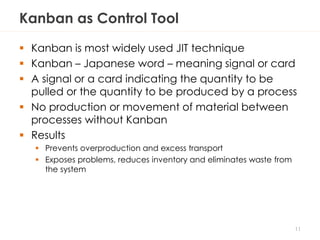

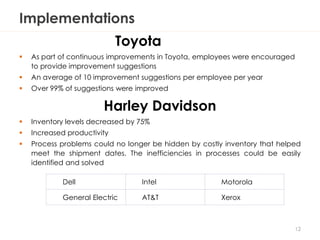

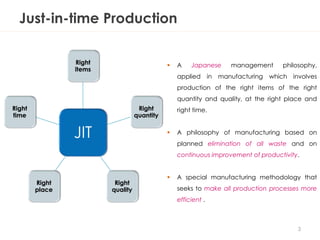

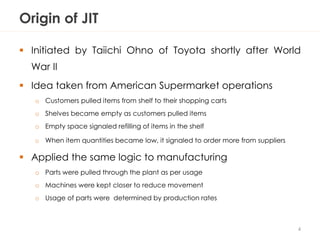

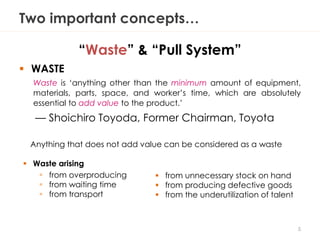

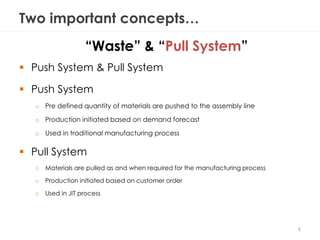

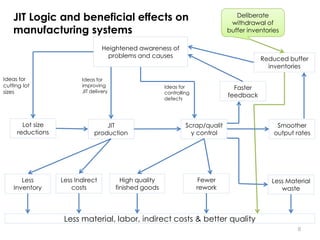

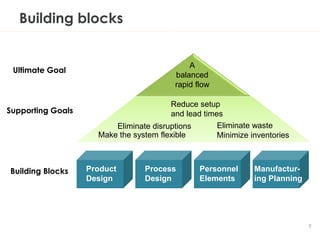

This document provides an overview of Just-in-Time (JIT) production. It discusses that JIT is a Japanese manufacturing philosophy that aims to produce the right quality and quantity of items, at the right place and time to eliminate waste. The key concepts of JIT are the pull system where items are produced as needed rather than pushed through inventory, and eliminating waste at all stages of production. Kanban cards are also discussed as they signal what and how much to produce to match demand. Benefits of JIT include lower inventory levels, higher quality, and improved productivity. Limitations include the need for reliable suppliers and changes to company policies and procedures.

![Characteristics of JIT

Lower inventory levels

Small Lot Size

Reducing travel distance [Cellular Manufacturing]

Eliminate waste & defects

High quality levels

Standardization

Continuous improvement

Applicable primarily for repetitive operations

10](https://image.slidesharecdn.com/jit-150512022623-lva1-app6891/85/Just-In-Time-Production-JIT-10-320.jpg)