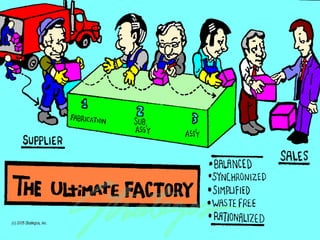

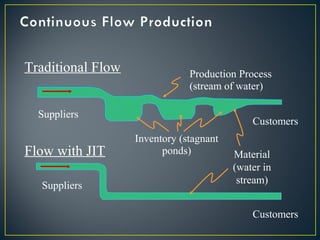

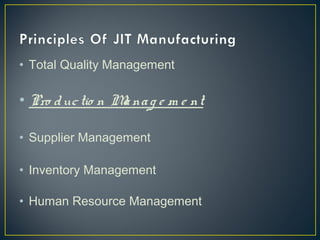

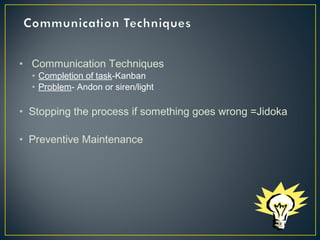

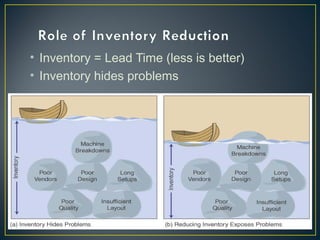

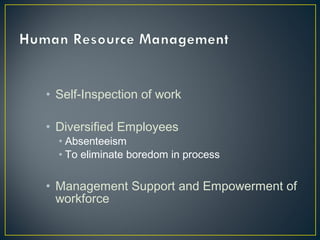

The document discusses the Just-In-Time (JIT) philosophy and its implementation. It begins by defining JIT as a philosophy of continuous improvement focused on prevention over correction through company-wide quality focus. It then provides details on: the origins and key aspects of JIT; how it differs from traditional production methods through reduced inventory and improved visibility; its implementation across total quality management, production, suppliers, inventory, and human resources; communication techniques used; types of waste addressed; and challenges to implementing JIT. Examples of companies successfully using JIT principles, like Toyota, Dell, and Harley Davidson, are also provided.