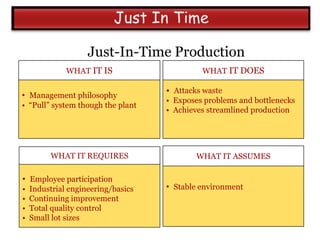

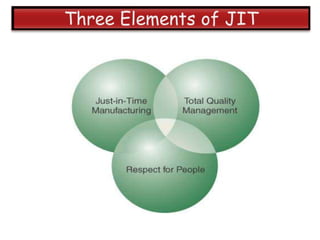

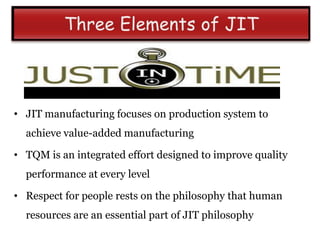

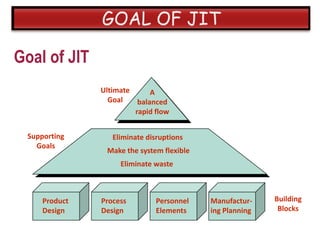

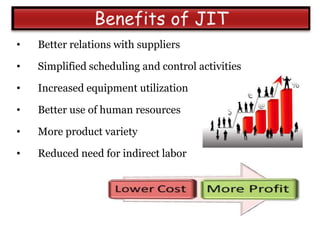

Just-in-time (JIT) production is a manufacturing philosophy aimed at eliminating waste by producing and delivering only what is needed, when it is needed, in the amount needed. Key aspects of JIT include reducing inventories, setup times, and travel distances while maximizing space usage. Implementing JIT requires employee participation, continuous improvement efforts, and stable supplier relationships. When done correctly, JIT can lower costs and lead times while improving quality, productivity, and resource utilization.