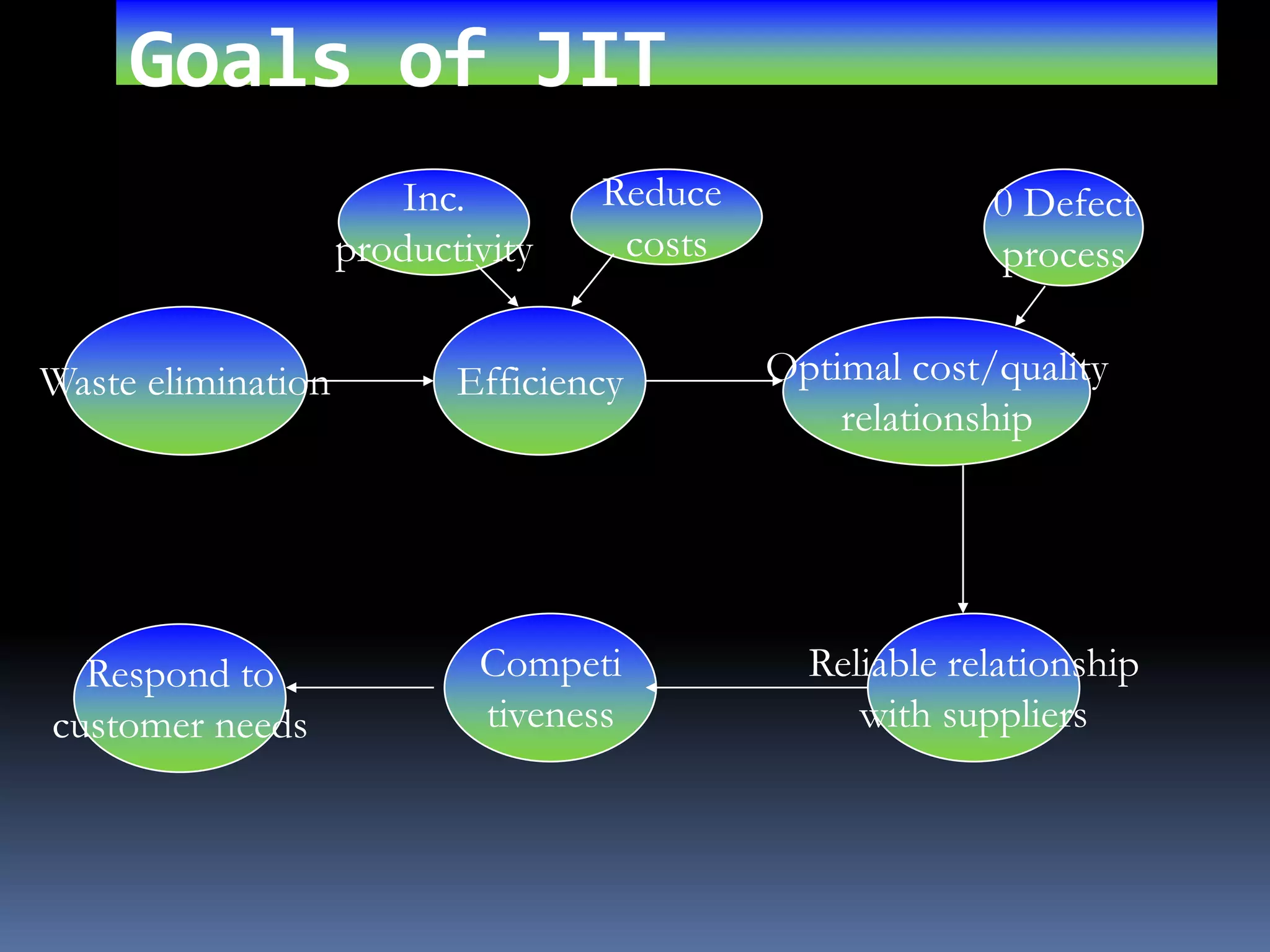

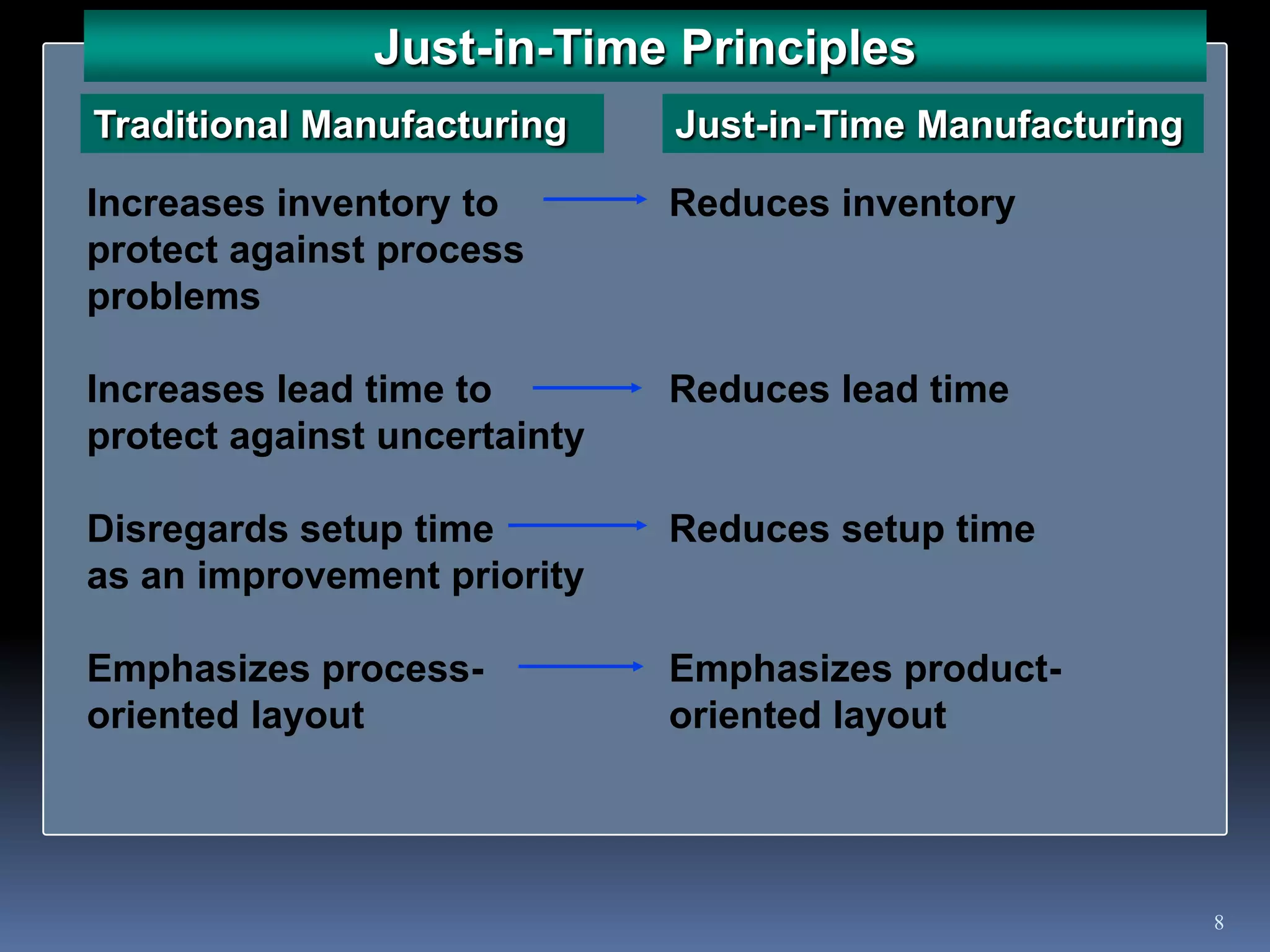

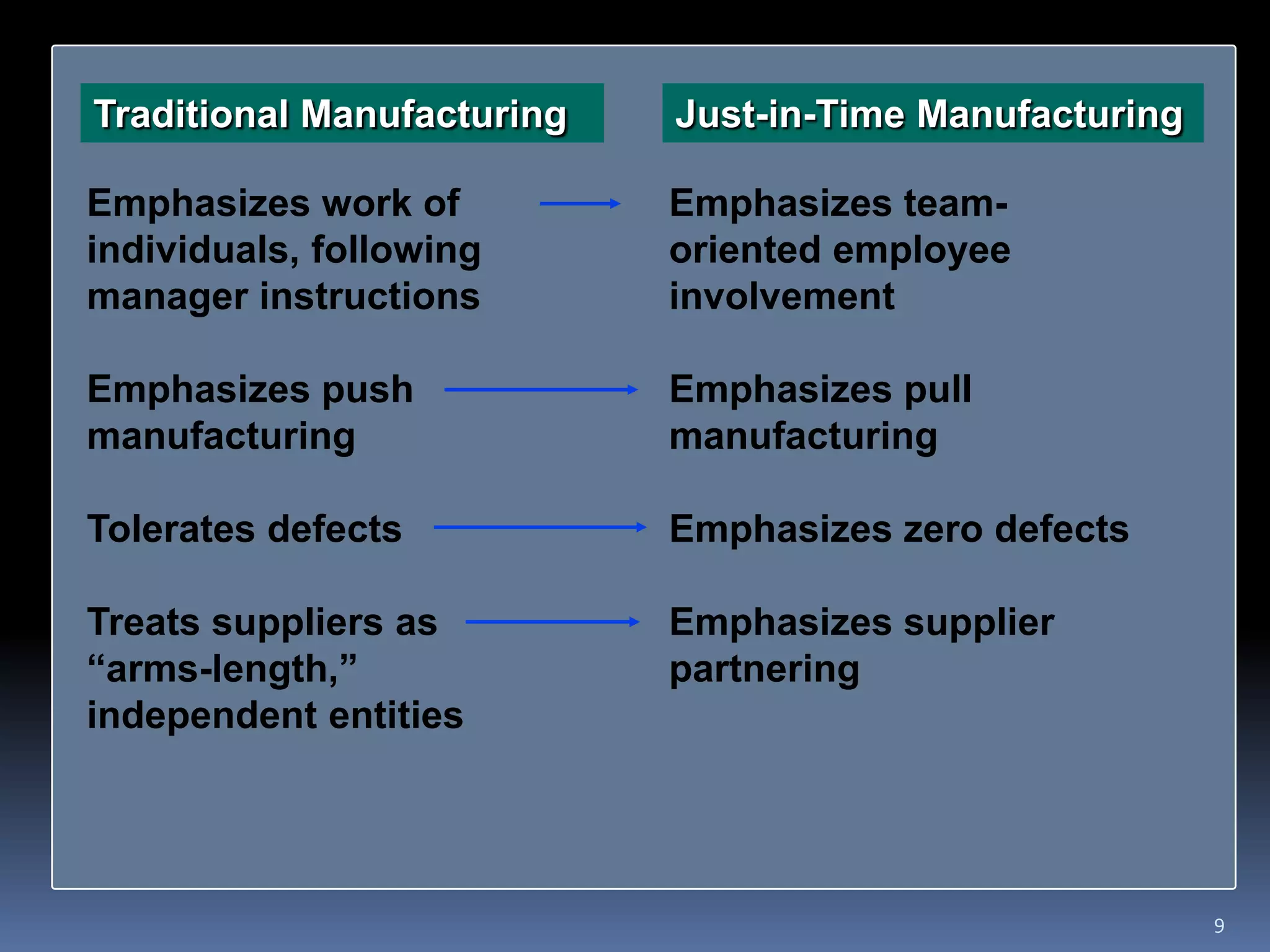

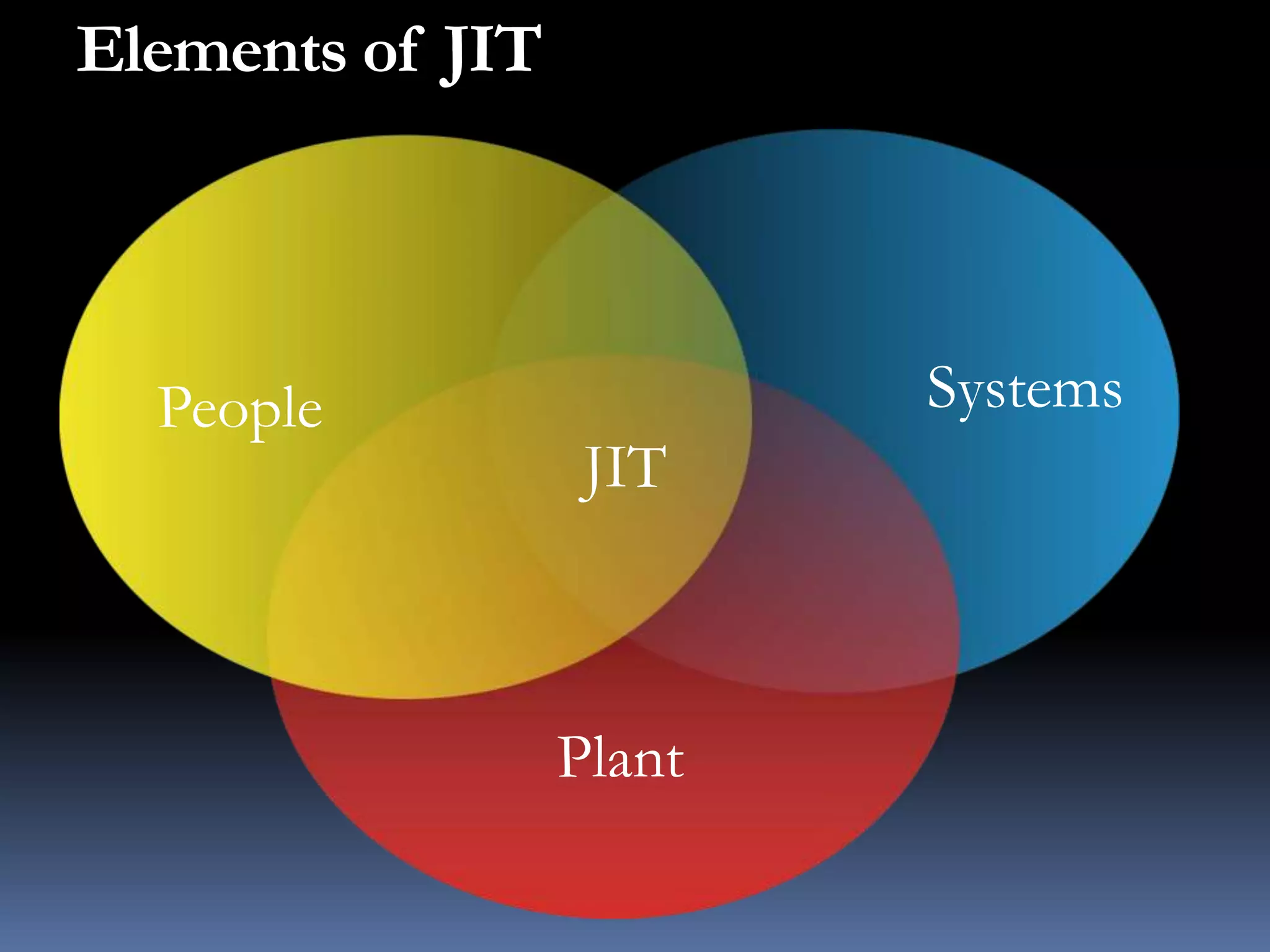

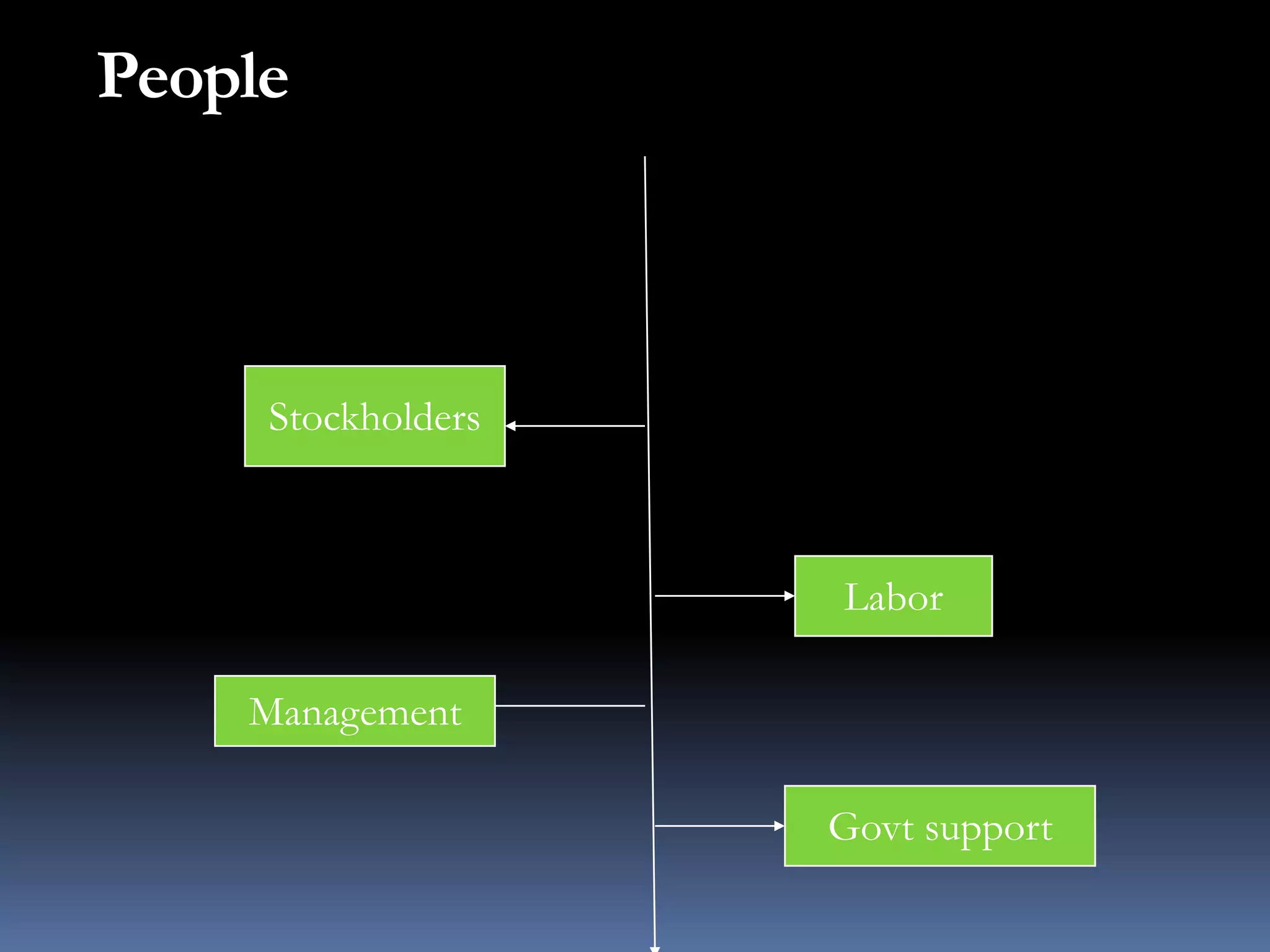

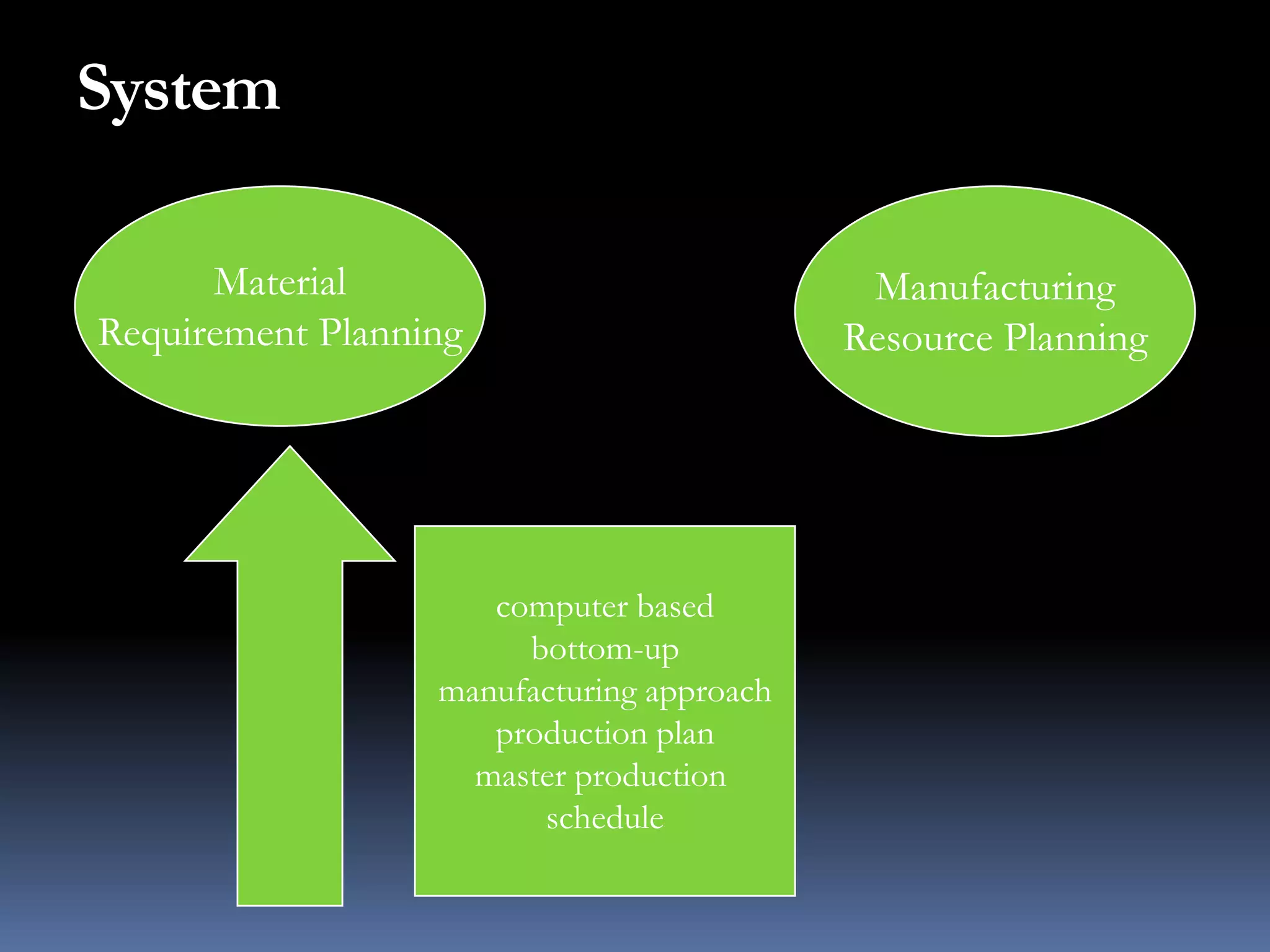

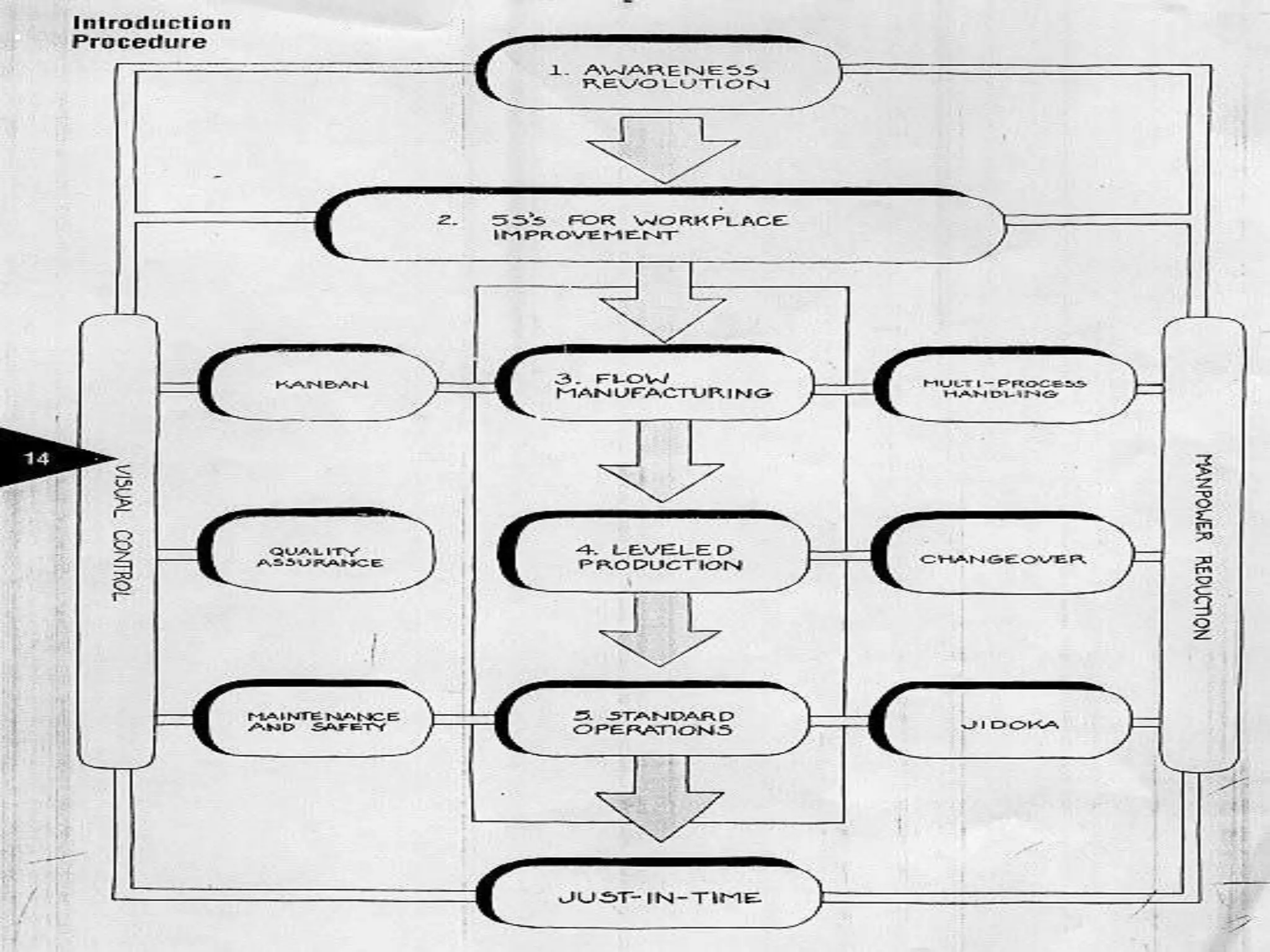

Just-In-Time (JIT) is a Japanese manufacturing philosophy developed in the 1970s that was first adopted by Toyota. The main goal of JIT is to meet consumer demands by eliminating waste in the production system. It aims to reduce inventory and lead times by producing only what is needed for smooth, efficient production. JIT requires extensive commitment and changes such as standardization, multi-skilled workers, pull-based production, and close supplier relationships to be successful.