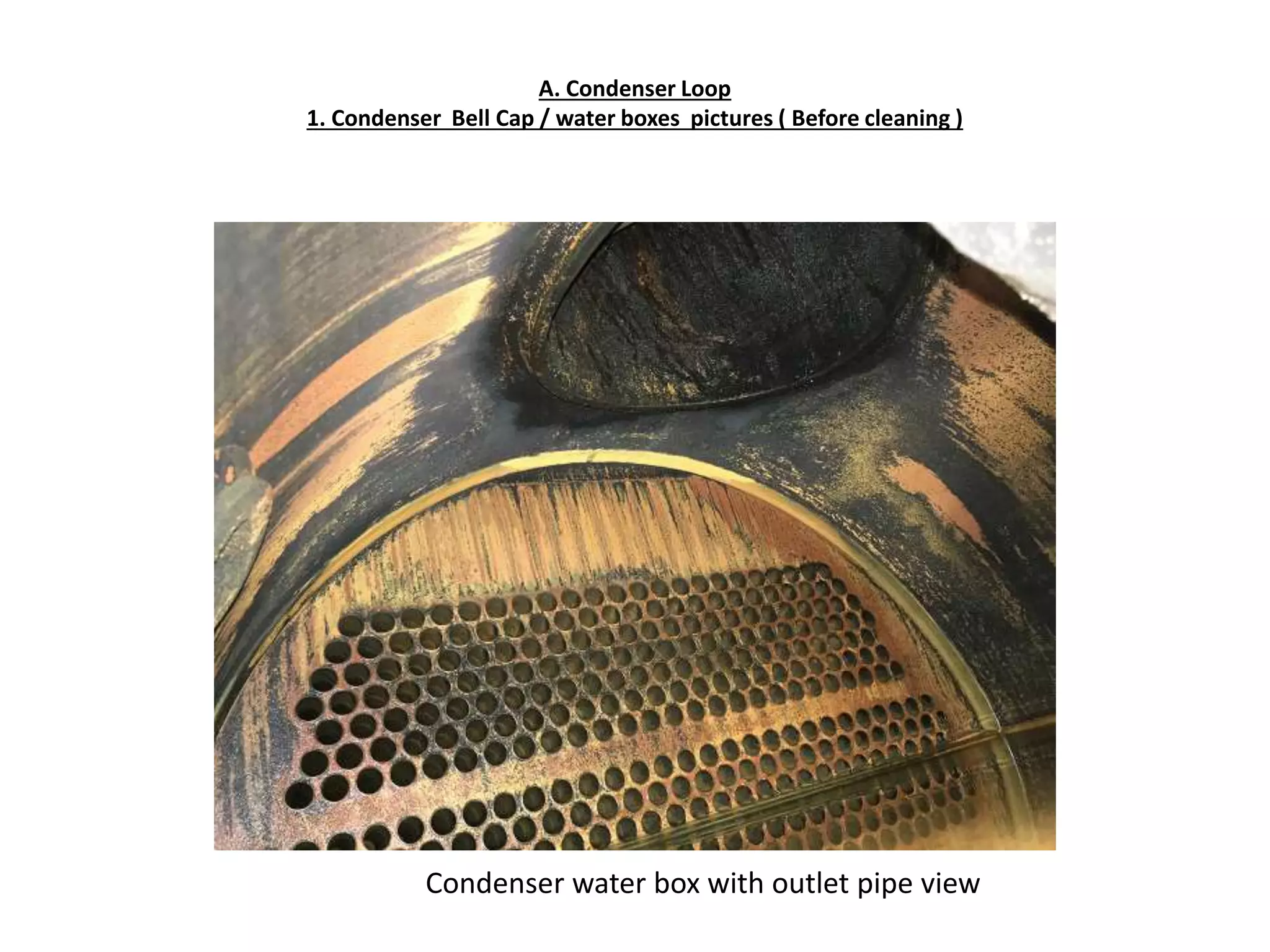

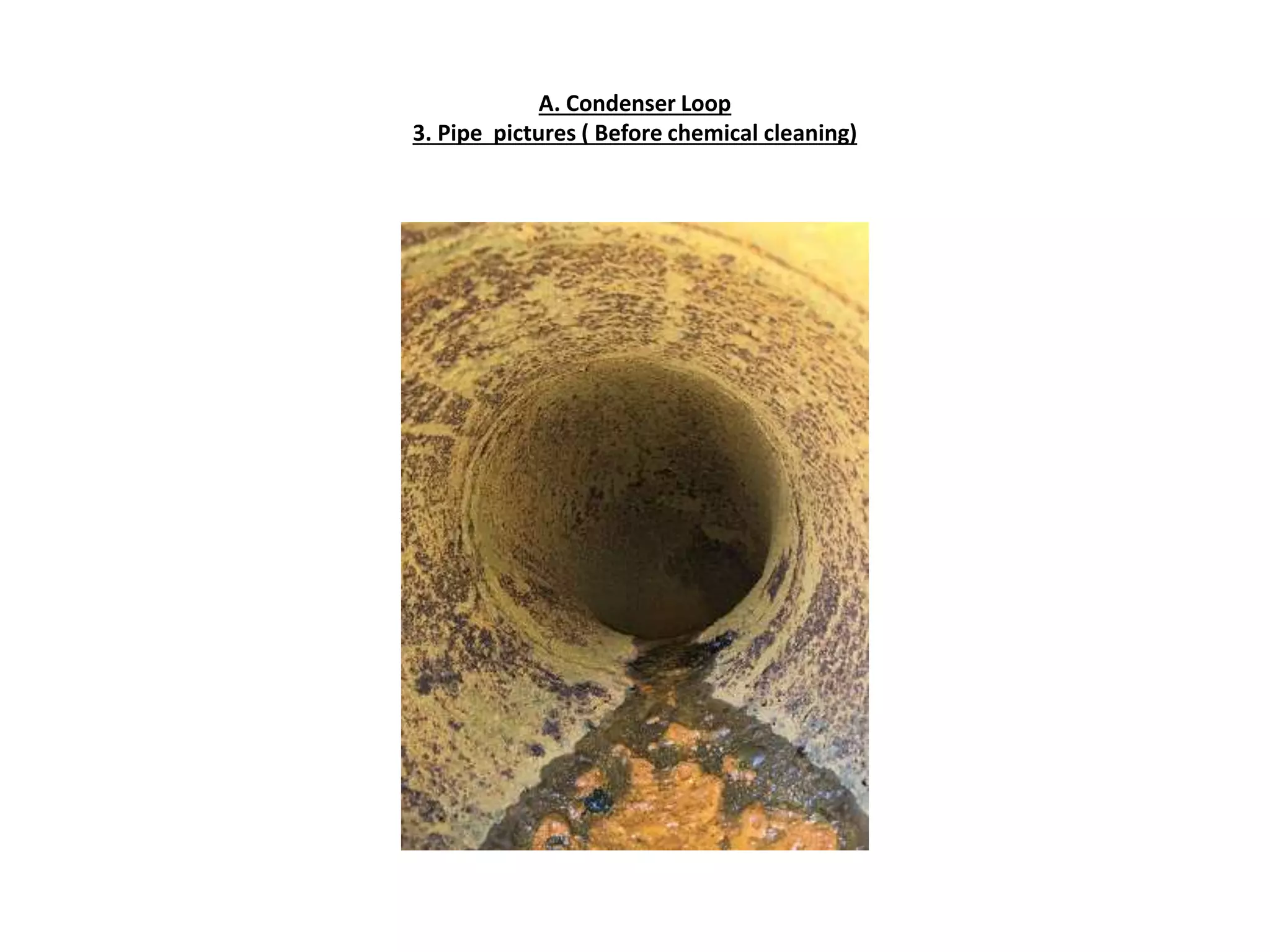

The document describes repair and cleaning work done on chillers 6 and 7 at a building in Bahrain. Pictures are provided showing the condition of components before and after the work. Work included cleaning condenser tubes and loops through brushing, chemical flushing, and painting. The refrigerant loop was cleaned through recovery, flushing, vacuuming and filter recycling of refrigerant. Other tasks included replacing filters, oil, and switches, installing sensors, and aligning pumps. The work aimed to remove contaminants and deposits from the chillers' condenser and refrigerant loops.