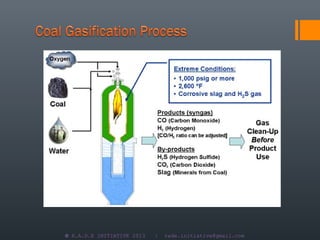

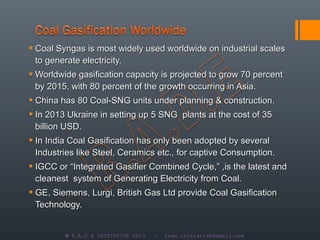

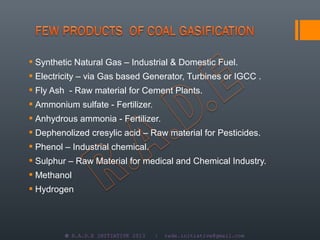

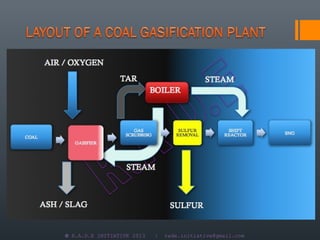

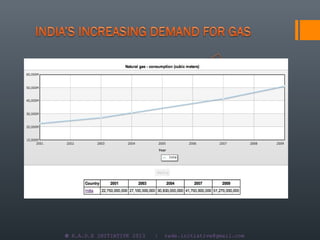

Coal mining in Assam started in 1870, with the northeastern region holding only 0.37% of India's total coal reserves. Gasification of coal can produce syngas, a cleaner alternative to coal combustion, with applications in electricity generation and as industrial fuel. The document highlights the potential for higher efficiency and reduced pollution through gasification, alongside the various products derived from this process.