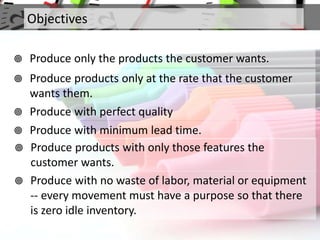

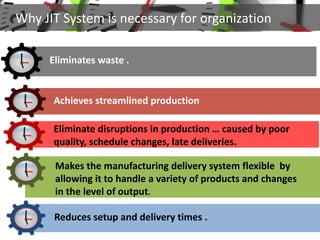

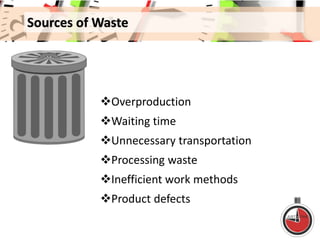

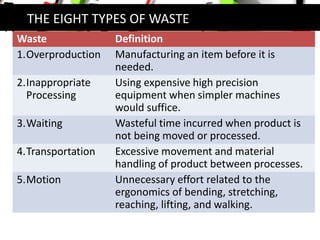

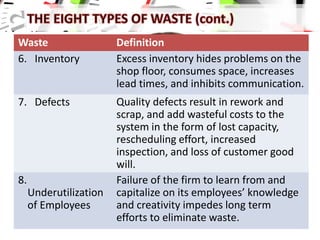

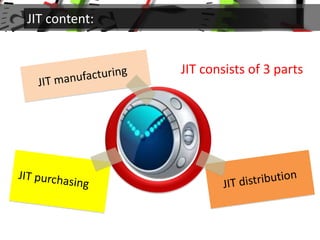

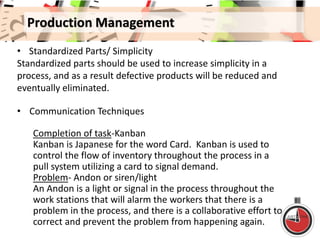

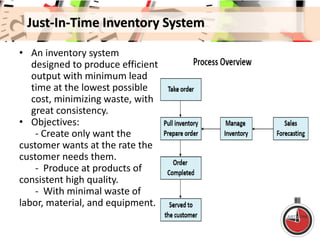

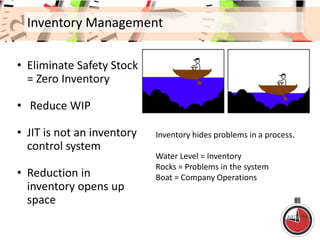

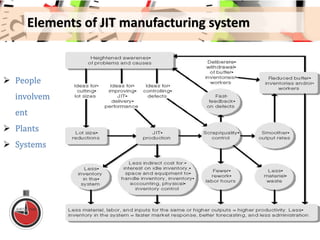

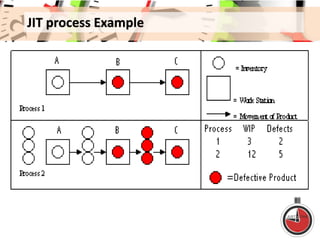

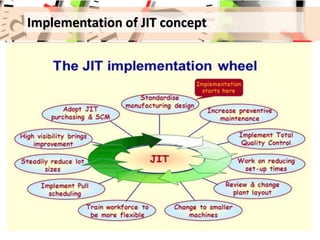

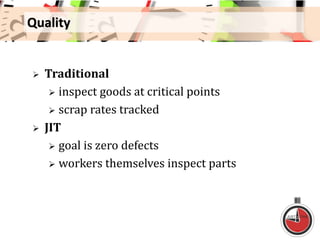

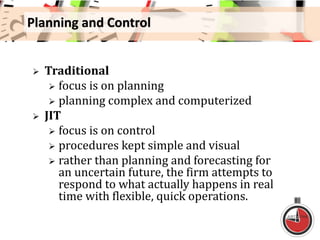

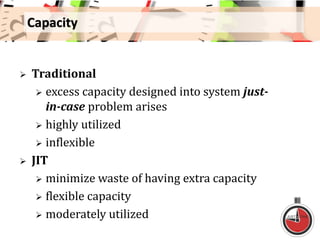

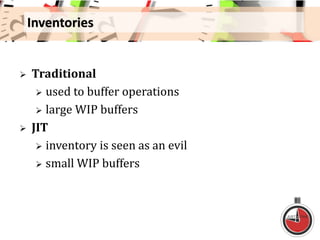

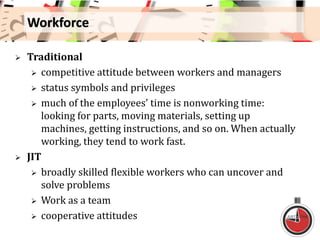

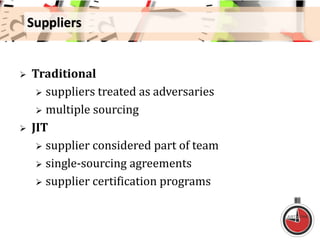

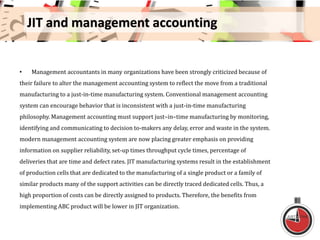

This document provides an overview of just-in-time (JIT) manufacturing. It discusses the history and objectives of JIT, the eight types of waste in manufacturing, and the three parts of JIT - purchasing, manufacturing, and quality management. Key aspects of JIT covered include production management, supplier management, inventory management, and human resource management. The document also compares traditional manufacturing systems to JIT systems and discusses how management accounting must adapt to support JIT goals.