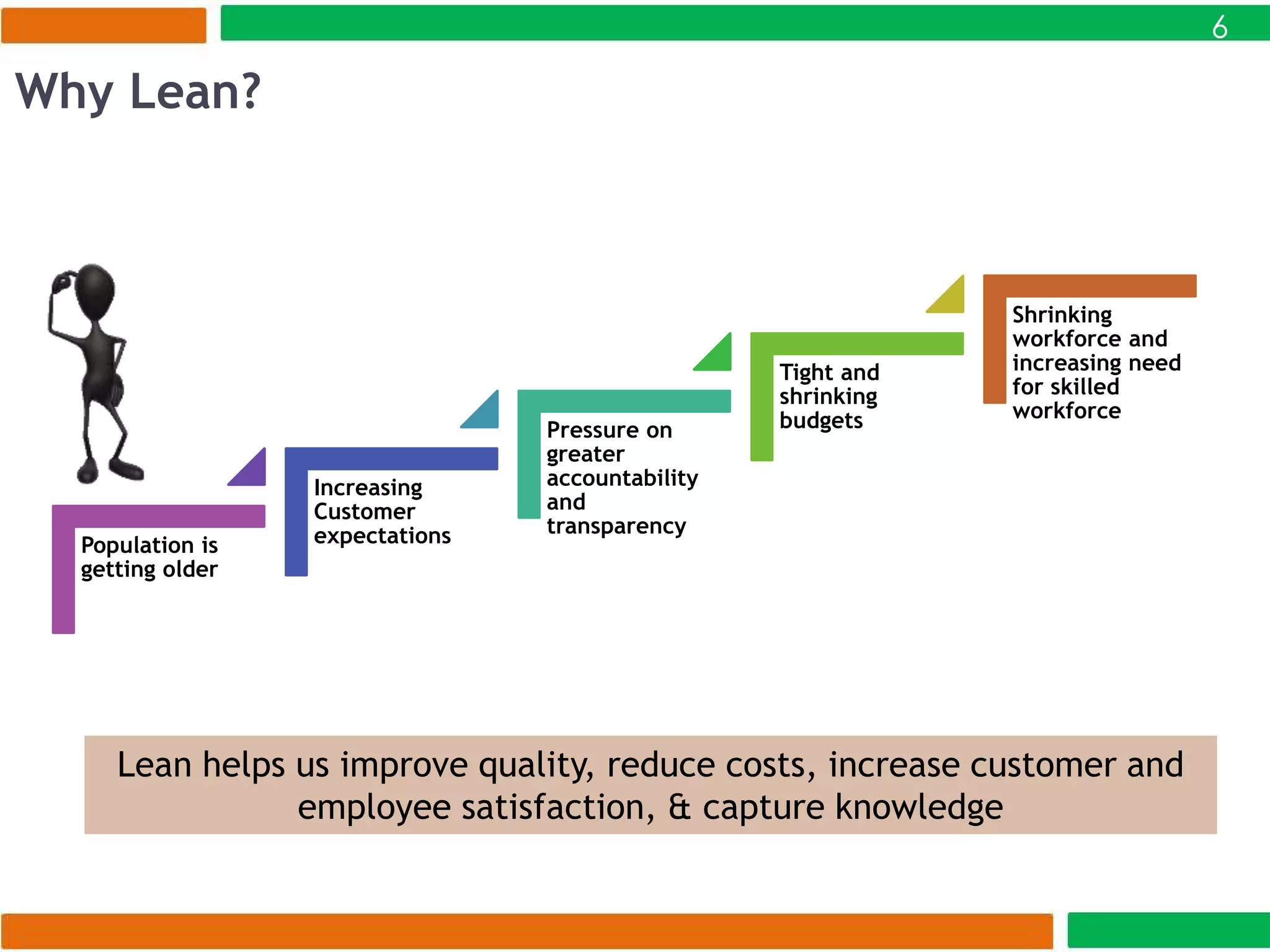

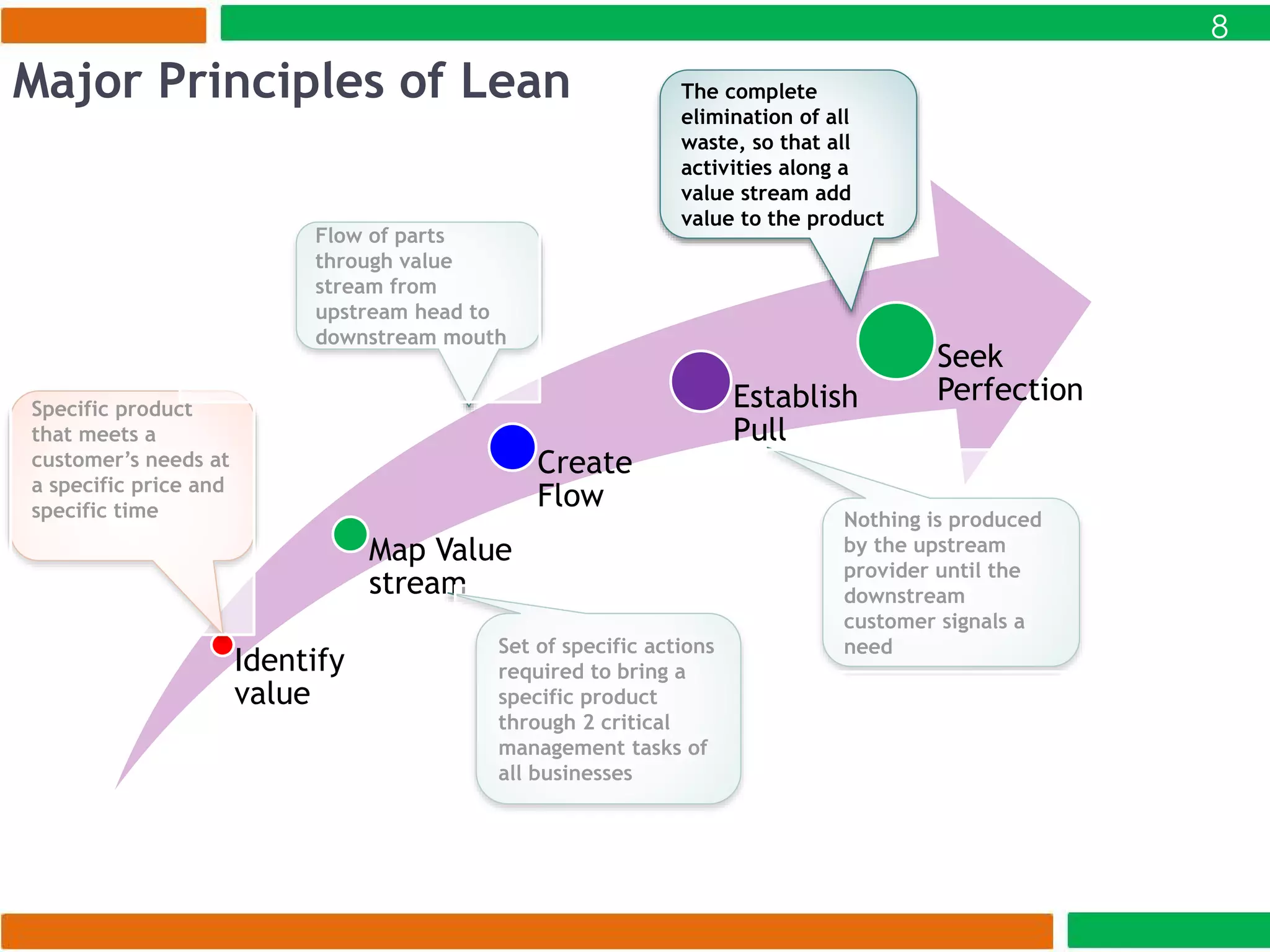

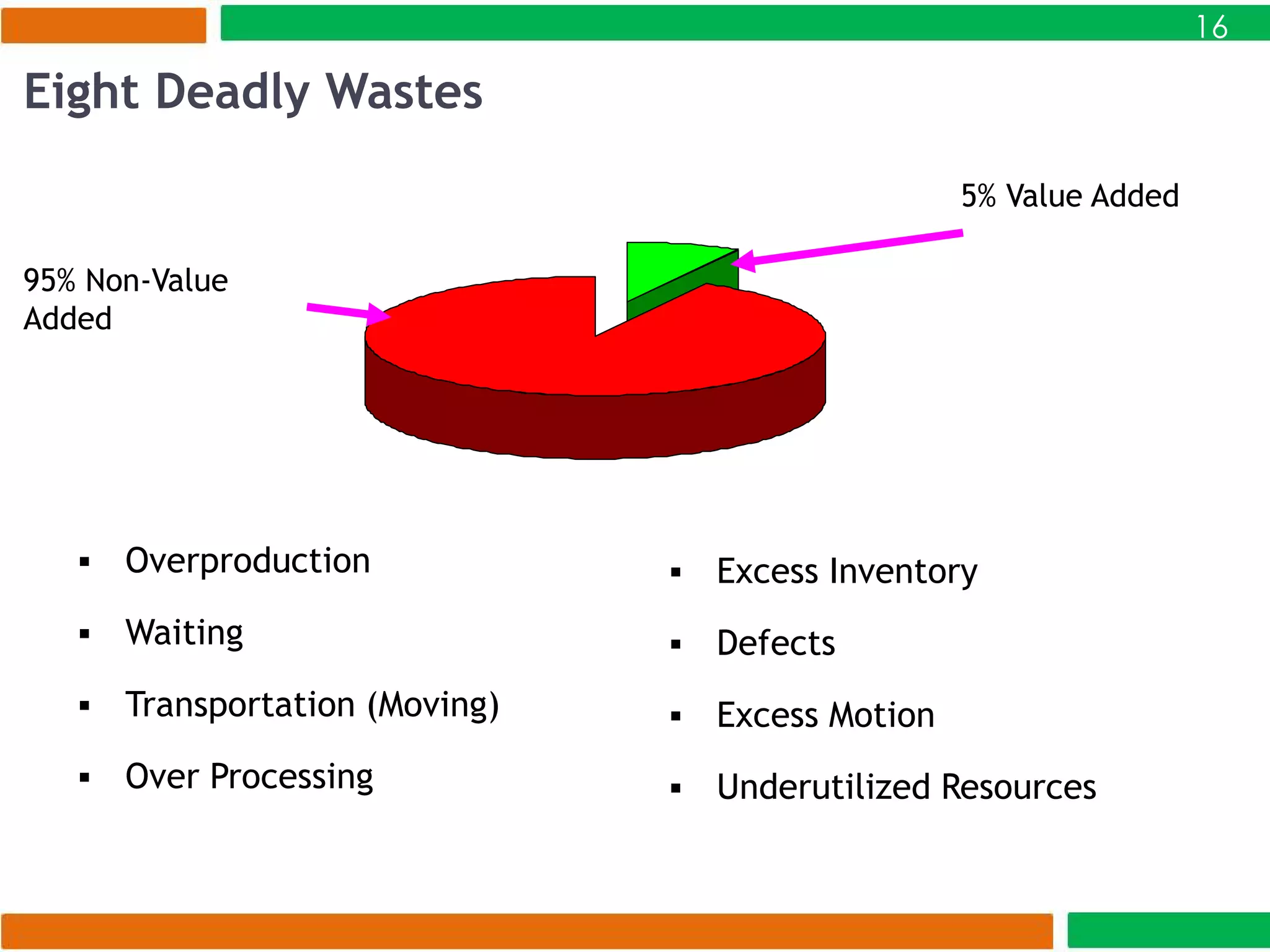

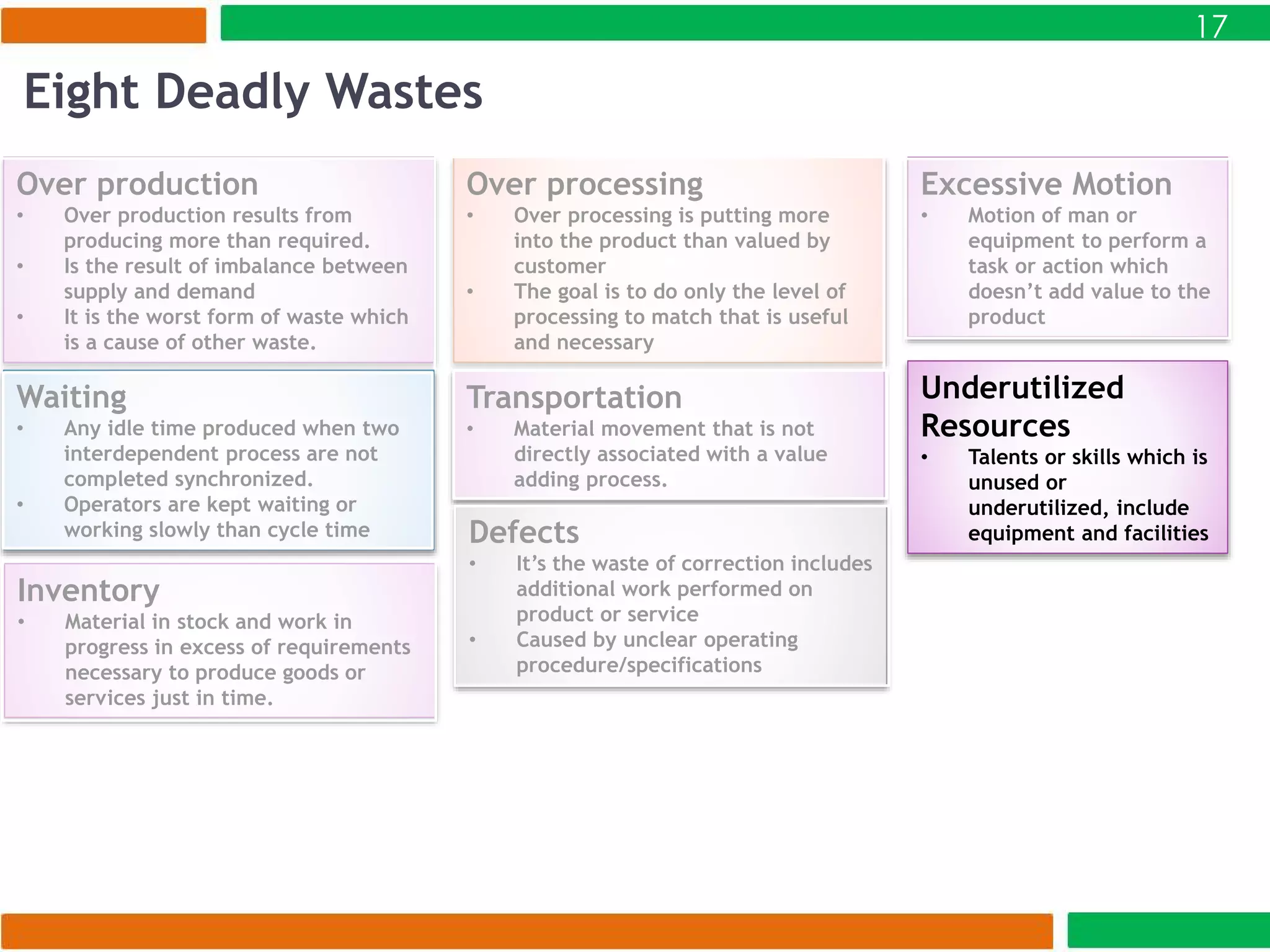

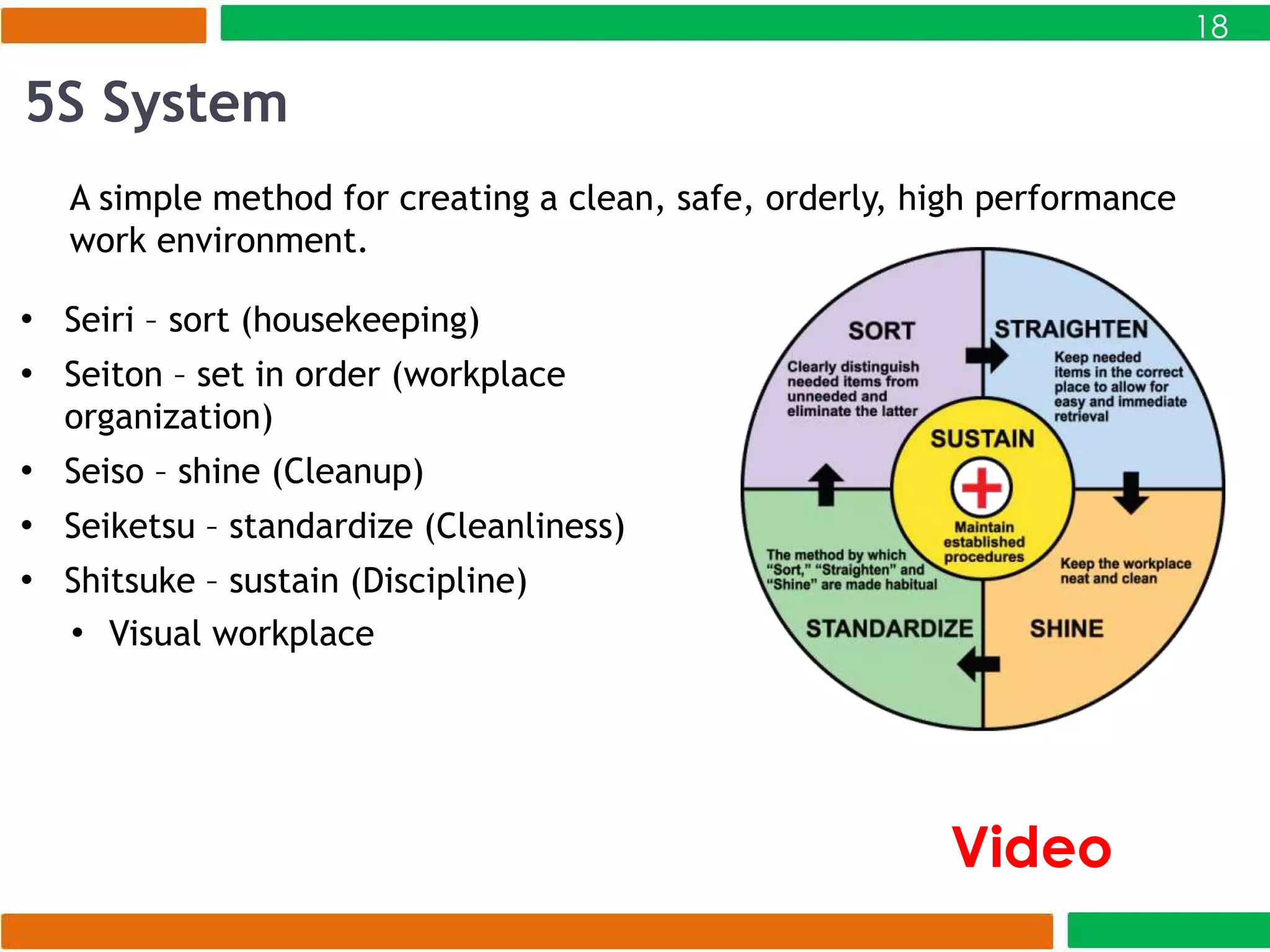

This document provides an introduction to Lean principles, methodology, tools and terminology. It discusses what Lean is, its history and key principles. Lean is a way to pursue value and eliminate waste from daily processes. This results in lower costs, reduced cycle times, fewer defects, improved customer satisfaction and employee morale. The document outlines various Lean concepts and tools, including the eight wastes, 5S, visual management, Kaizen (continuous improvement), standard work and mistake-proofing. It emphasizes identifying value, mapping value streams, establishing flow and pull, and seeking perfection through eliminating waste.