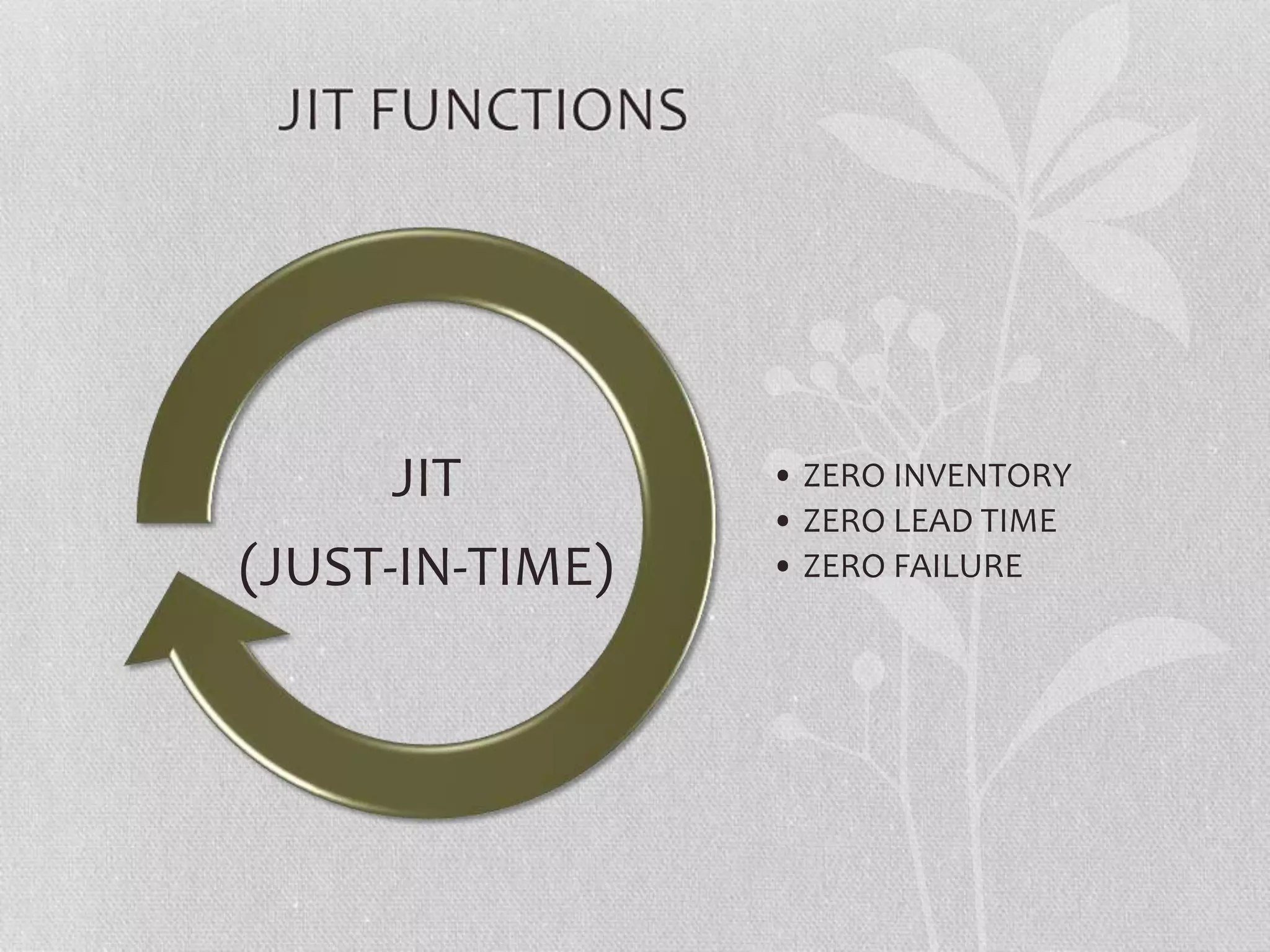

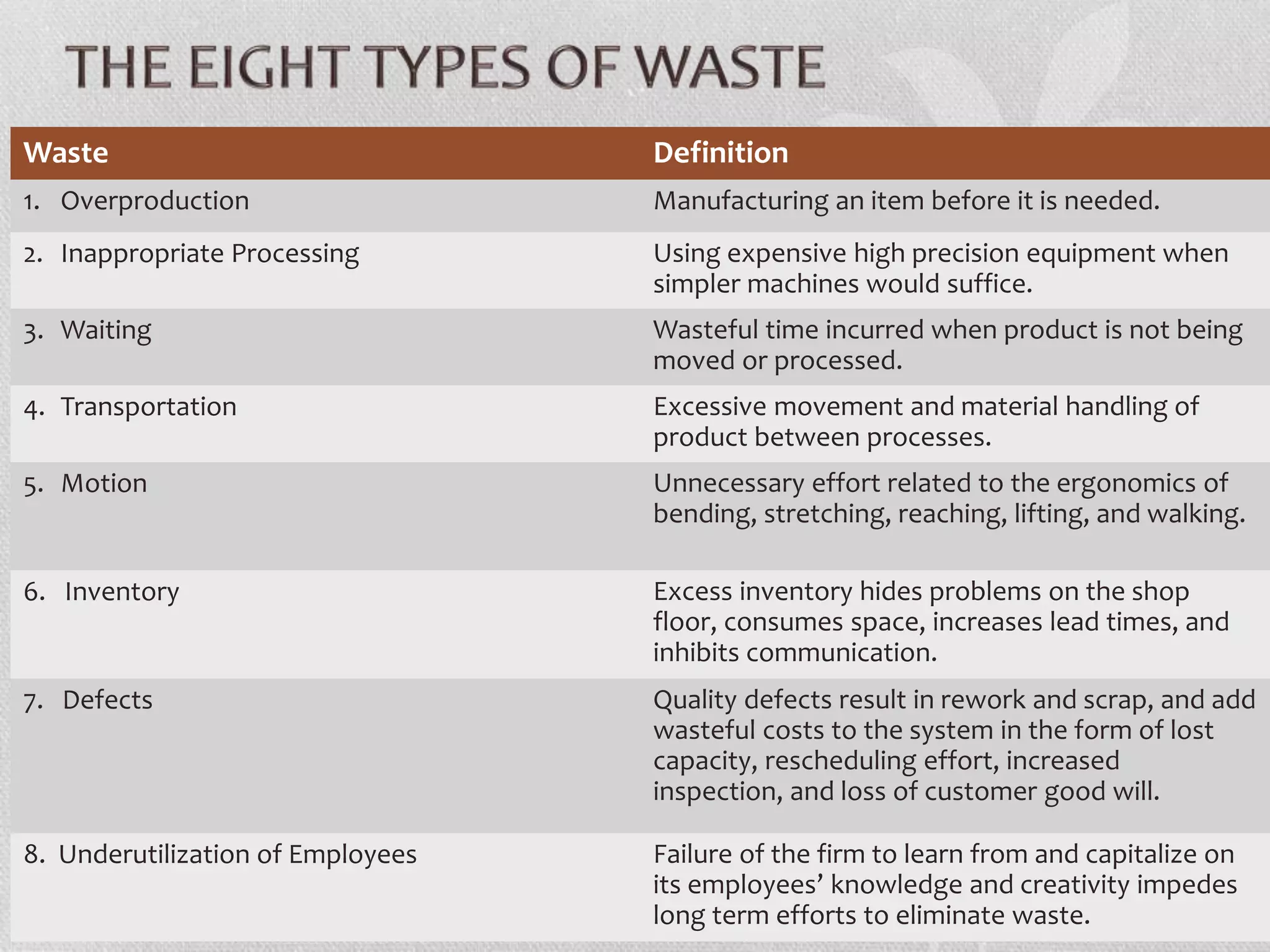

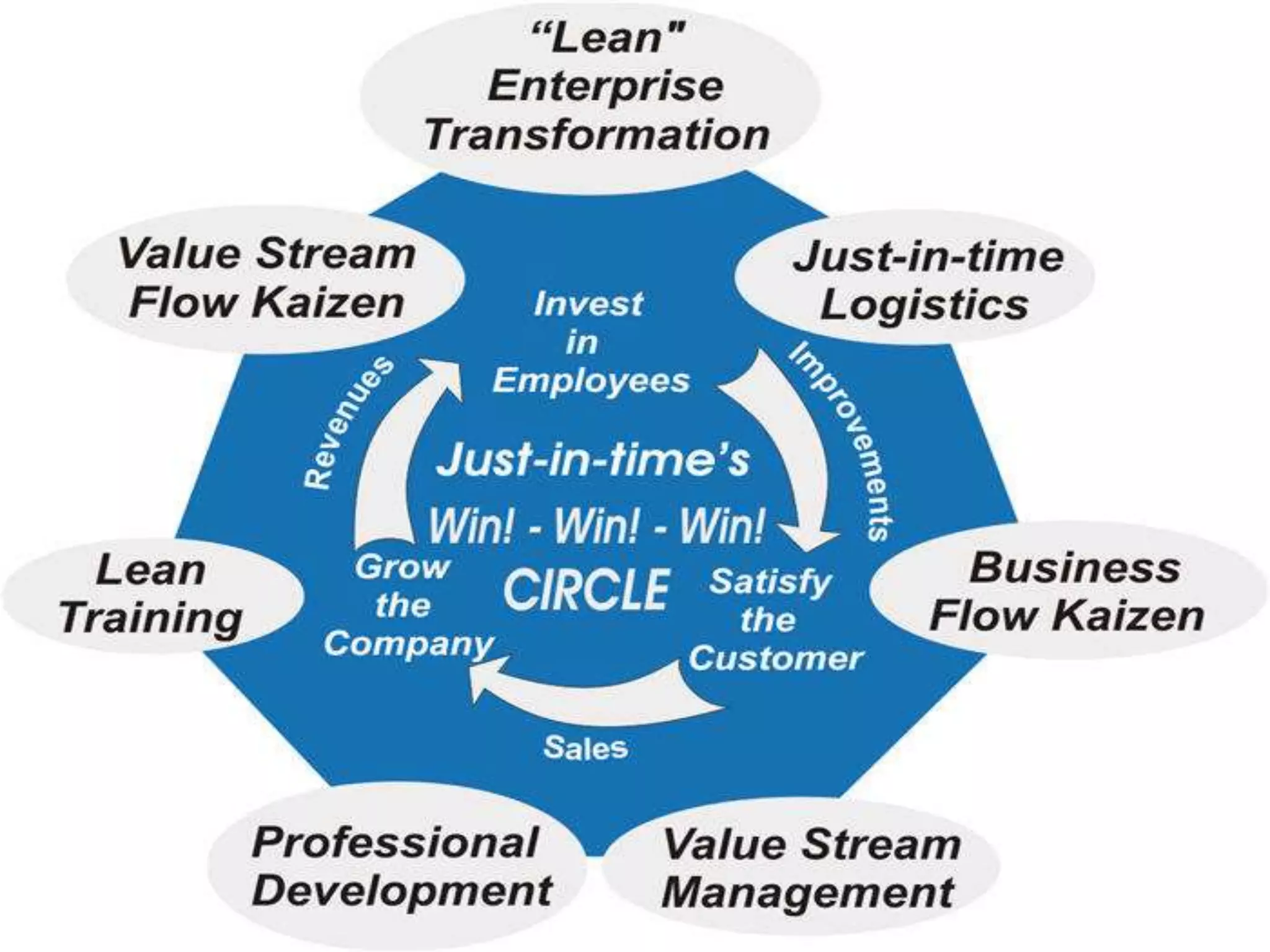

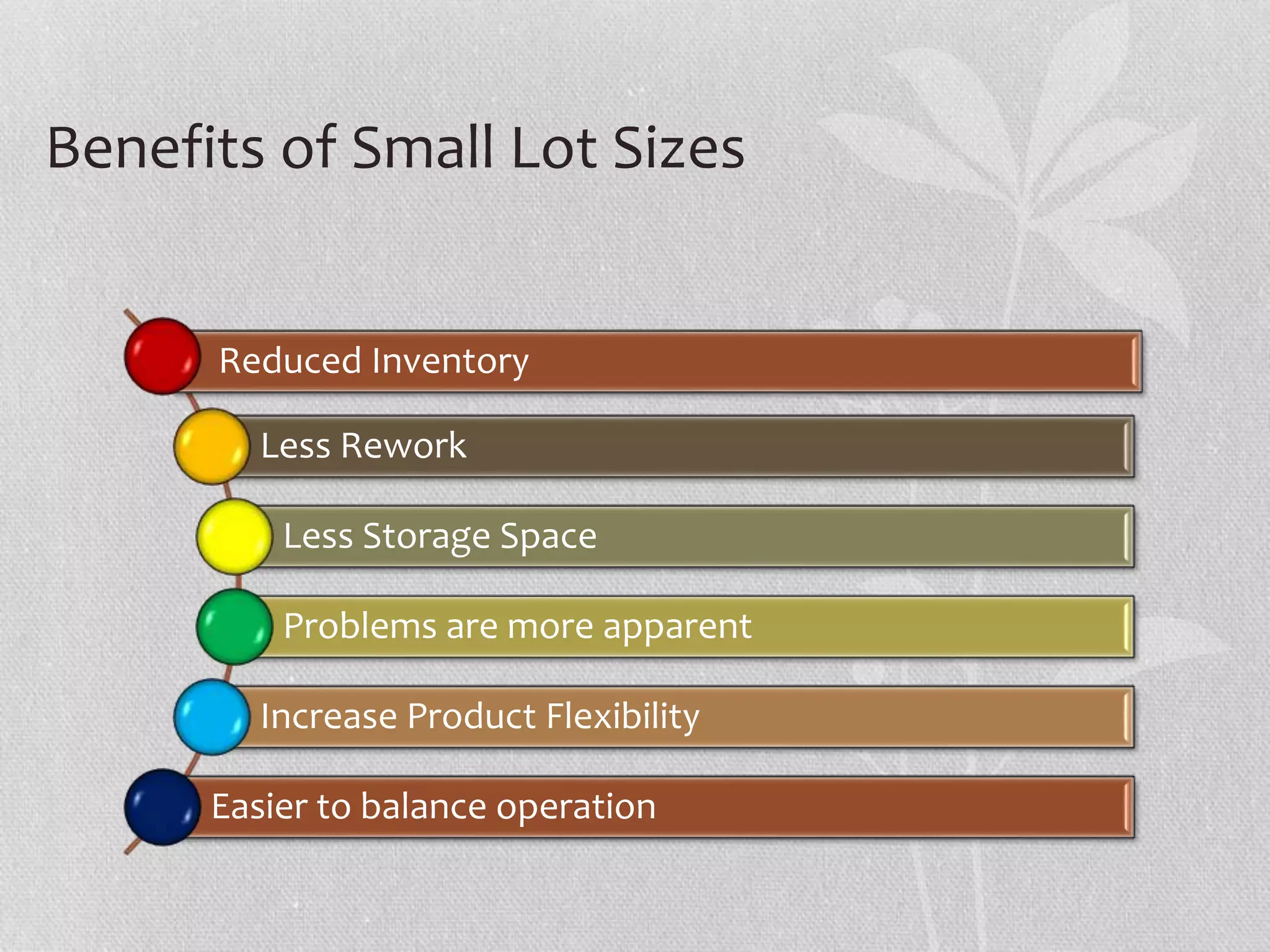

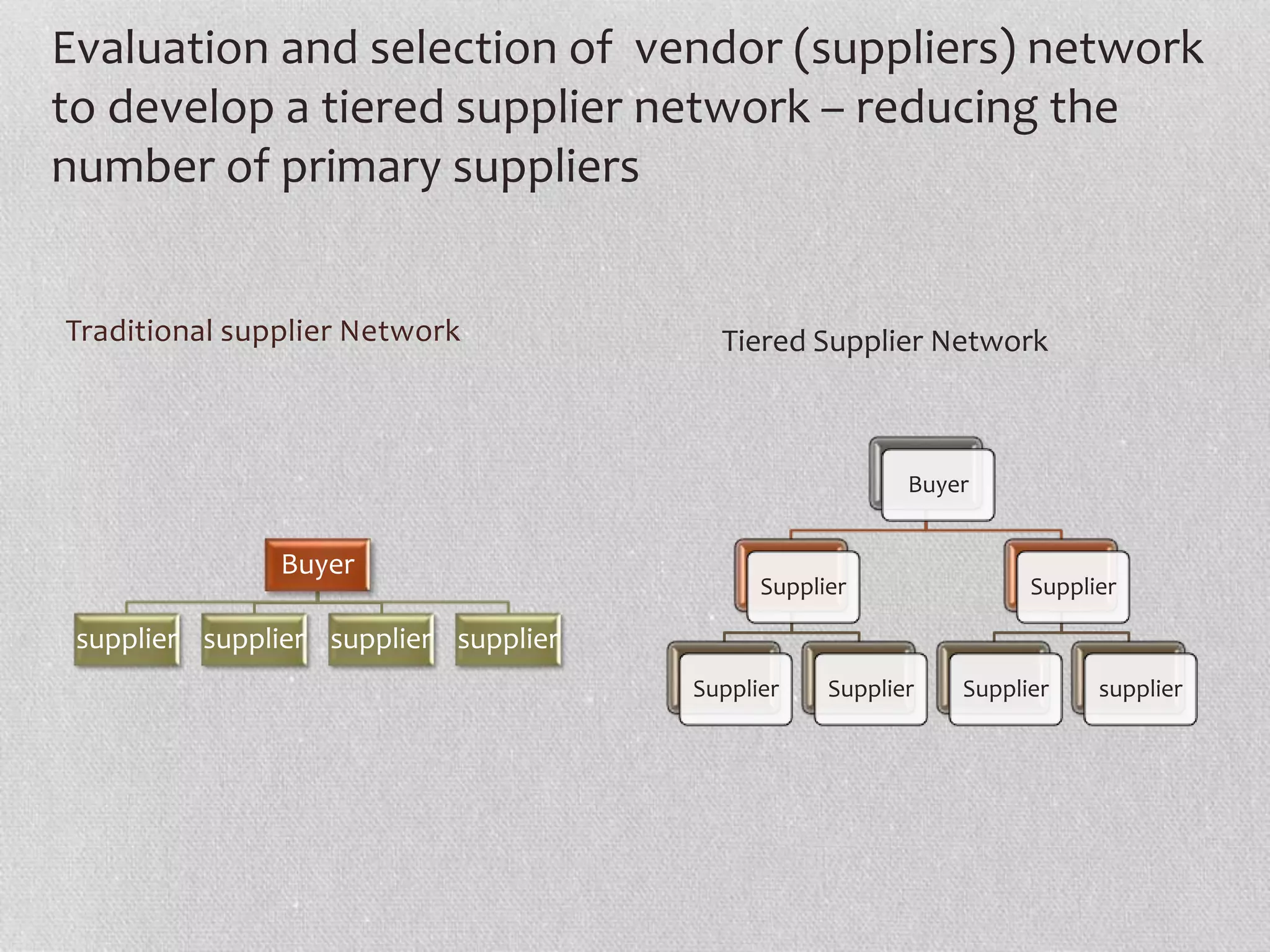

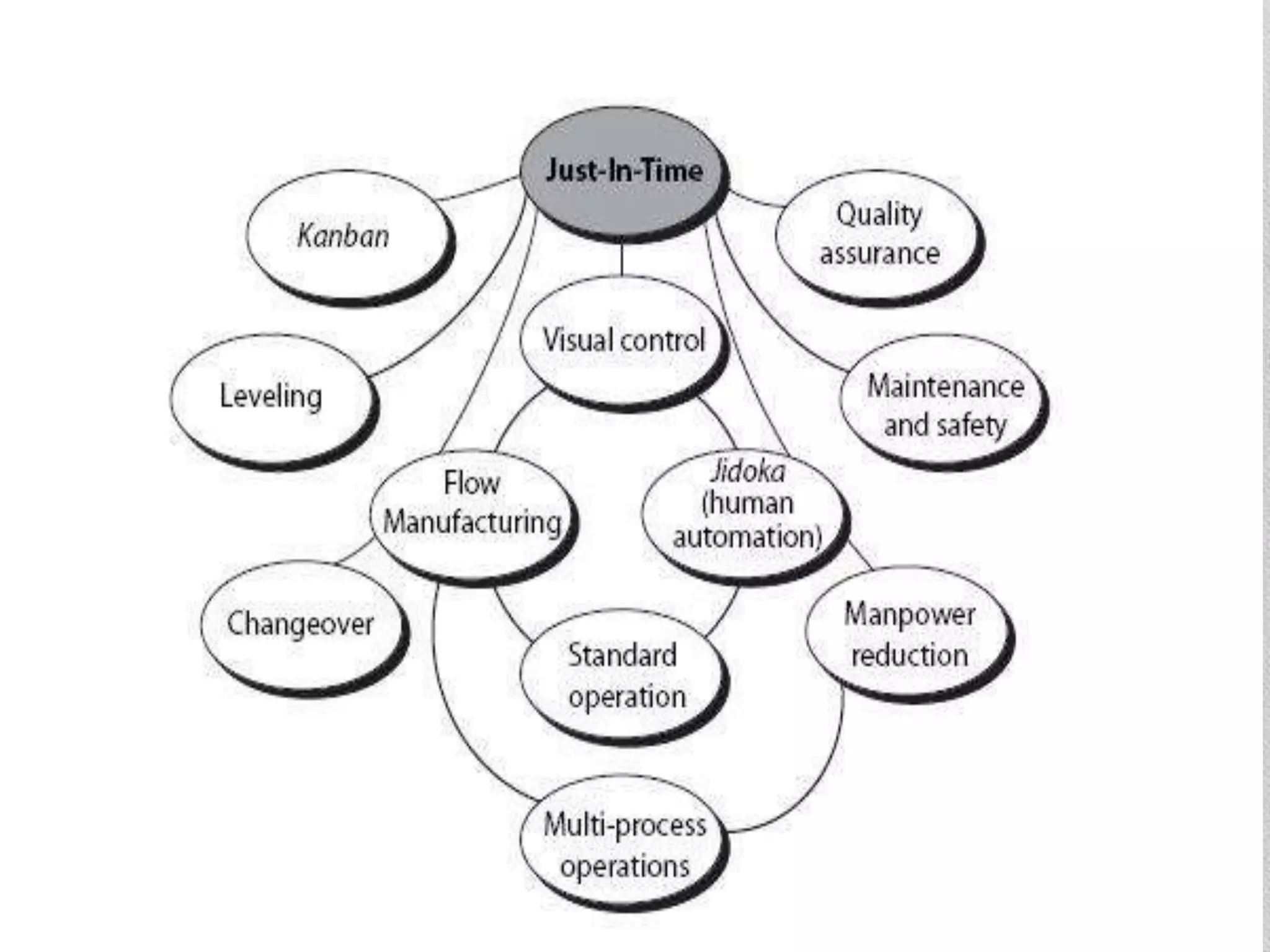

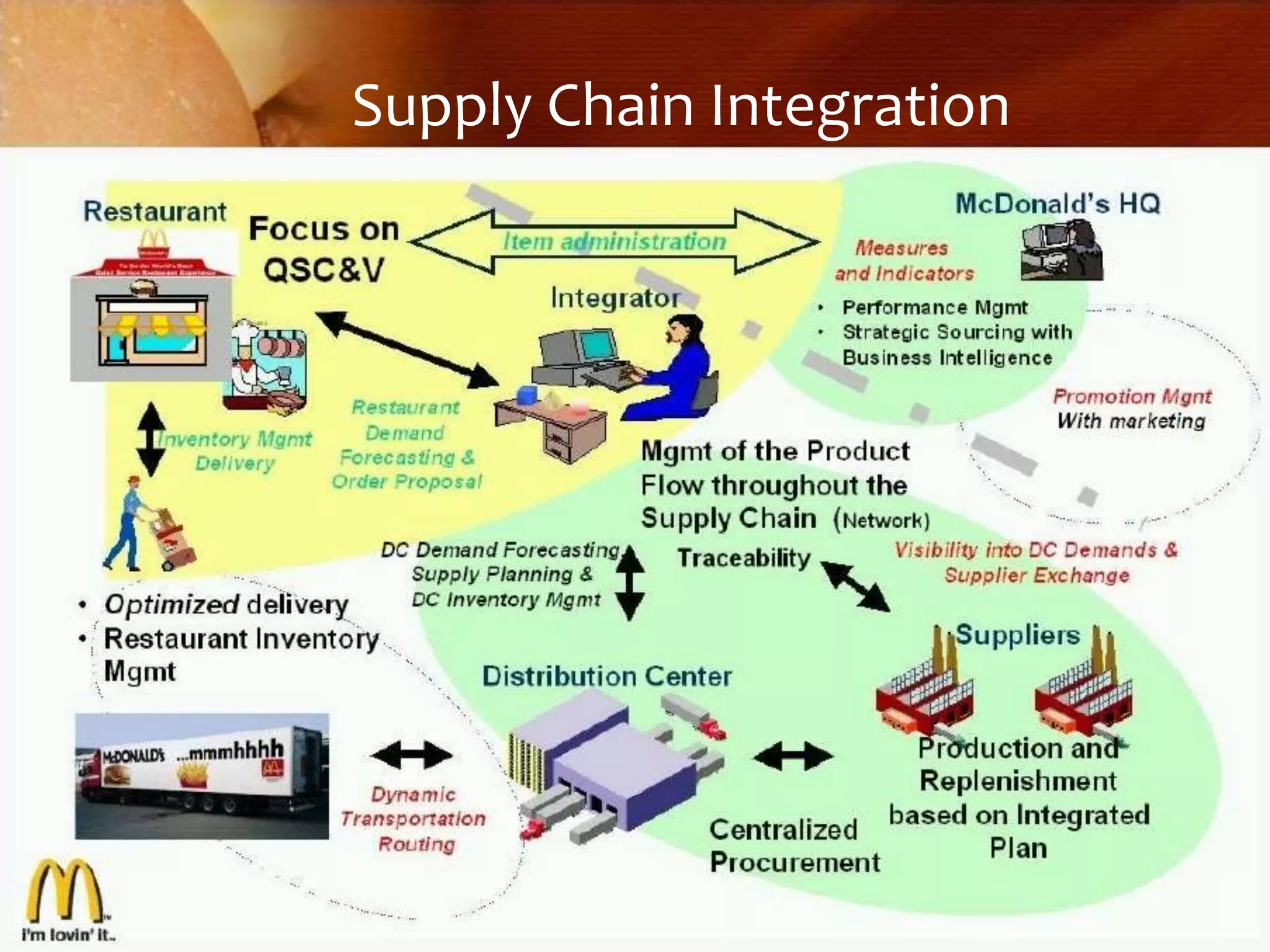

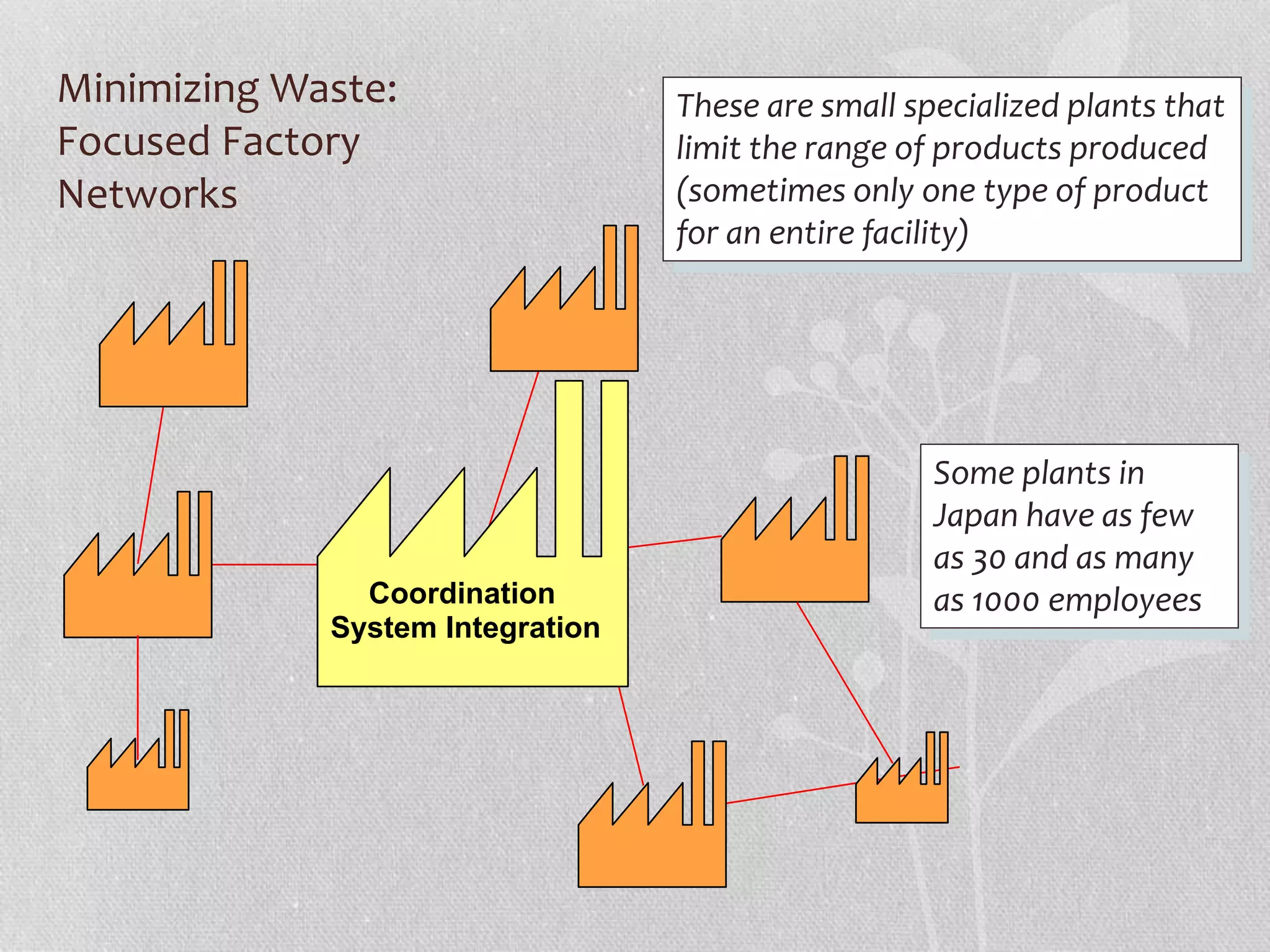

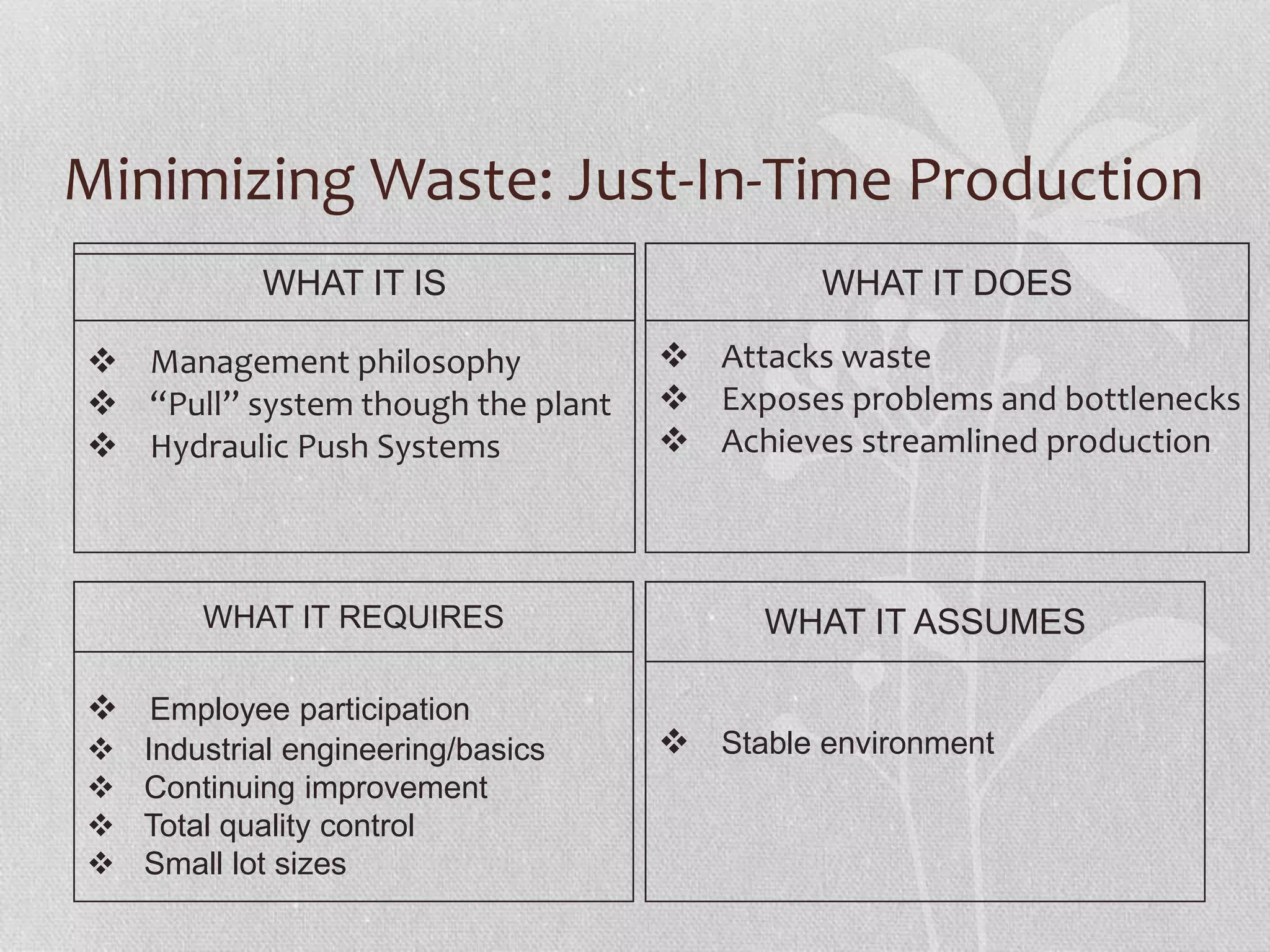

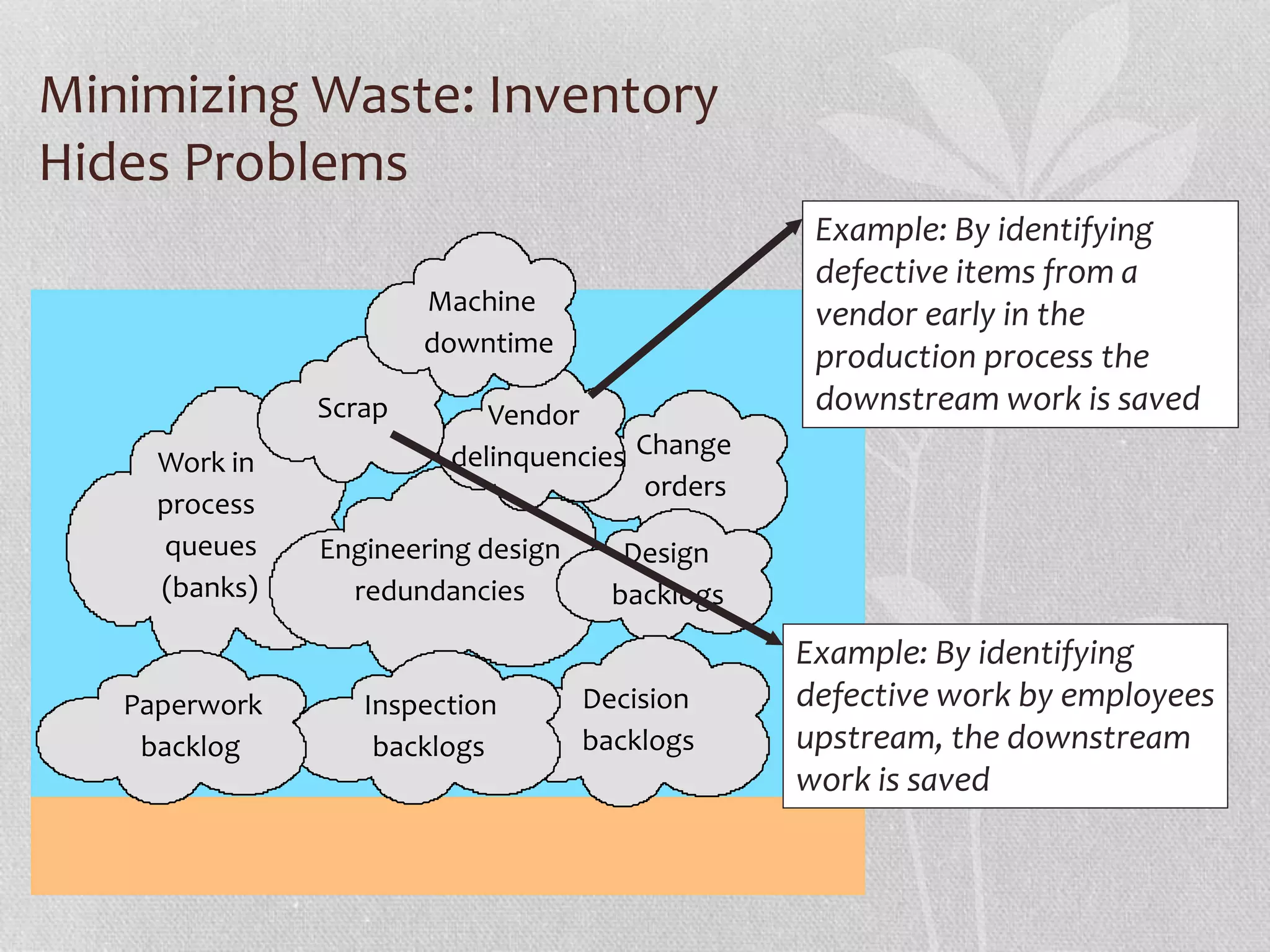

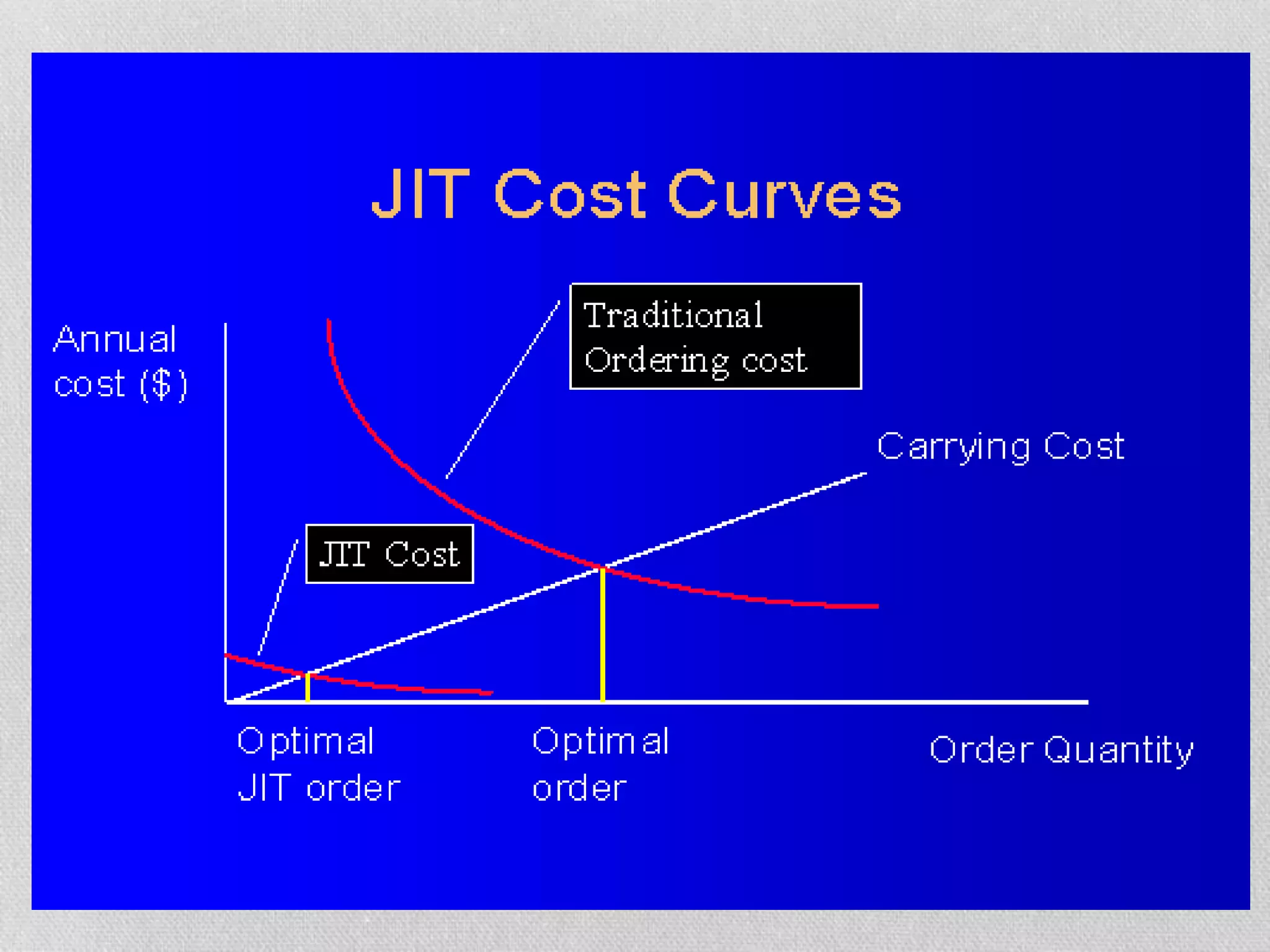

The document discusses the Just-in-Time (JIT) manufacturing philosophy, emphasizing its focus on waste elimination and continuous improvement. It outlines the benefits and challenges of implementing JIT, including improved quality, reduced inventory, and the necessity of management support and training. Additionally, the document highlights the historical development of JIT, particularly its origins in Japan and its application in companies like Toyota and McDonald's.