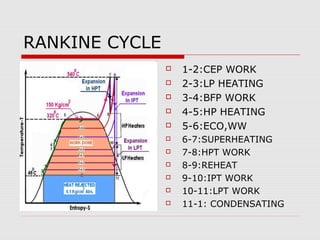

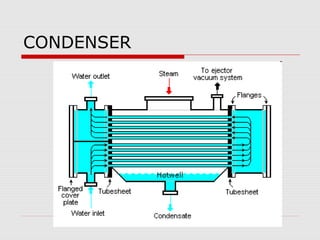

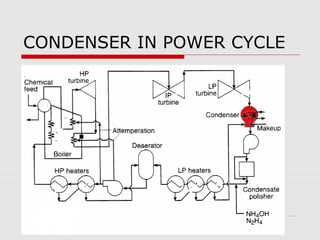

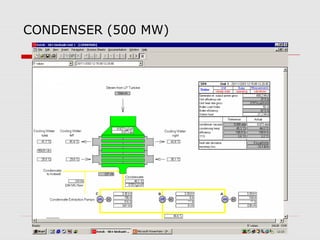

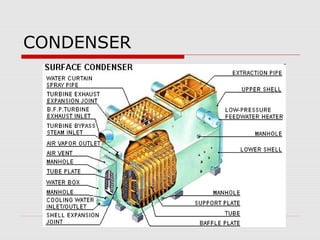

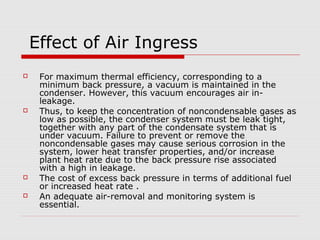

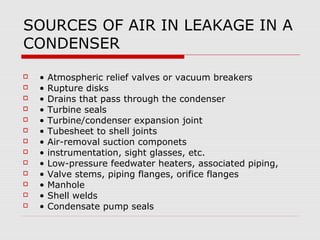

The document discusses condensers used in thermal power plants. It describes the functions of a condenser as condensing exhaust steam from turbines to be reused in the steam cycle, creating a vacuum to improve turbine efficiency, and removing non-condensable gases. Key aspects covered include the condenser's role in the Rankine cycle, operation, materials used for tubes, sources of air leakage, methods for detecting water leakage into tubes, and cleaning and testing of condenser tubes.