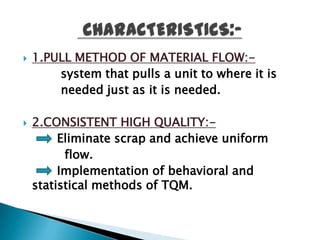

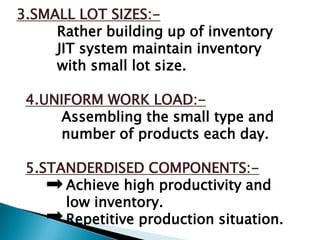

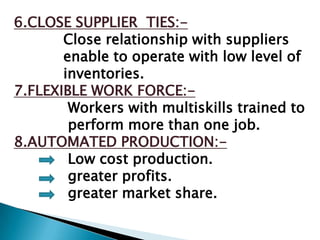

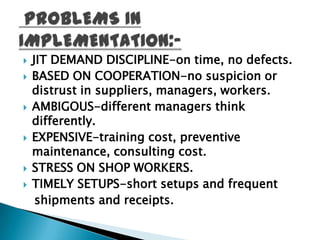

Toyota developed just-in-time (JIT) manufacturing in the 1970s-1980s to improve quality and reduce costs. JIT aims to eliminate waste by providing the right parts at the right time and place. It is a philosophy of continuous problem-solving that pulls supplies through production as needed. Key elements include acquiring inventory as needed, improving quality, reducing lead times, and daily revisions. JIT seeks to reduce waste and variability for low-cost, high-quality production through a pull-based system with small lot sizes and close supplier ties.