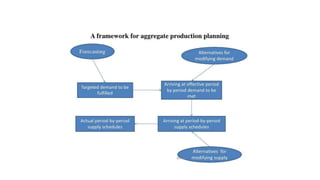

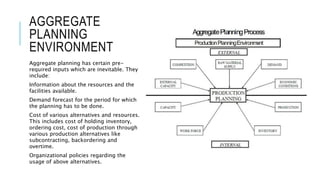

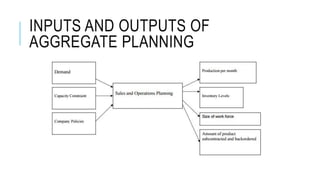

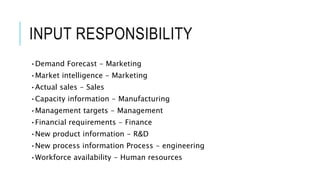

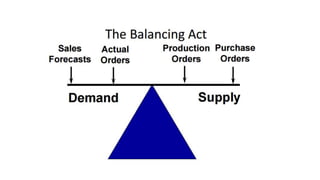

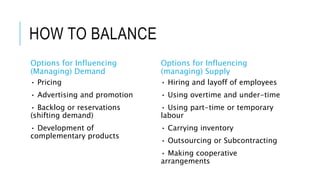

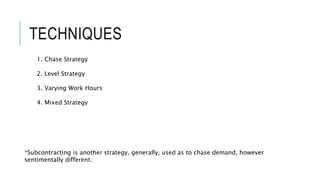

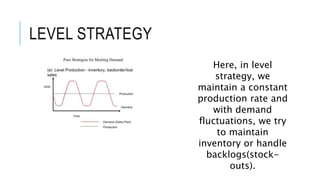

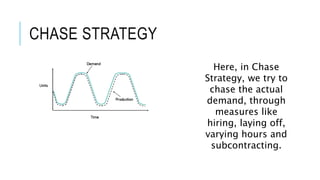

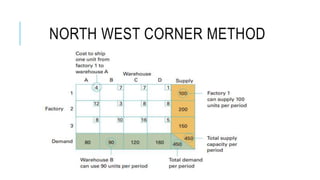

Aggregate production planning (APP) is an operational activity that creates a production plan for a 6 to 18 month period, focusing on matching supply and demand while minimizing operational costs. The process involves managing various inputs such as demand forecasts, capacity, and organizational policies to develop outputs like sales and production plans. Different planning strategies are utilized to handle fluctuations in demand and supply, including chase and level strategies, as well as the use of transportation models for efficient distribution.