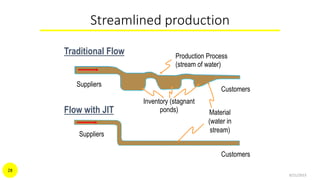

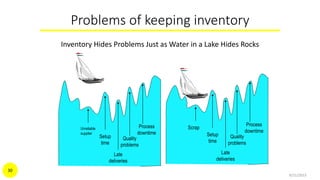

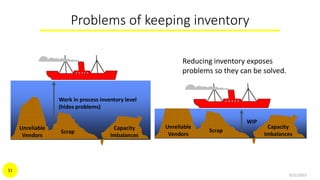

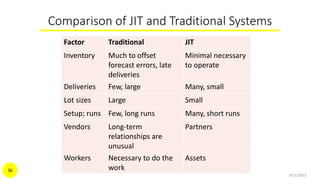

- Just-in-time (JIT) manufacturing was first developed by Toyota to reduce waste by supplying the right materials to production lines only when needed and in the minimum necessary amounts. It aims to eliminate overproduction and excess inventory that do not add value.

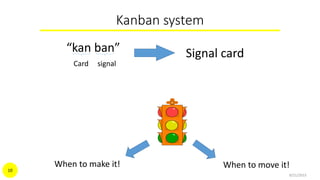

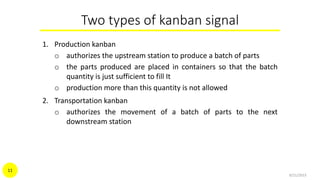

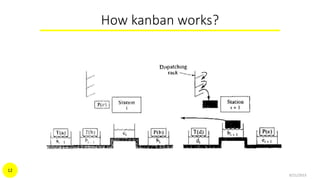

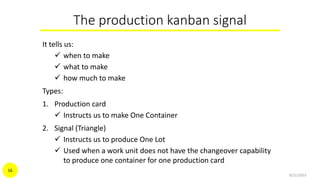

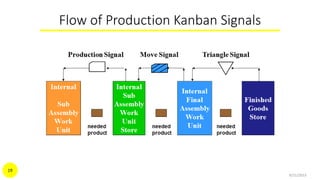

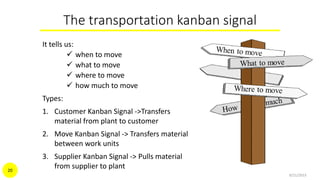

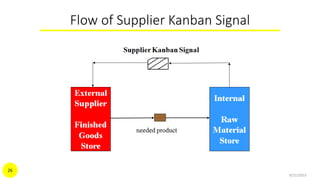

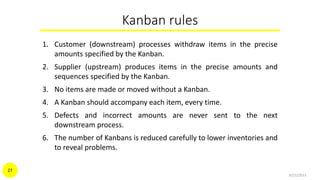

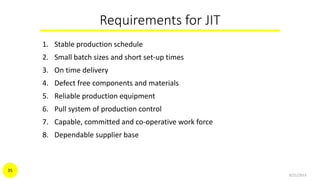

- Key aspects of JIT include a pull-based production system controlled through kanban signals, small lot sizes, low setup times, continuous flow, and close partnerships with suppliers. Implementing JIT exposes problems in production so they can be addressed, improving quality over time. It requires stable production schedules and reliable equipment and processes.