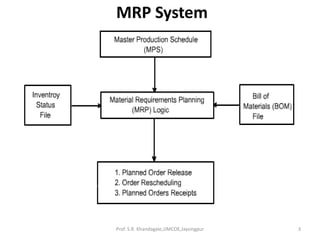

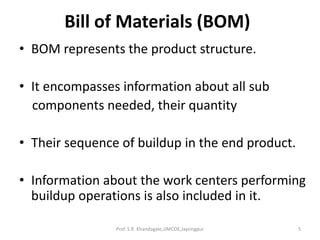

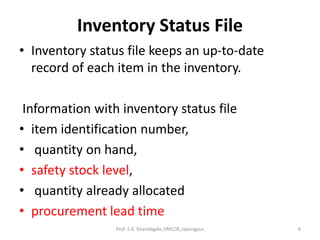

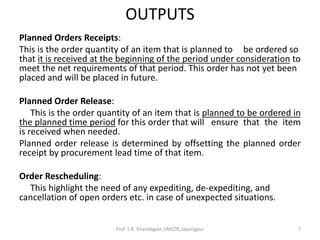

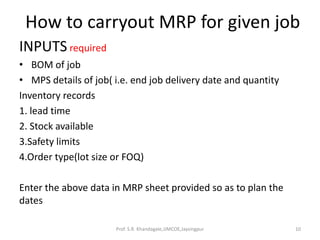

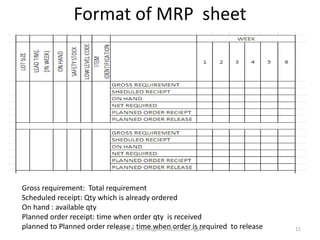

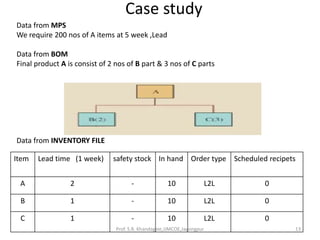

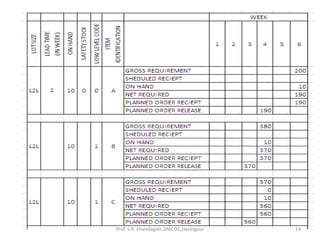

This document discusses Material Requirements Planning (MRP), including its objectives, components, and benefits. MRP is a system used for planning the quantities and timing of materials needed to meet production schedules. It aims to reduce inventory costs, meet delivery schedules, and improve performance. Key elements of MRP include the master production schedule, bill of materials, inventory status file, planned order receipts, and planned order releases. MRP is useful for companies with complex product structures and dependent demand. Benefits include reduced shortages, lower inventory levels, improved customer service, and increased plant efficiency.