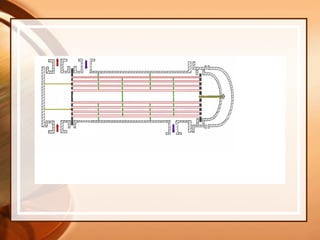

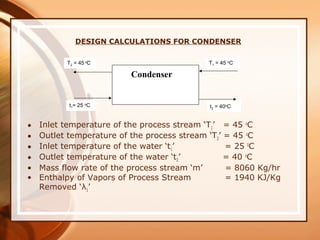

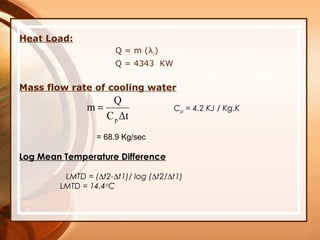

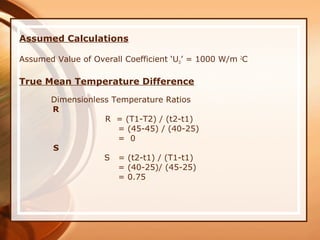

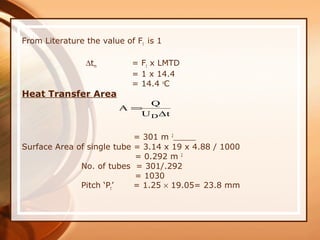

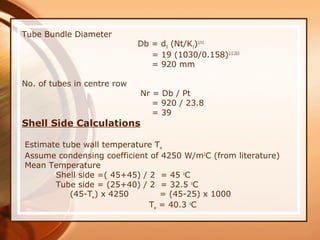

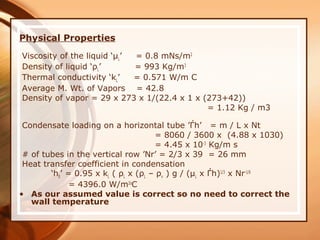

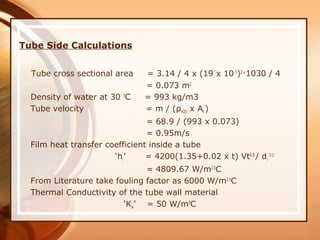

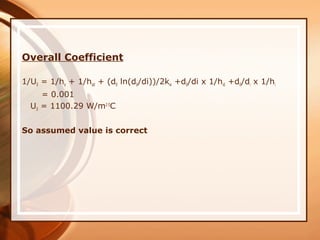

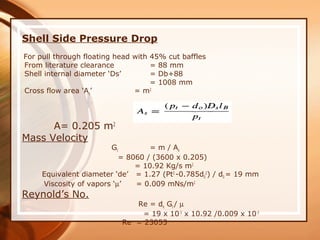

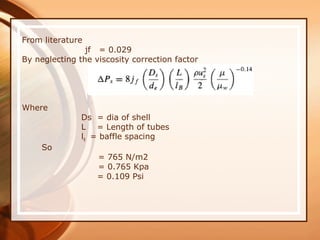

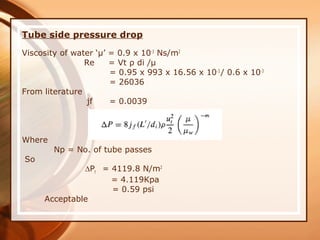

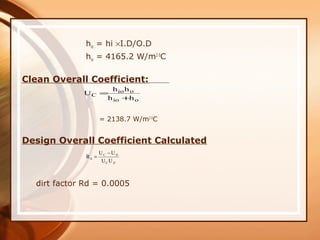

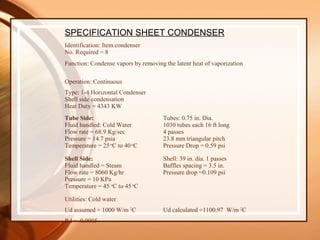

A condenser is a heat exchanger that transfers vapors into a liquid state by removing latent heat with a coolant like water. This document provides design calculations for an 8 unit shell and tube condenser with 1030 tubes that uses cold water as the coolant to condense steam at a rate of 8060 kg/hr and 4343 kW of heat duty. Key specifications are provided, like a calculated overall heat transfer coefficient of 1100.97 W/m2C and pressure drops of 0.59 psi for the tube side and 0.109 psi for the shell side. References on condenser design are also listed.