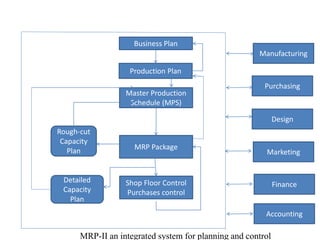

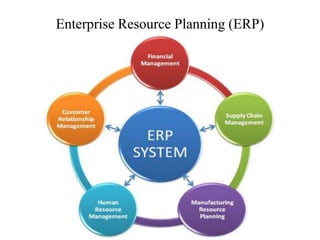

MRP-II is an integrated information system that coordinates all aspects of a business, not just manufacturing. It synchronizes activities like sales, purchasing, design, manufacturing, finance, and engineering. ERP builds on MRP-II by integrating an entire enterprise from suppliers to customers, covering logistics, financials, and human resources. This enables increased productivity through cost reductions. ERP functions by integrating information across departments so any action, like processing an order, is carried out instantly based on factors like inventory levels and credit limits.