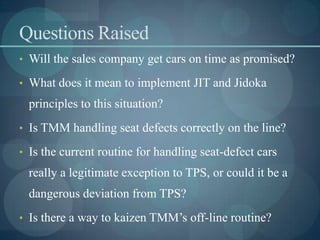

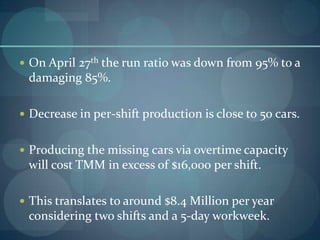

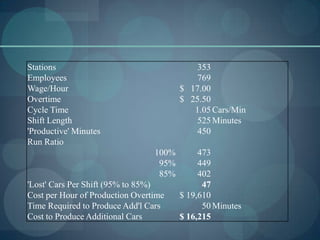

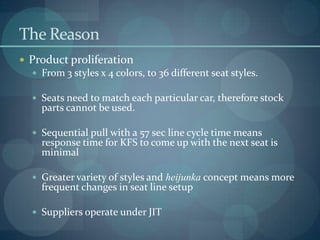

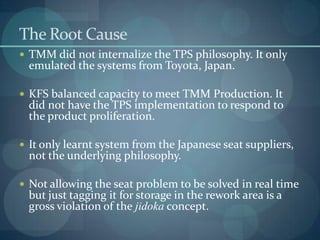

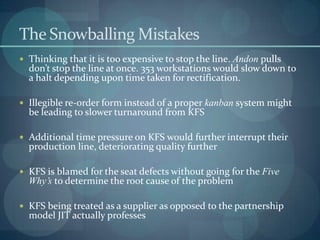

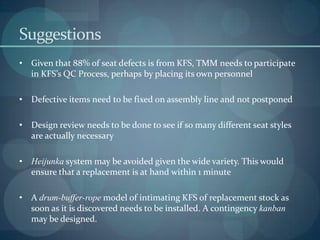

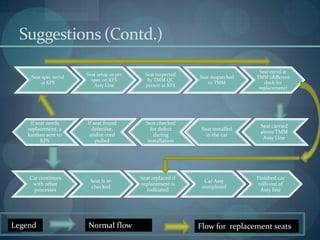

Toyota Motor Manufacturing (TMM) is facing increasing problems with defective seats from its single supplier Kentucky Framed Seat (KFS). The defects have reduced TMM's production run ratio from 95% to 85%, costing over $8 million per year to make up the lost production. The issues are caused by a lack of TPS implementation in both TMM and KFS operations, as well as increased seat variety from product proliferation. Suggestions include having TMM personnel assist KFS with quality control, replacing defective seats on the line, reducing seat variety, and implementing drum-buffer-rope pull systems between the companies.