Embed presentation

Downloaded 574 times

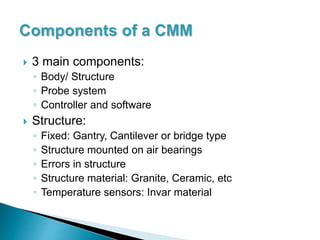

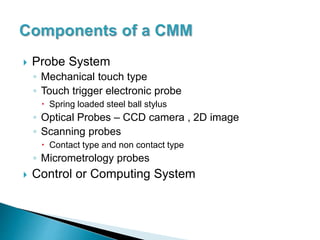

CMM is a 3D measuring device used to measure dimensional characteristics of objects. It has three main components - a structure, probe system, and controller/software. Traditional CMMs have a fixed gantry structure and use touch probes to manually or automatically measure points. New developments include non-contact probes, faster computing, and portable CMMs suited for shopfloor use.