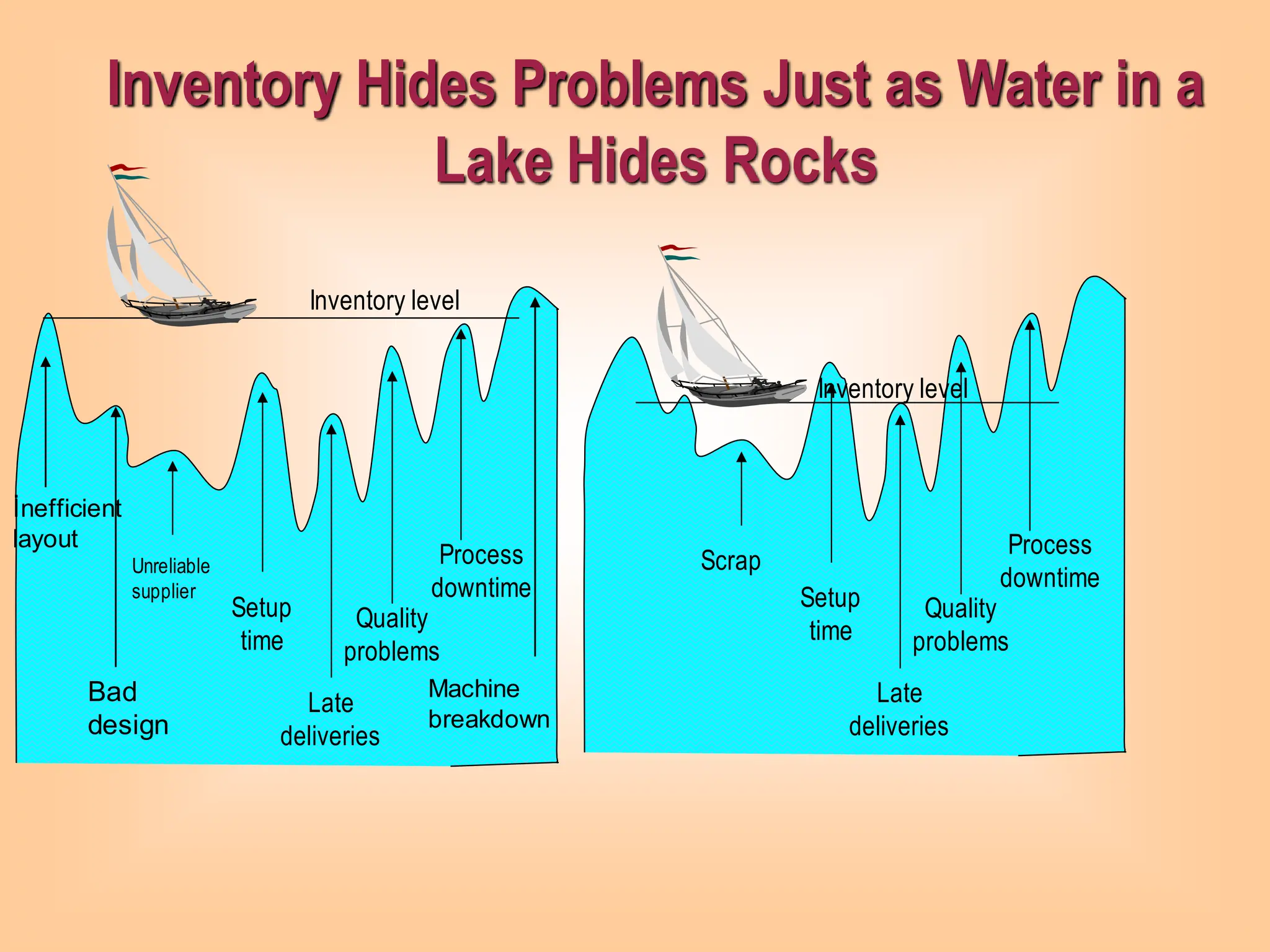

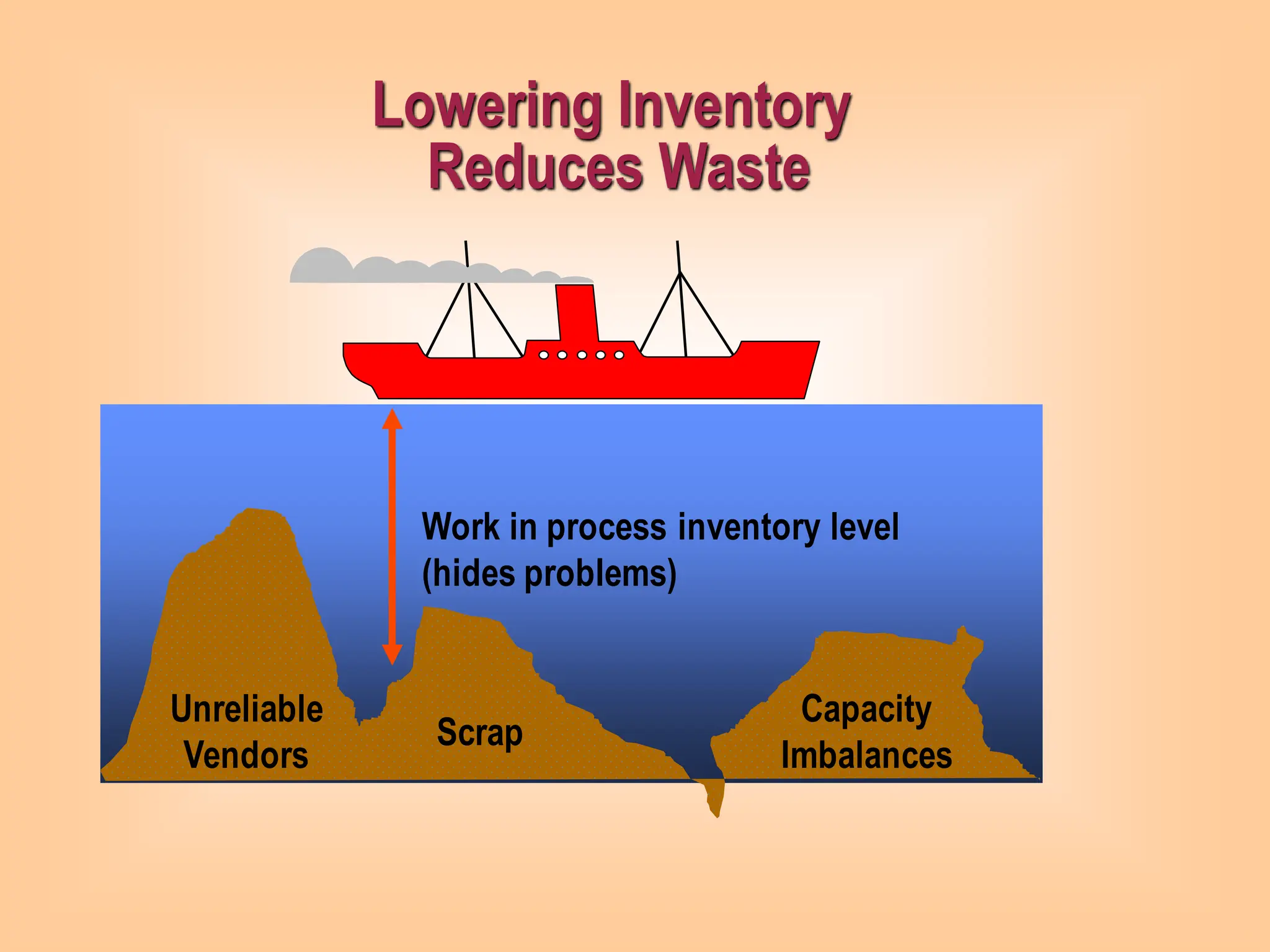

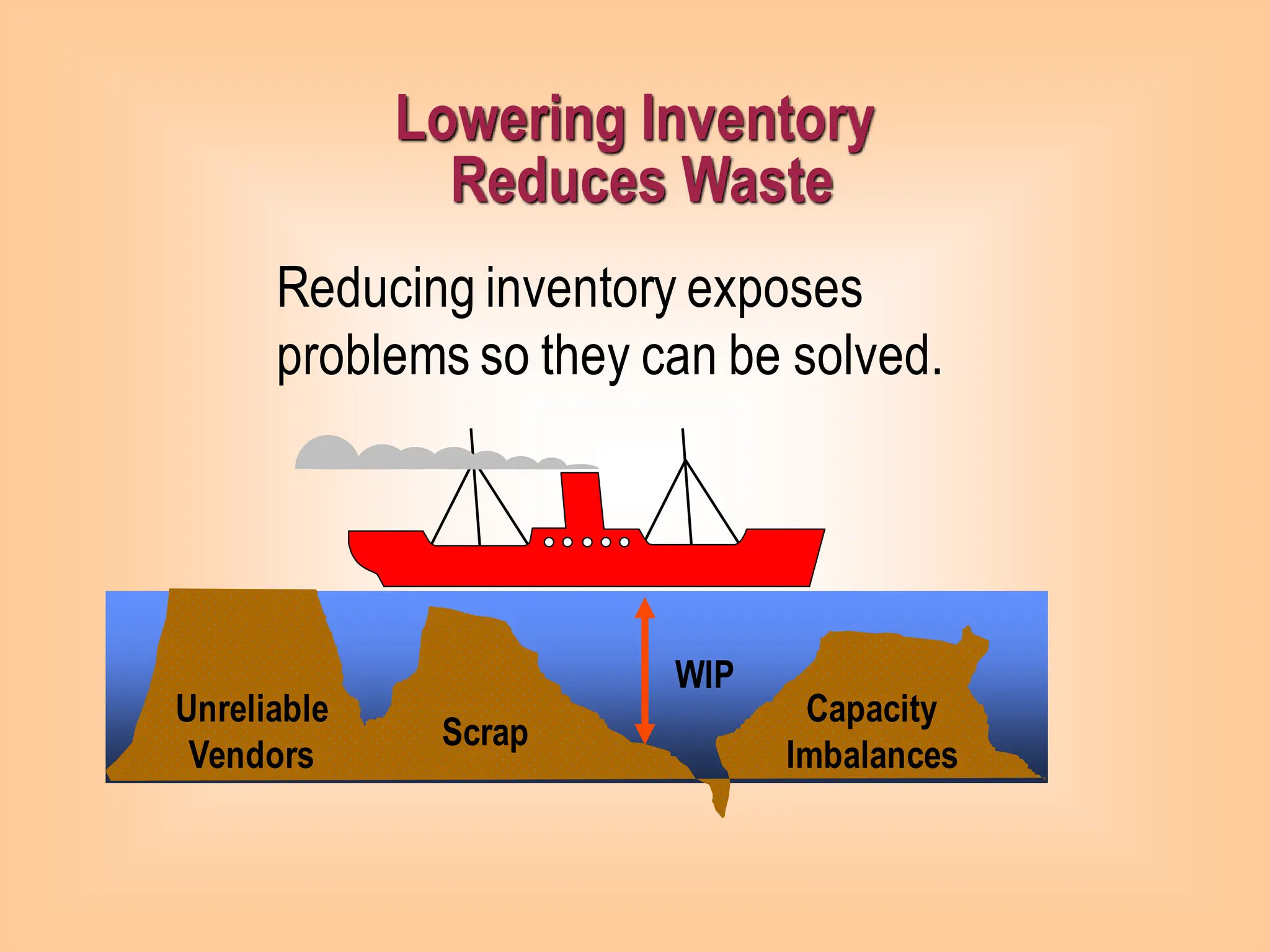

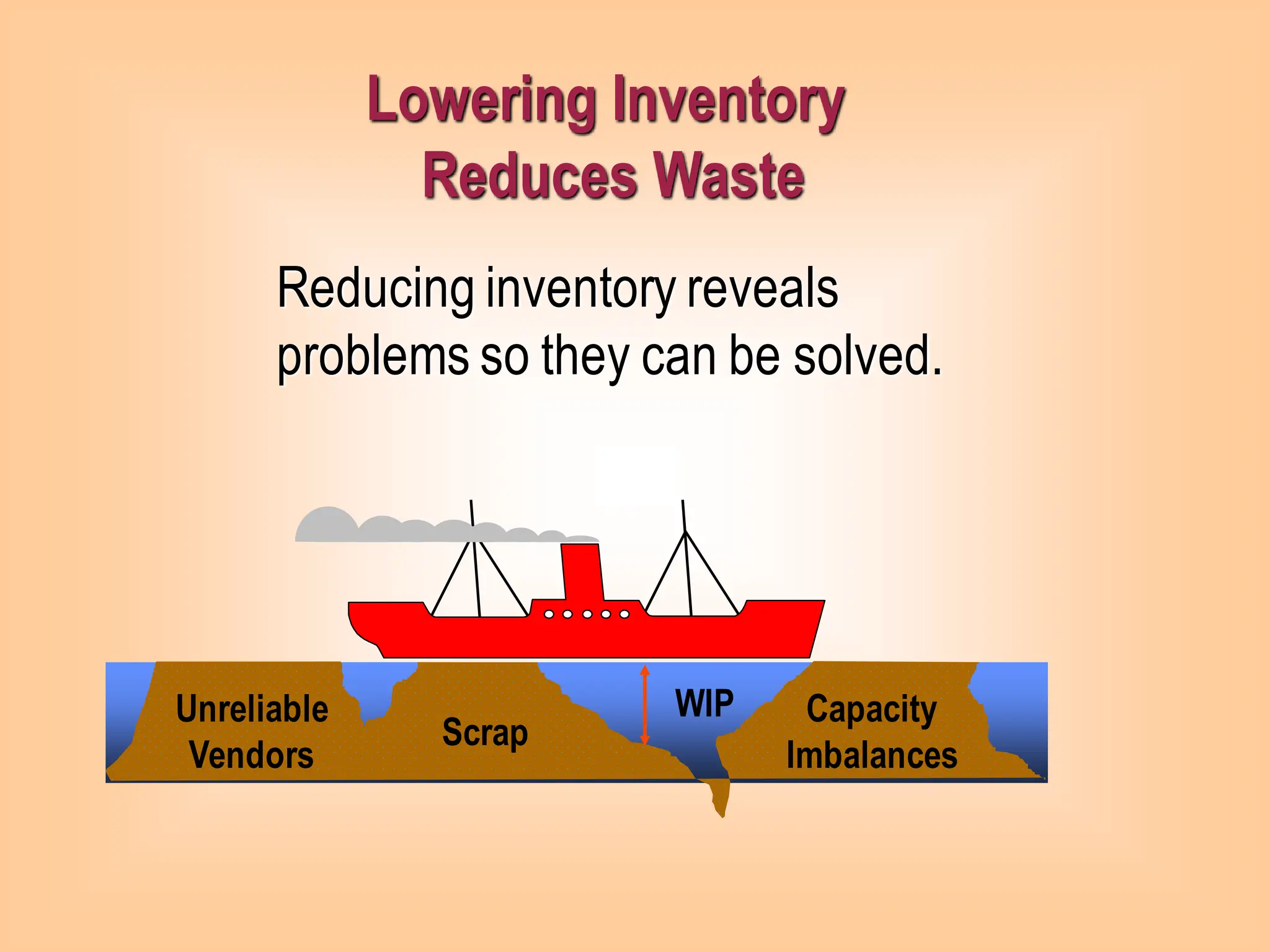

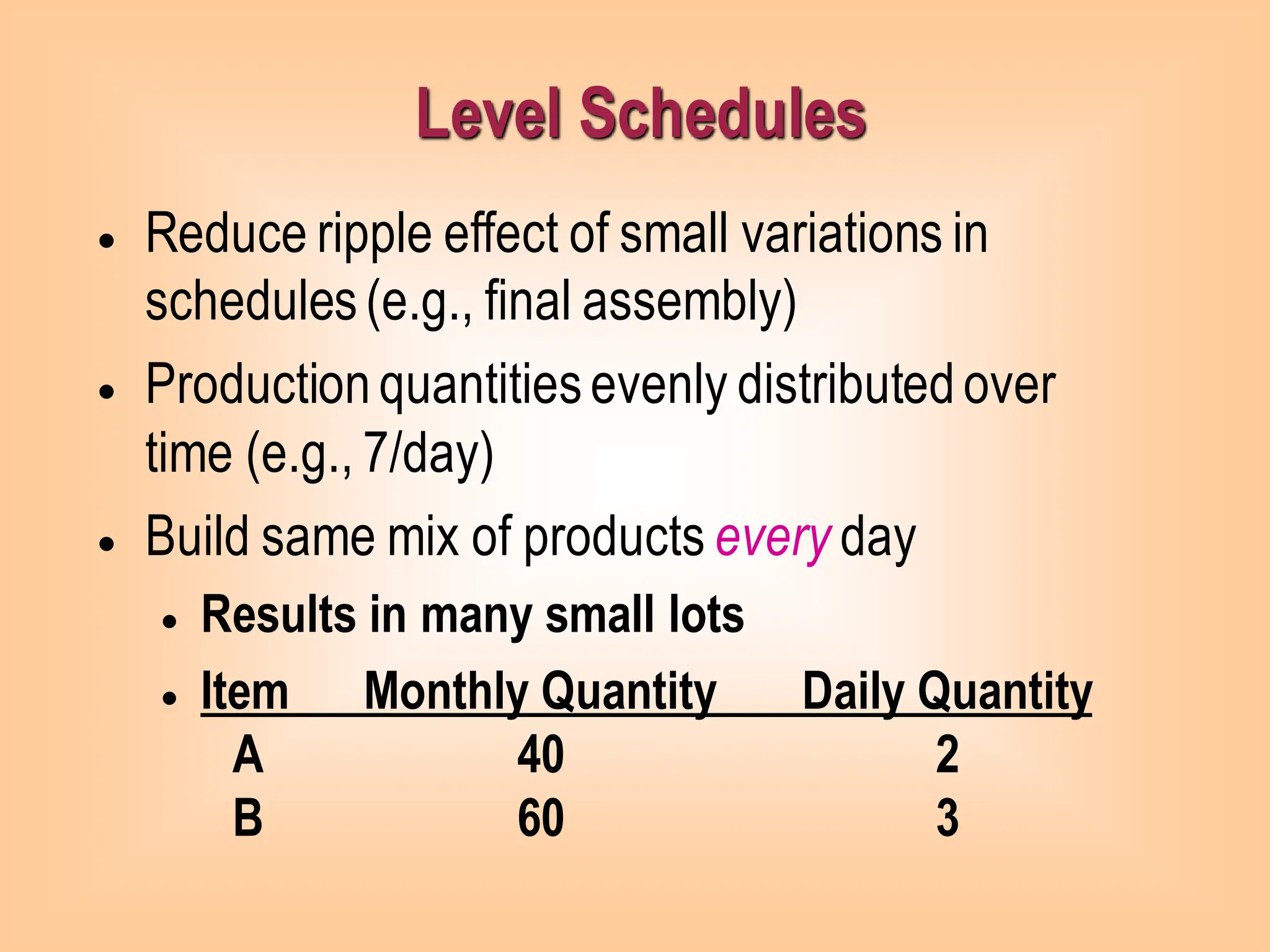

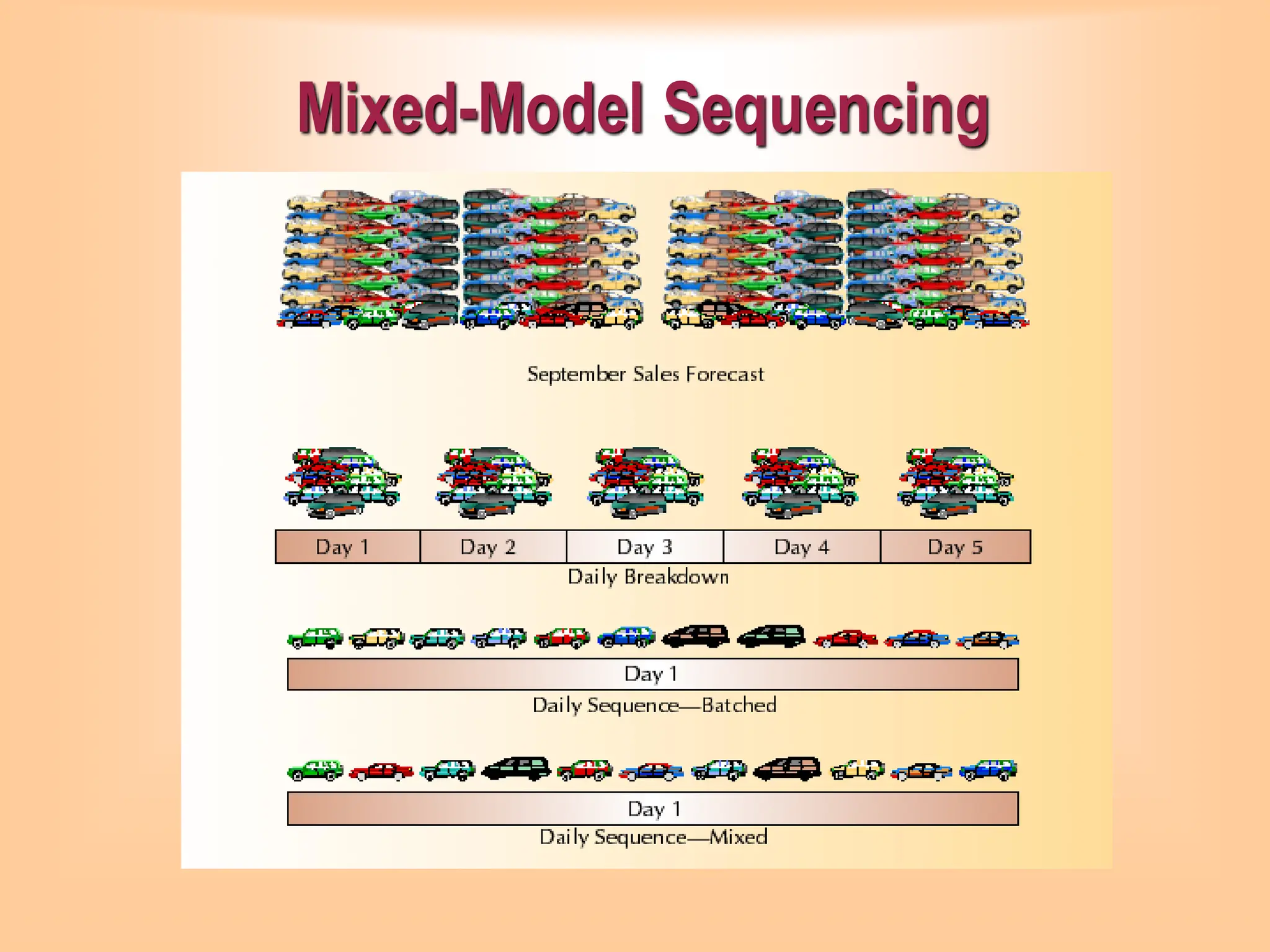

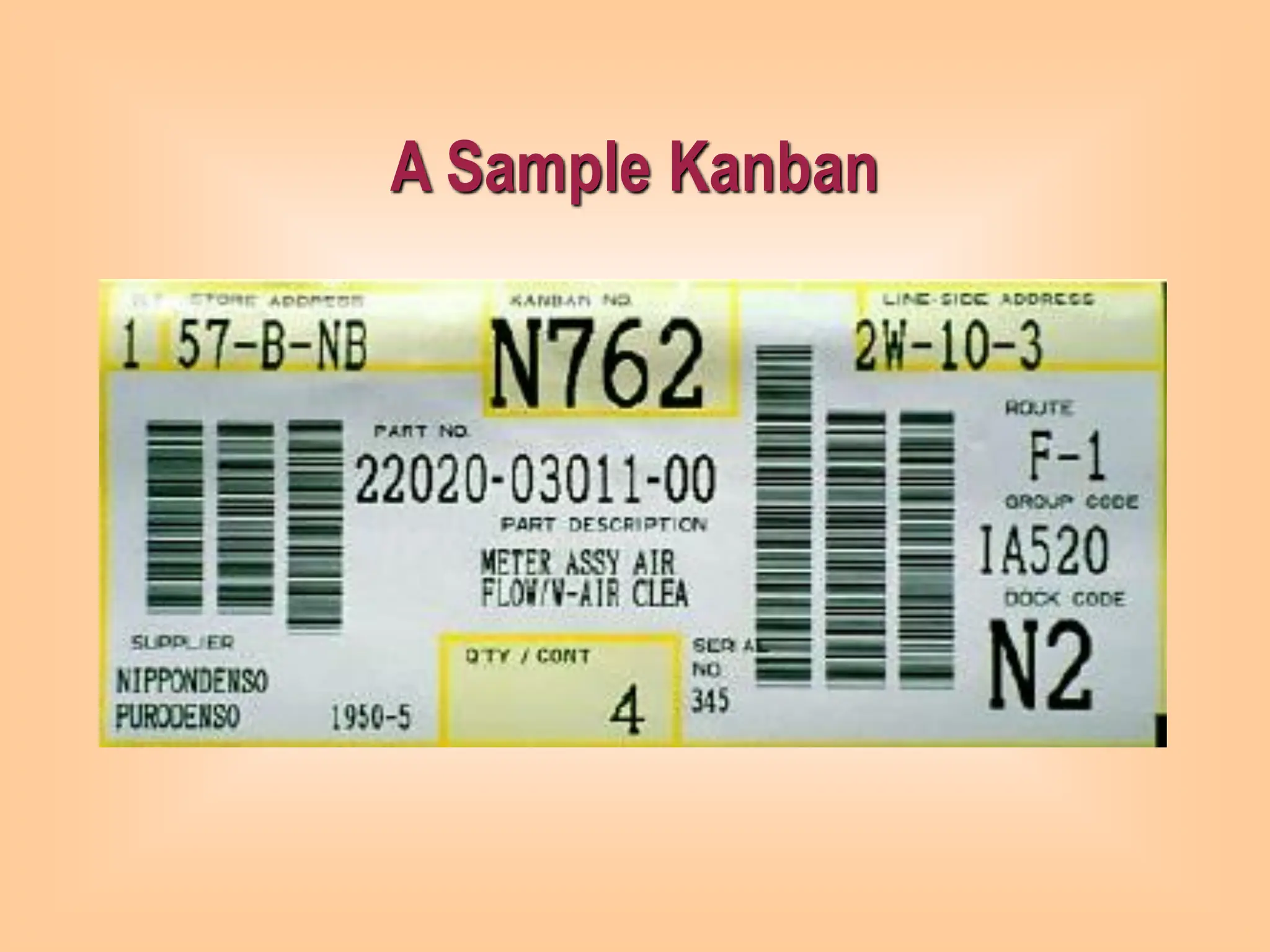

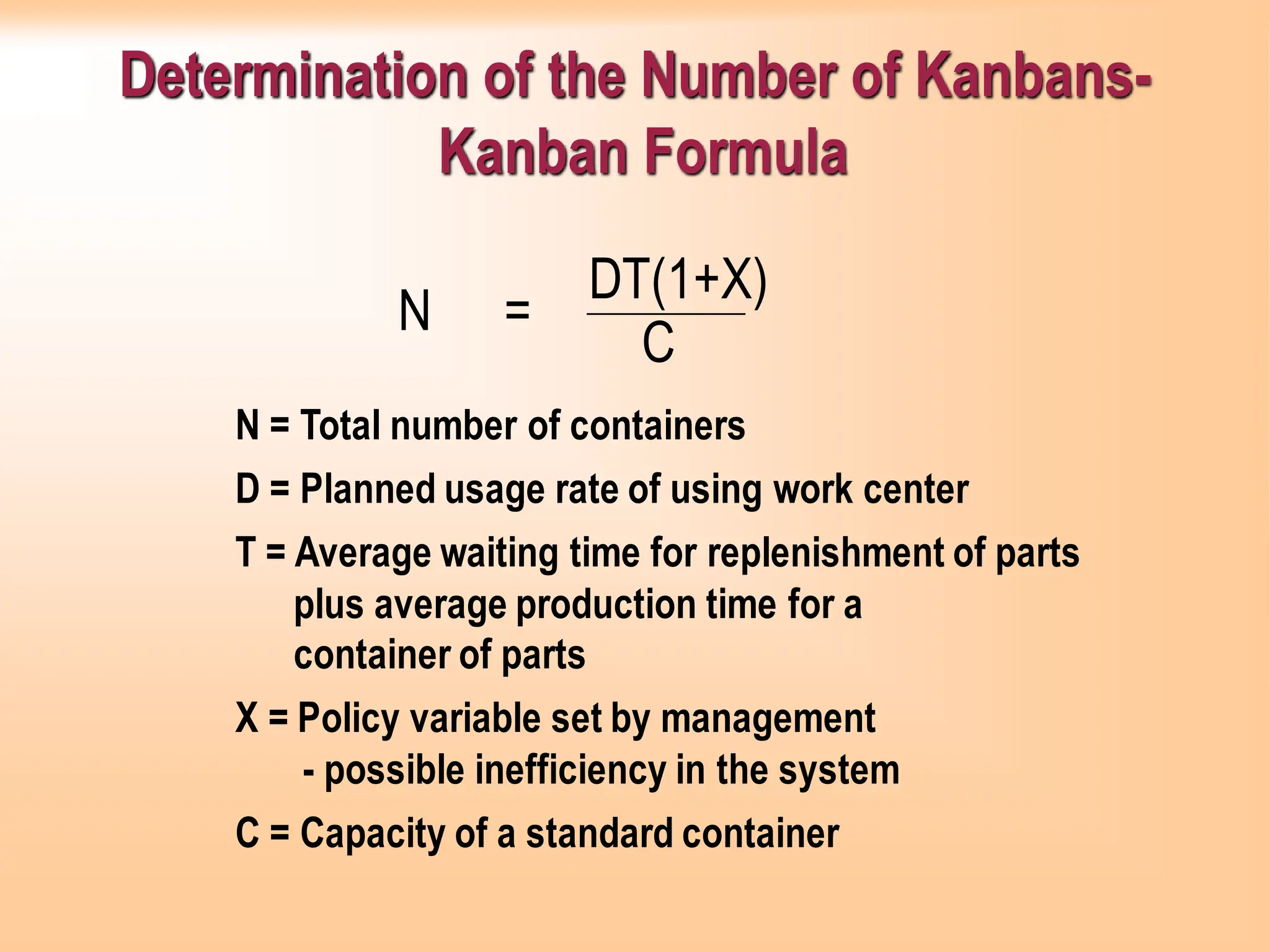

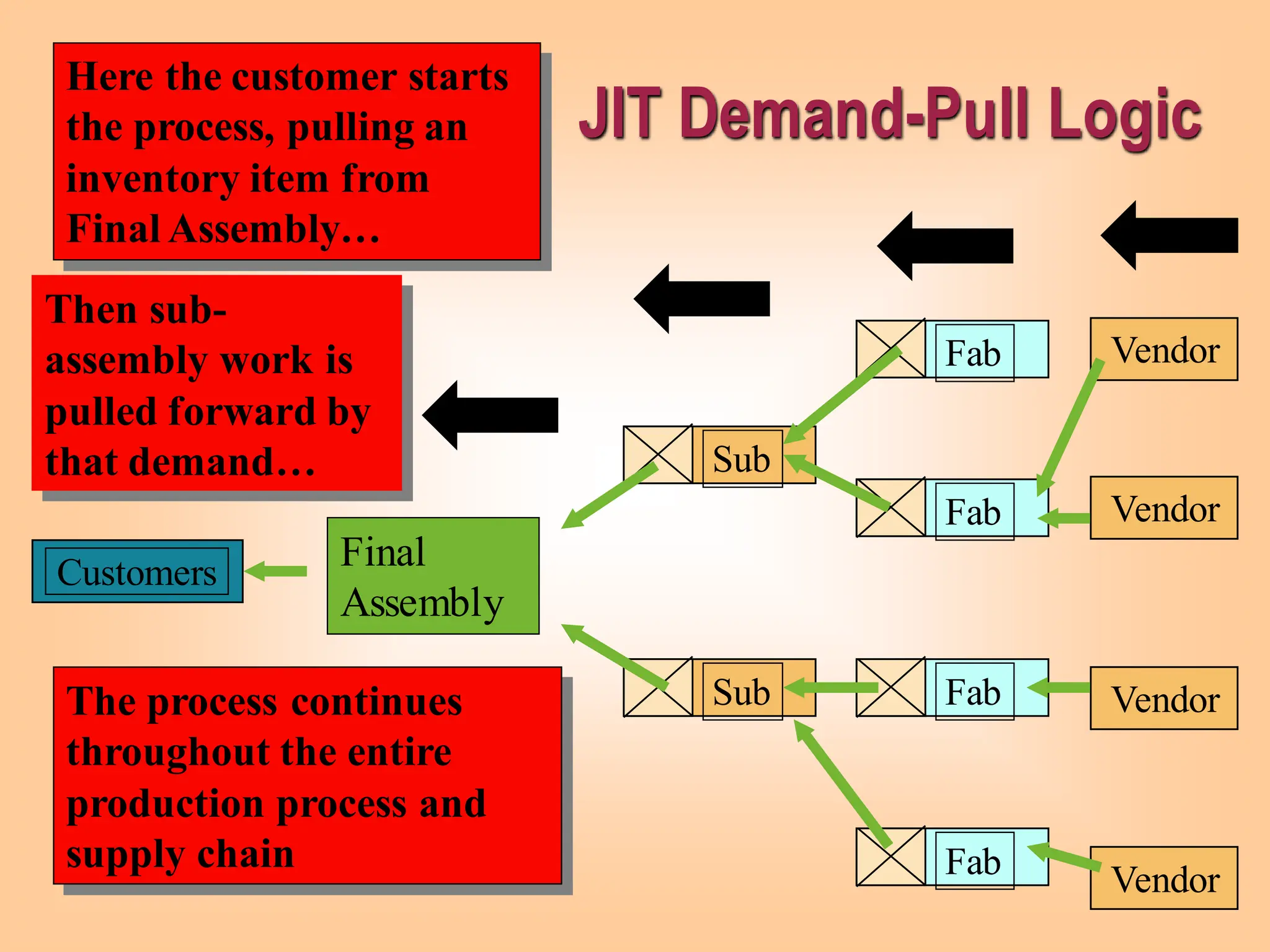

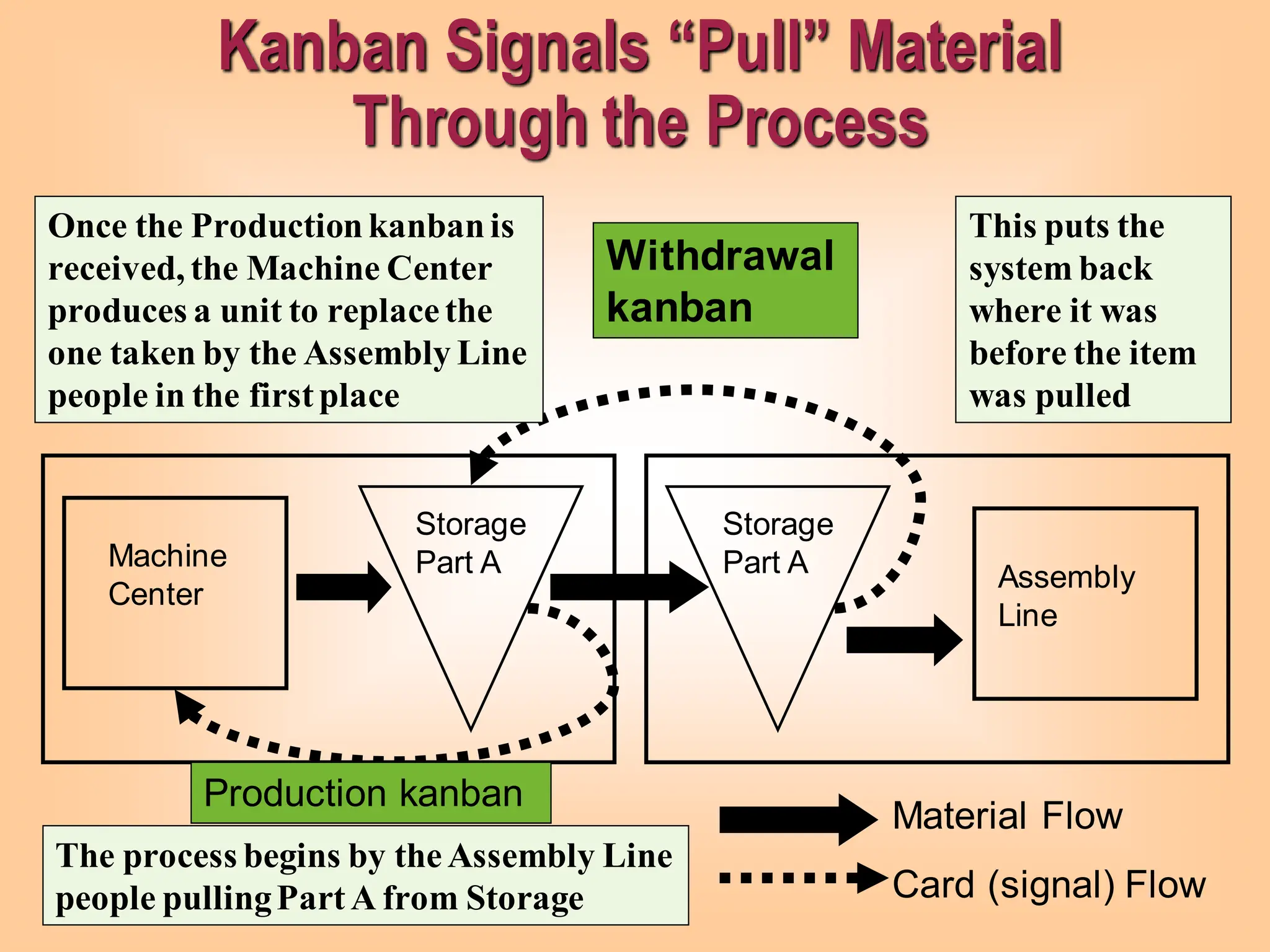

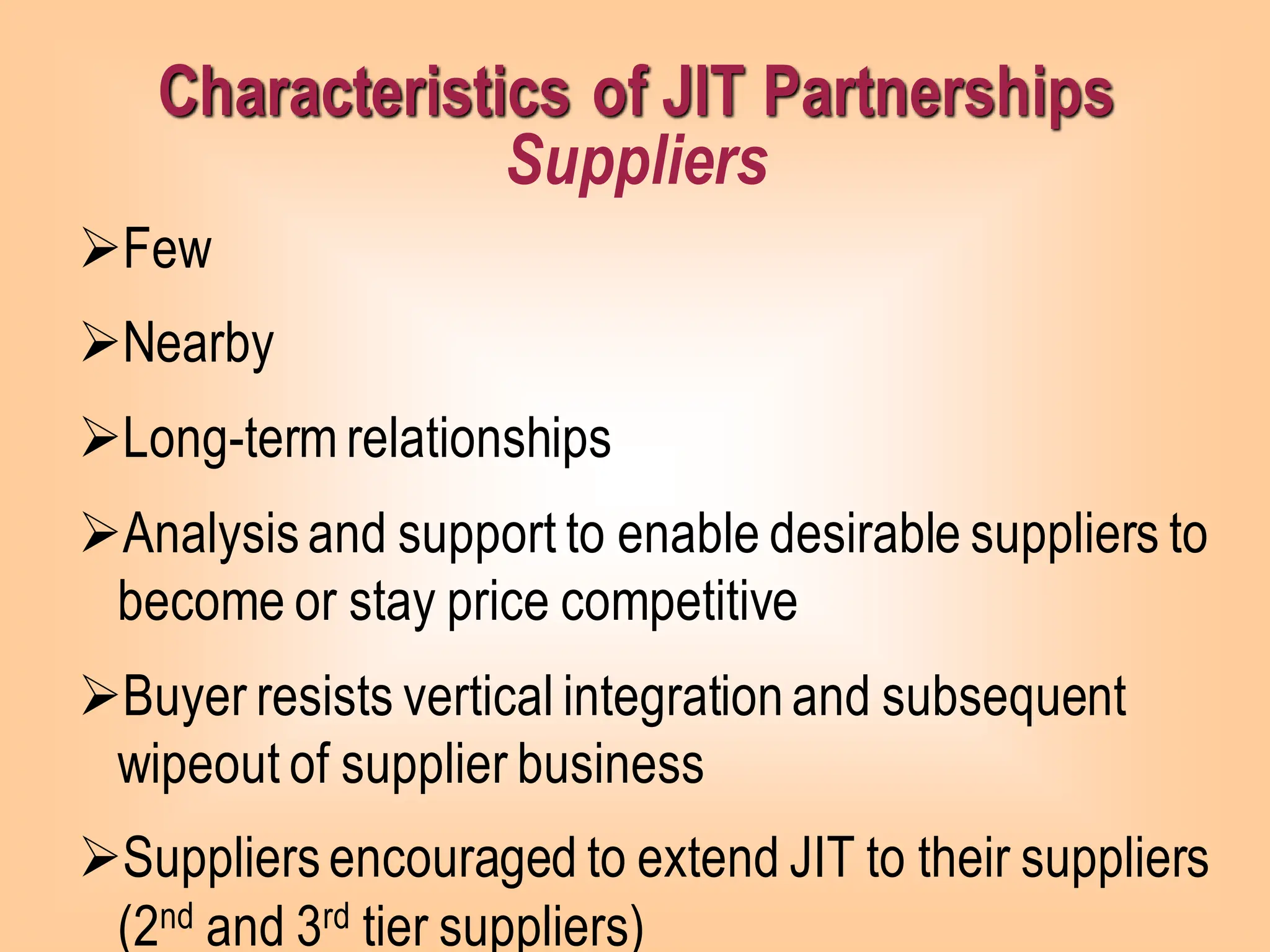

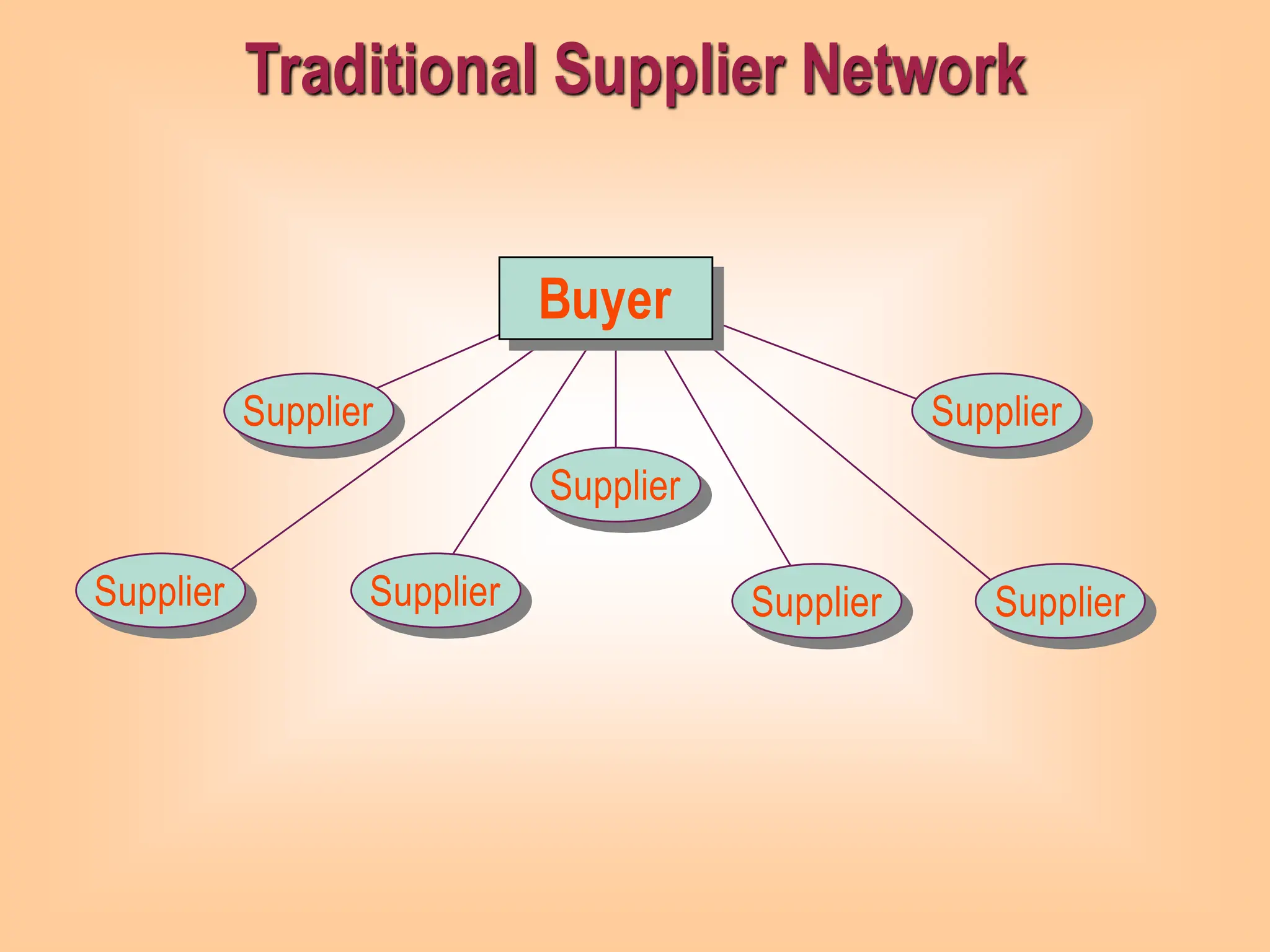

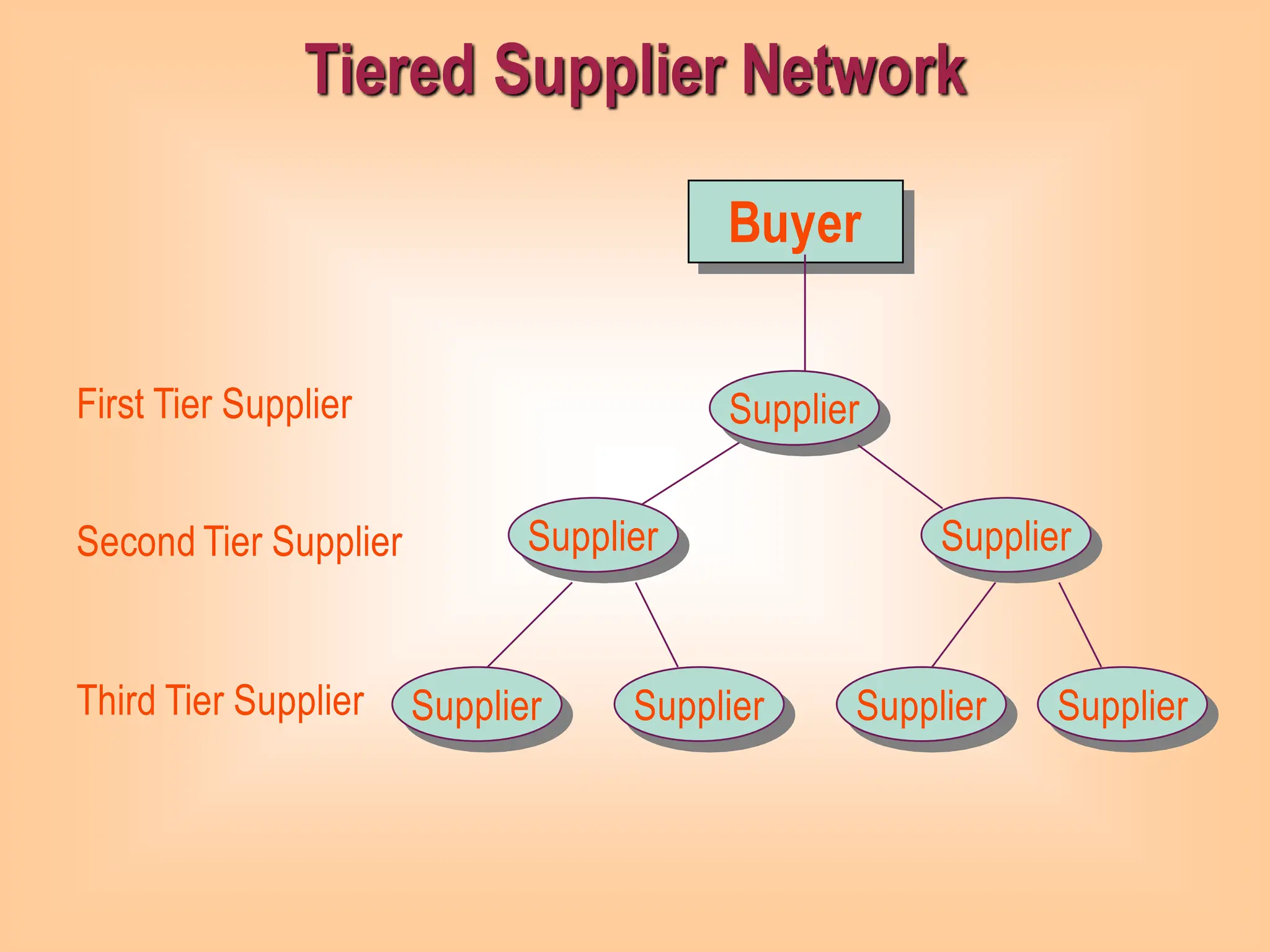

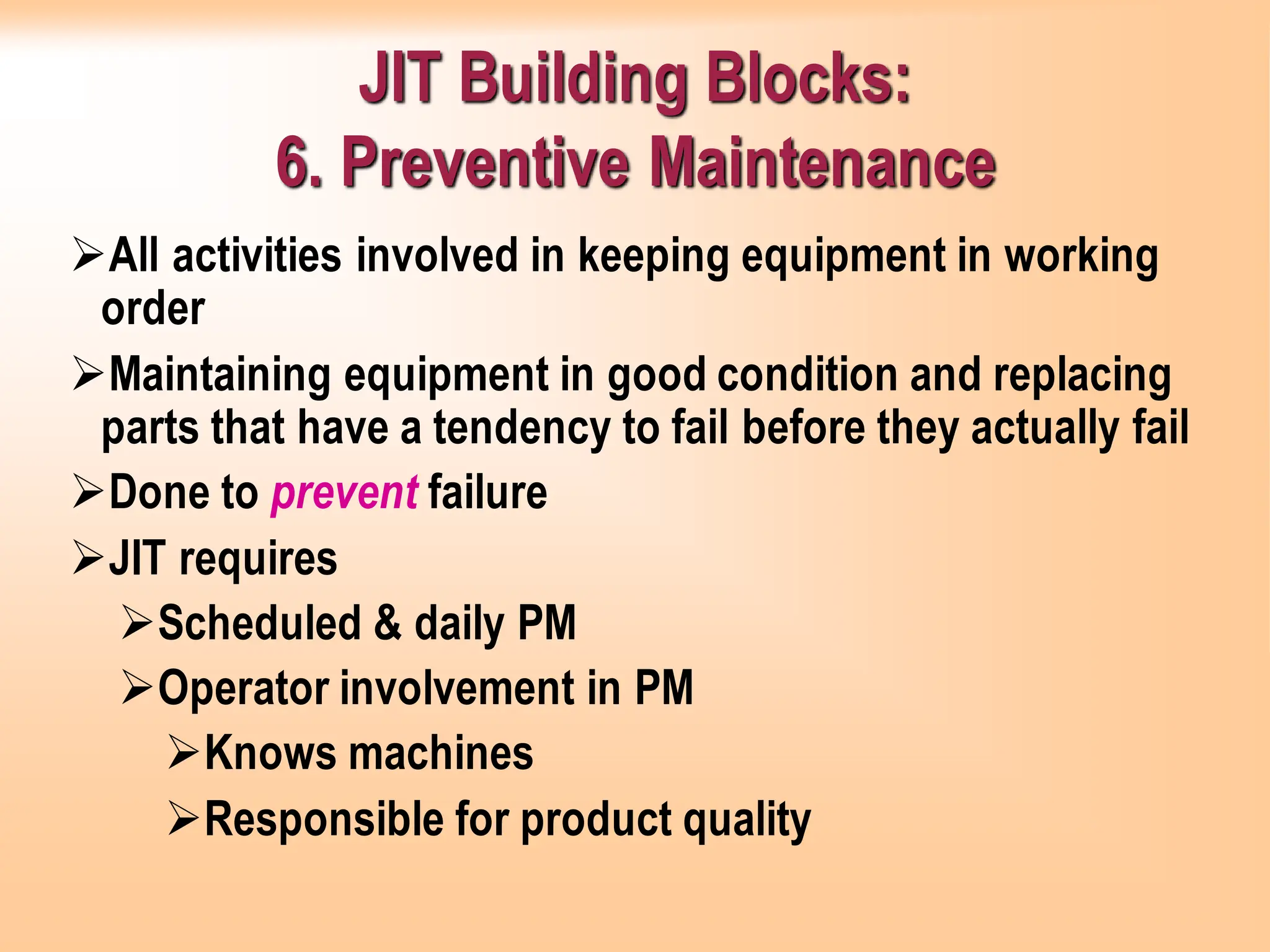

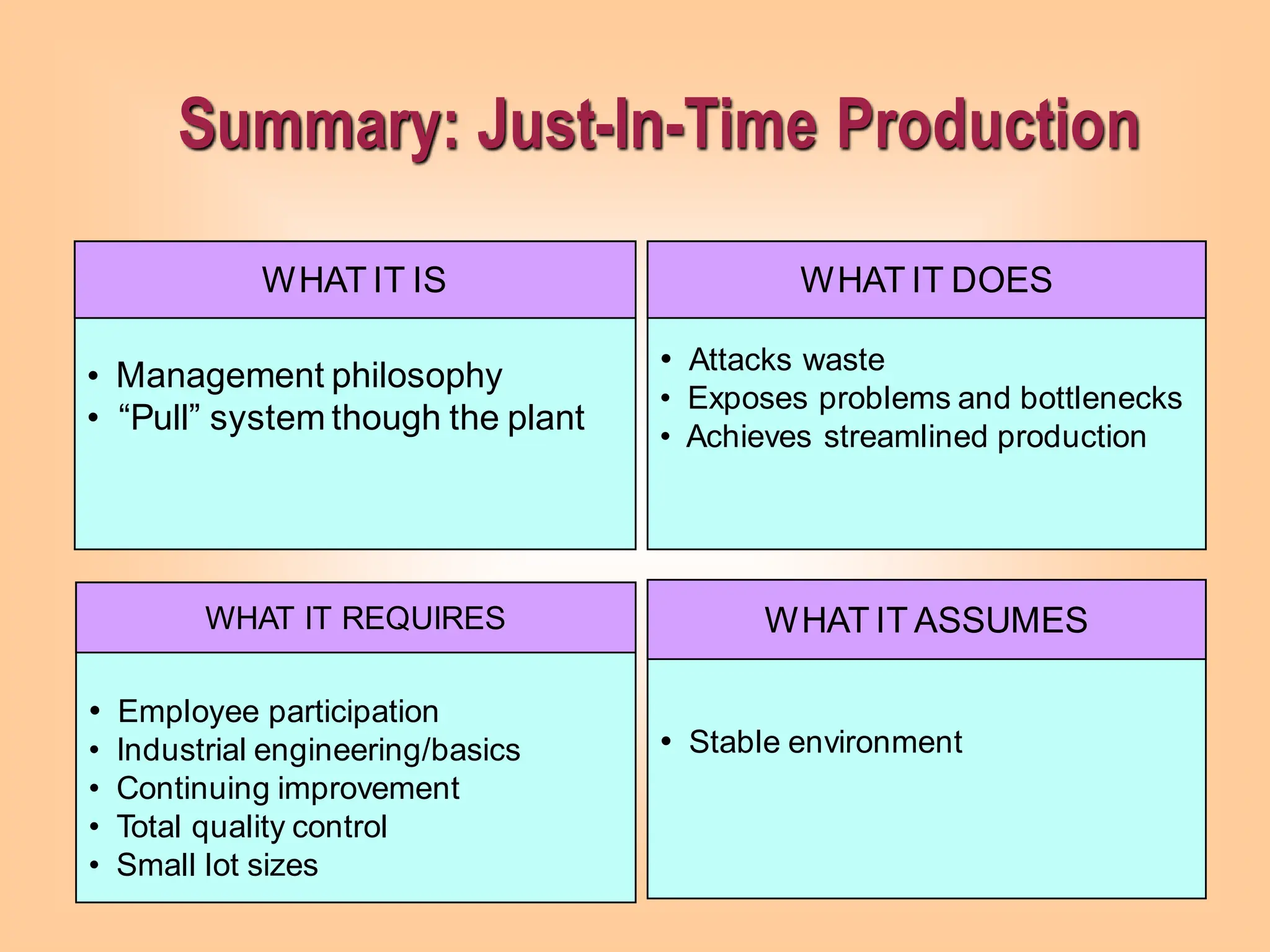

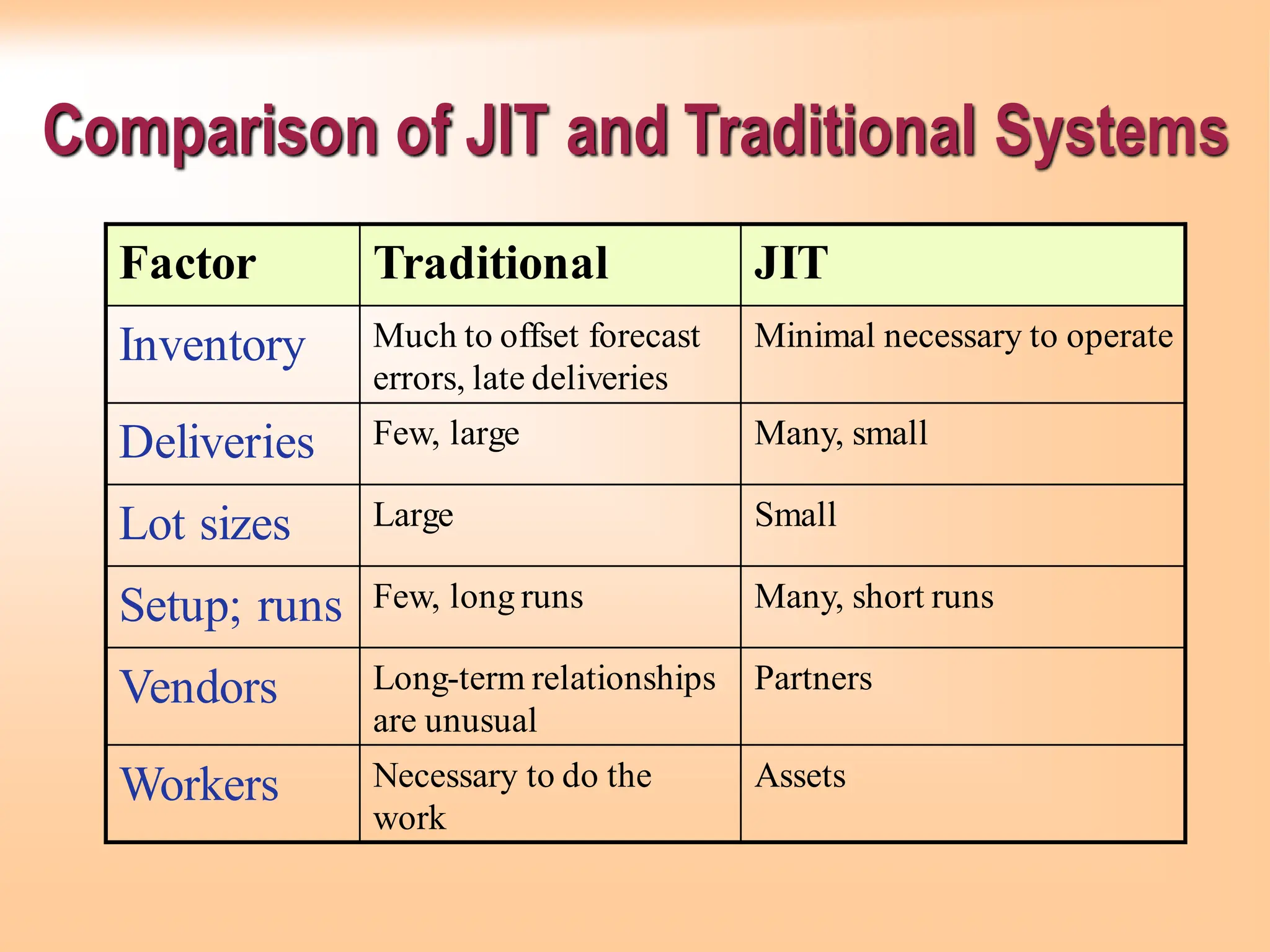

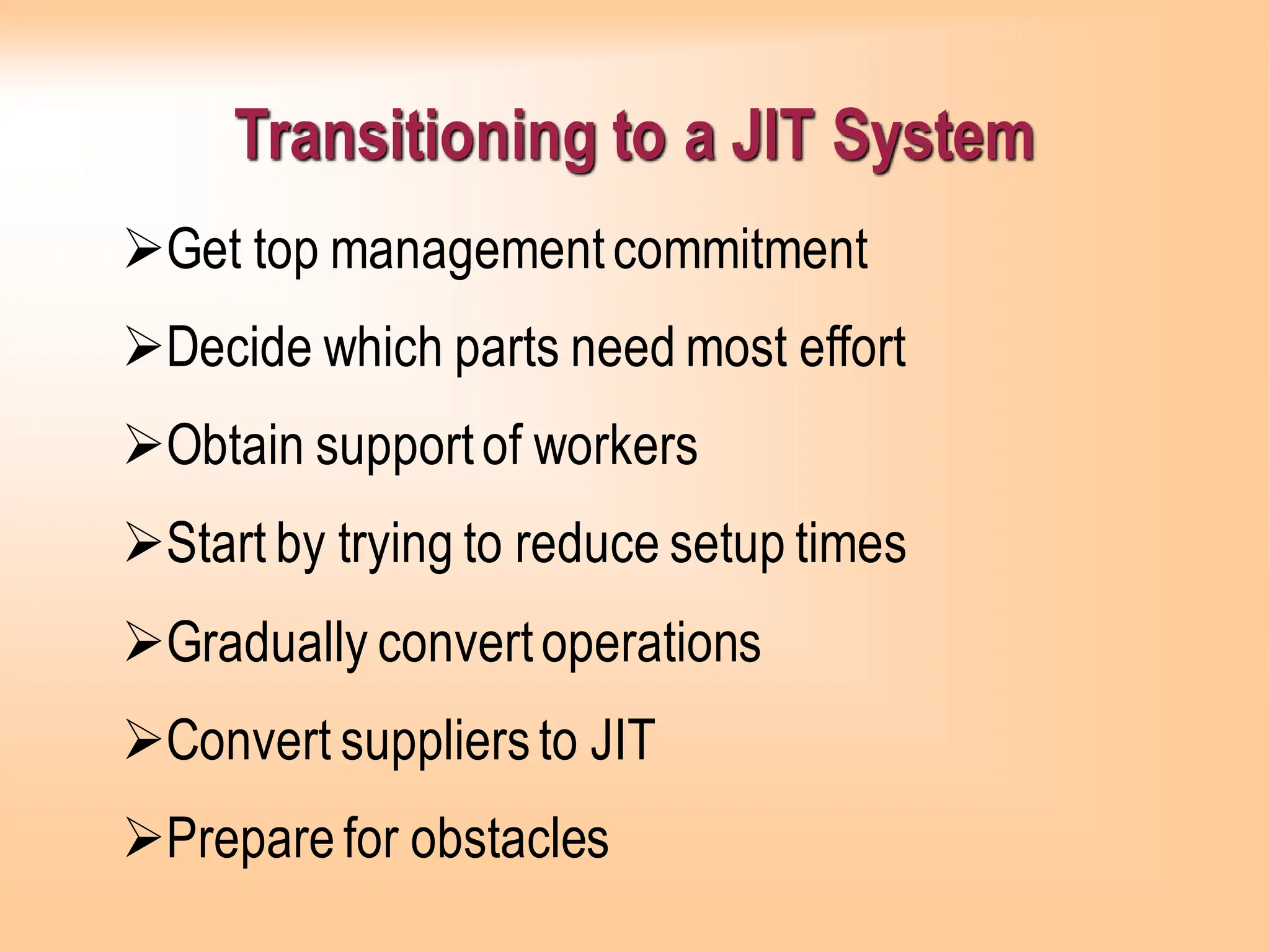

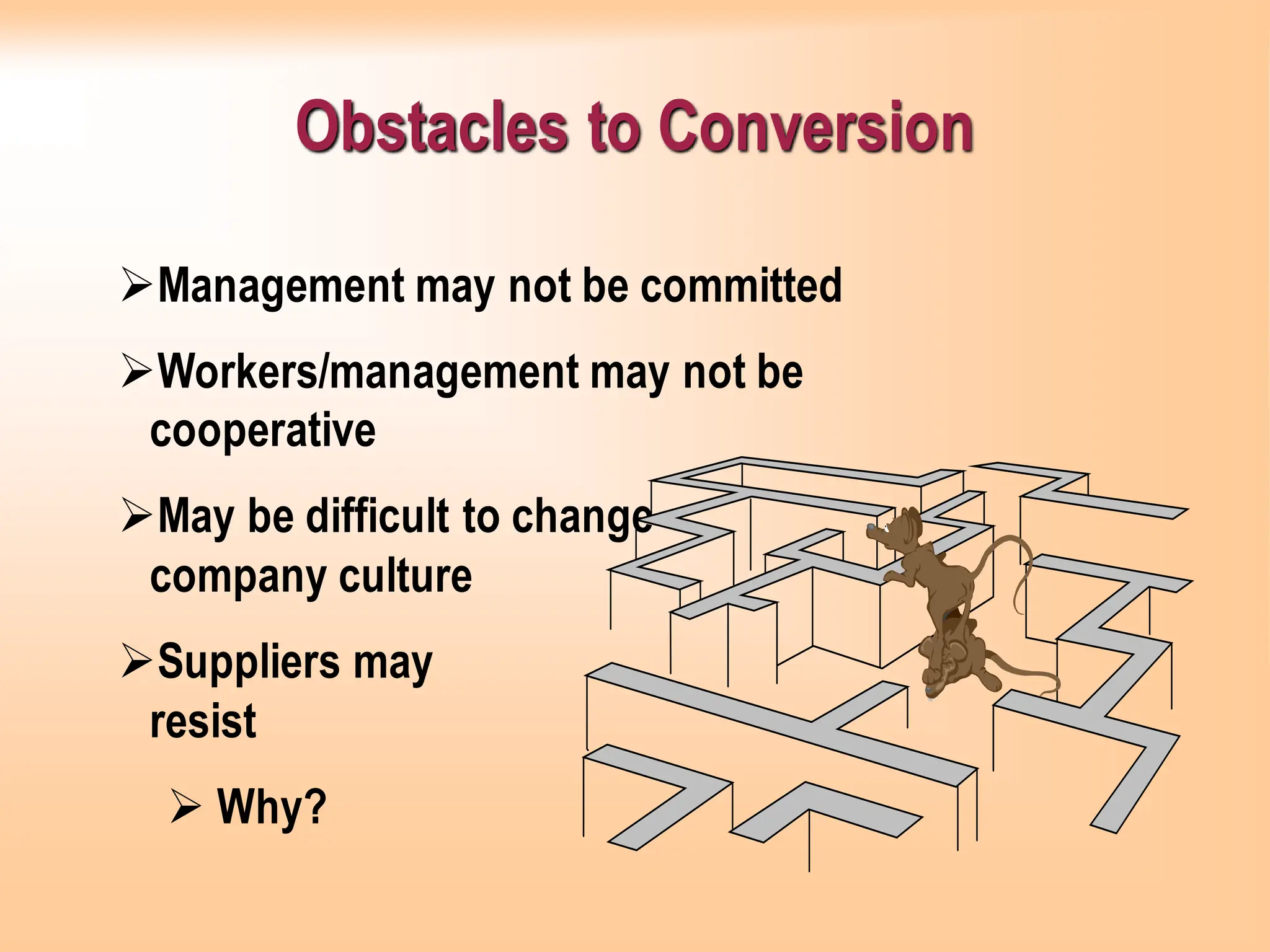

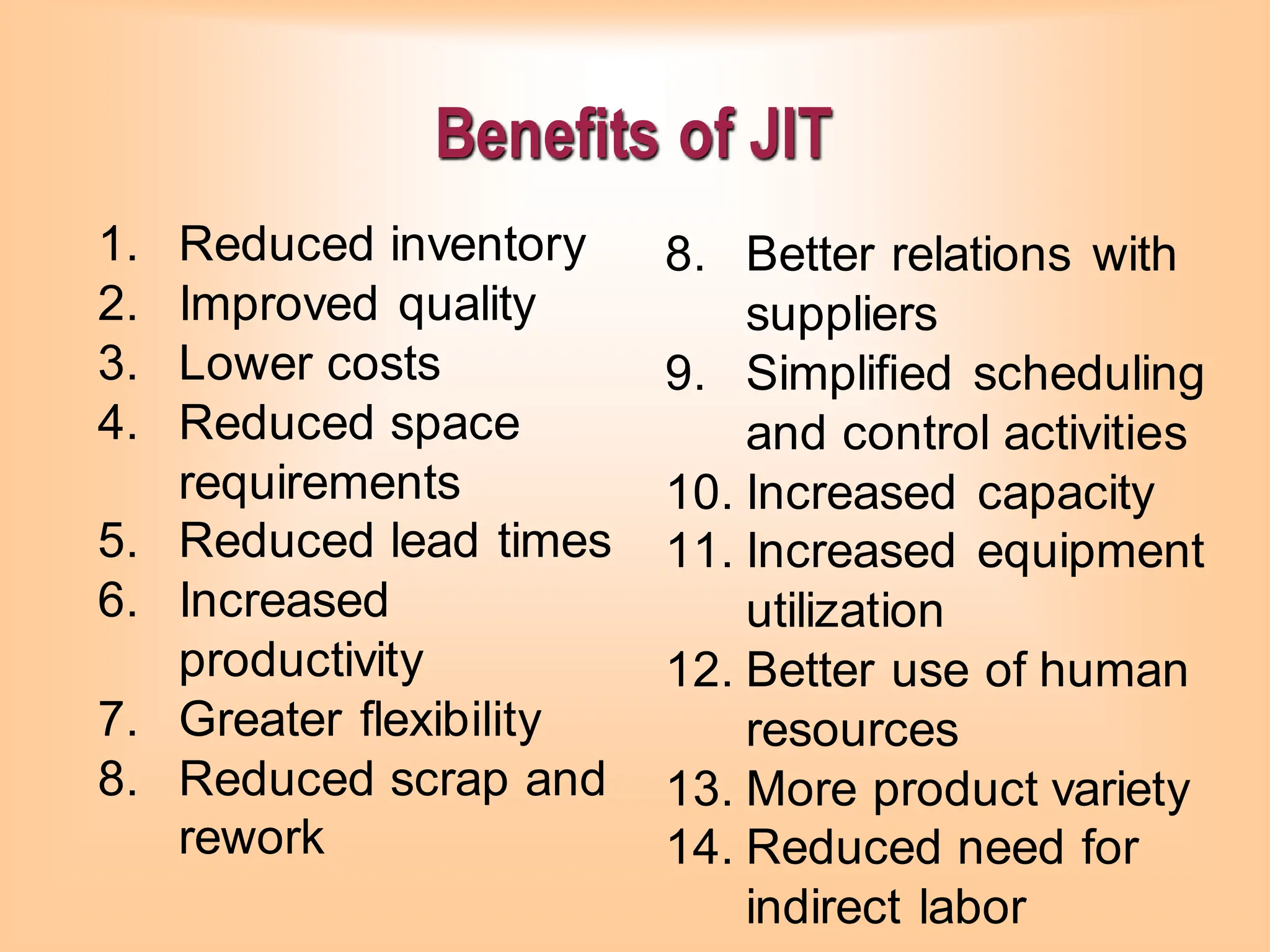

Just-in-time (JIT) is a management philosophy aimed at eliminating waste by ensuring that materials and services are produced and delivered as needed, thereby achieving streamlined production with minimal inventory. It relies on continuous improvement, employee involvement, and a flexible system to address bottlenecks and quality issues. The goals of JIT include a balanced production flow, reduced lead times, and improved supplier relationships, with emphasis on small lot sizes and effective communication through systems like Kanban.