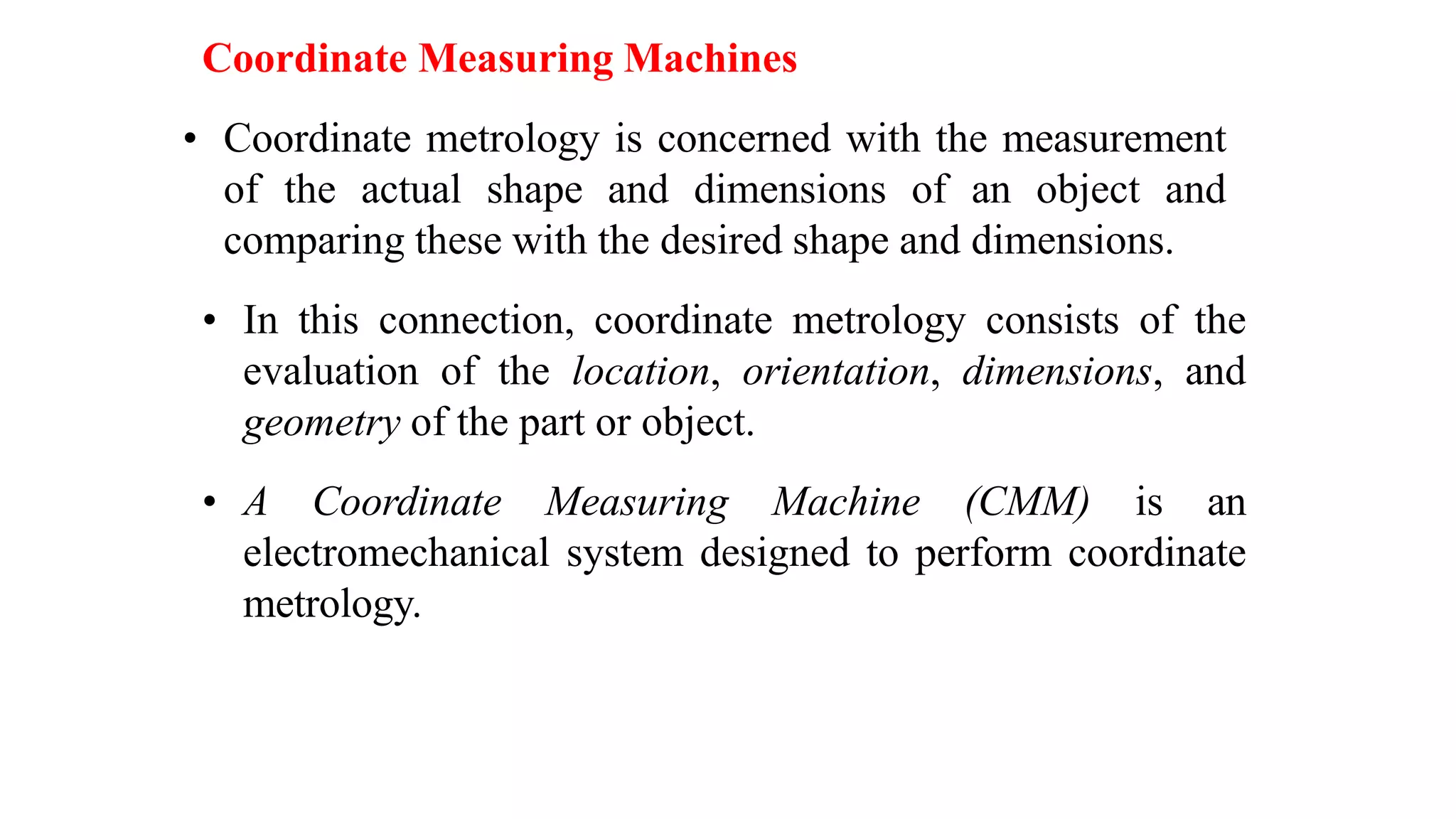

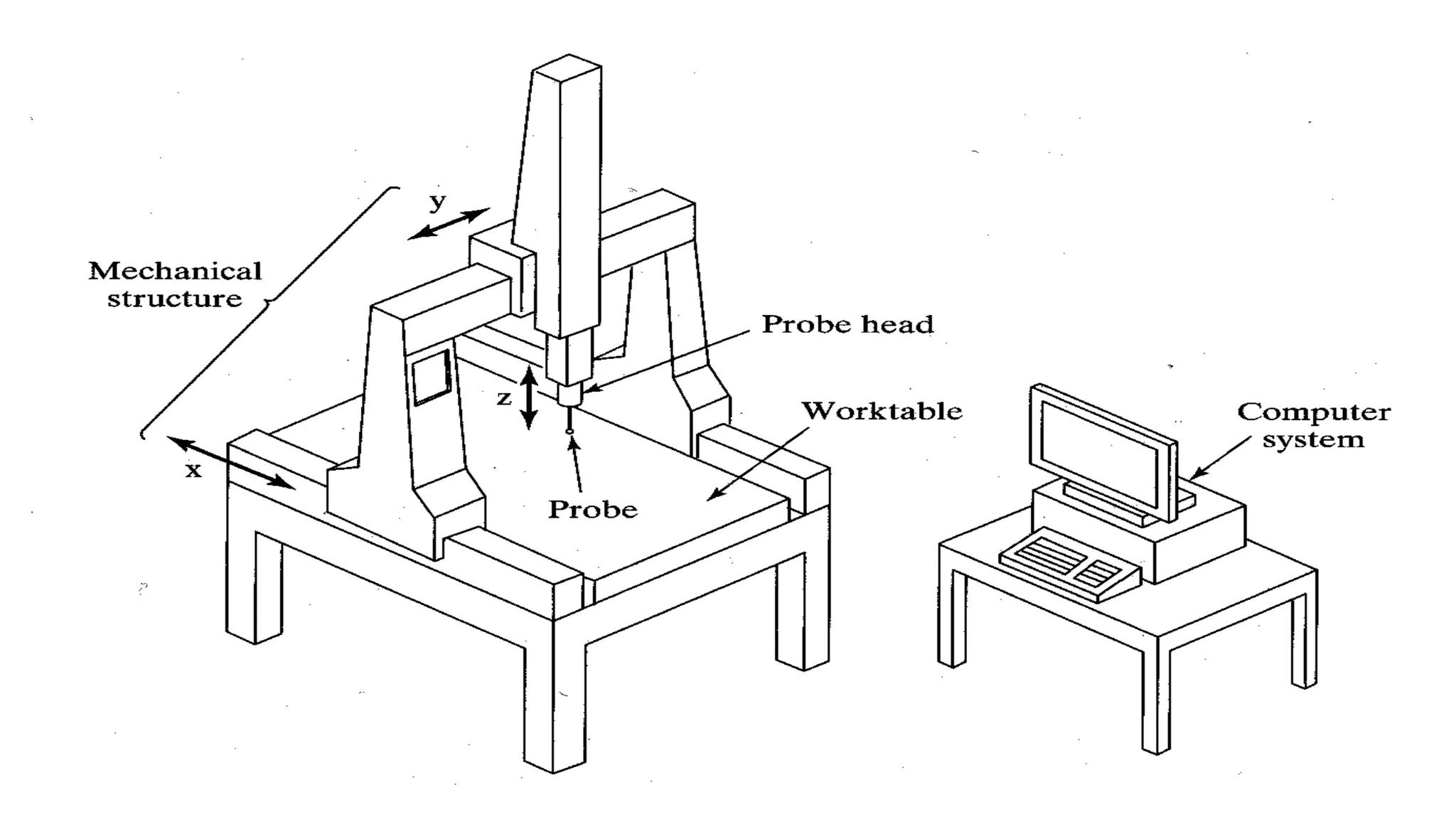

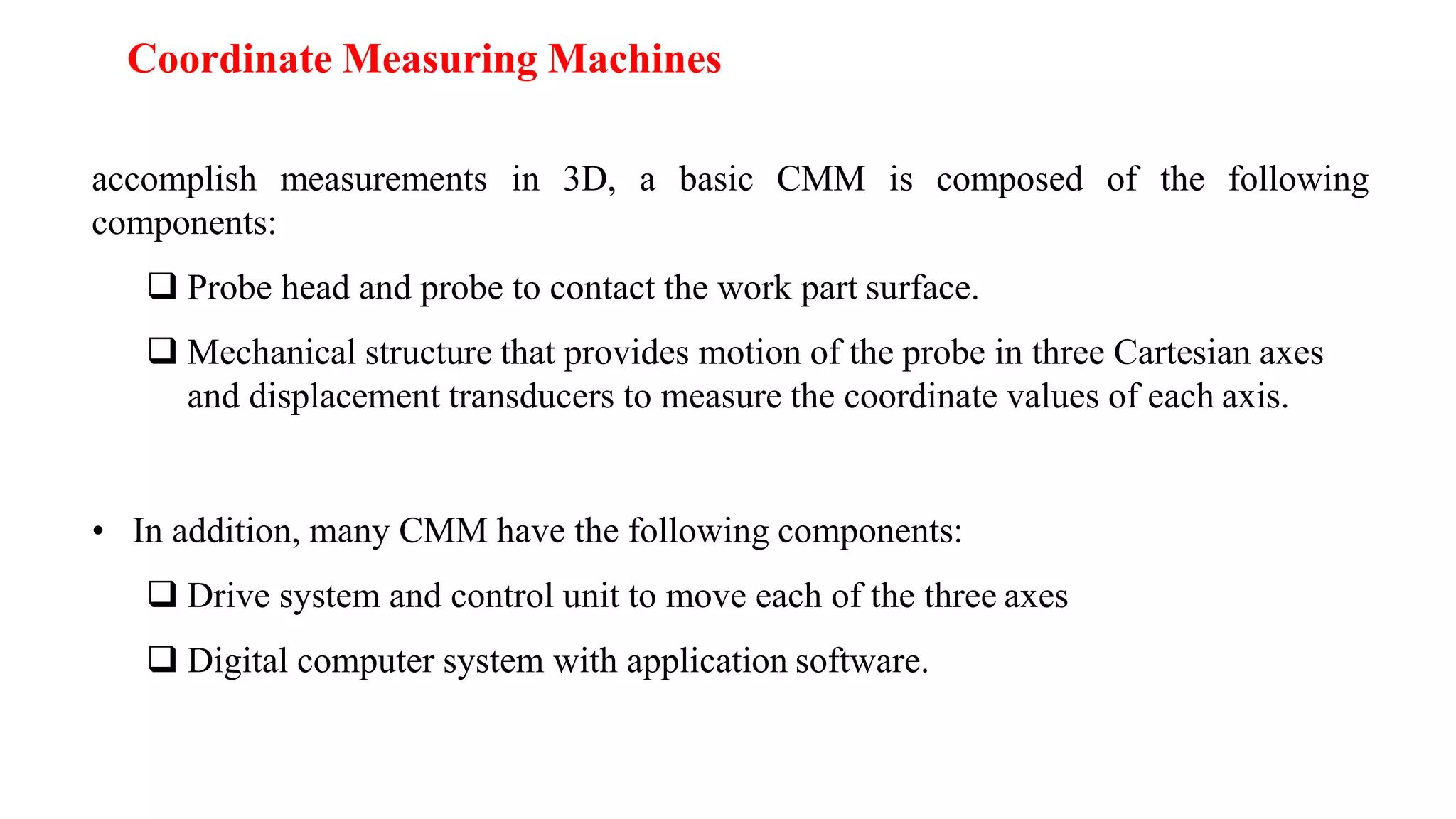

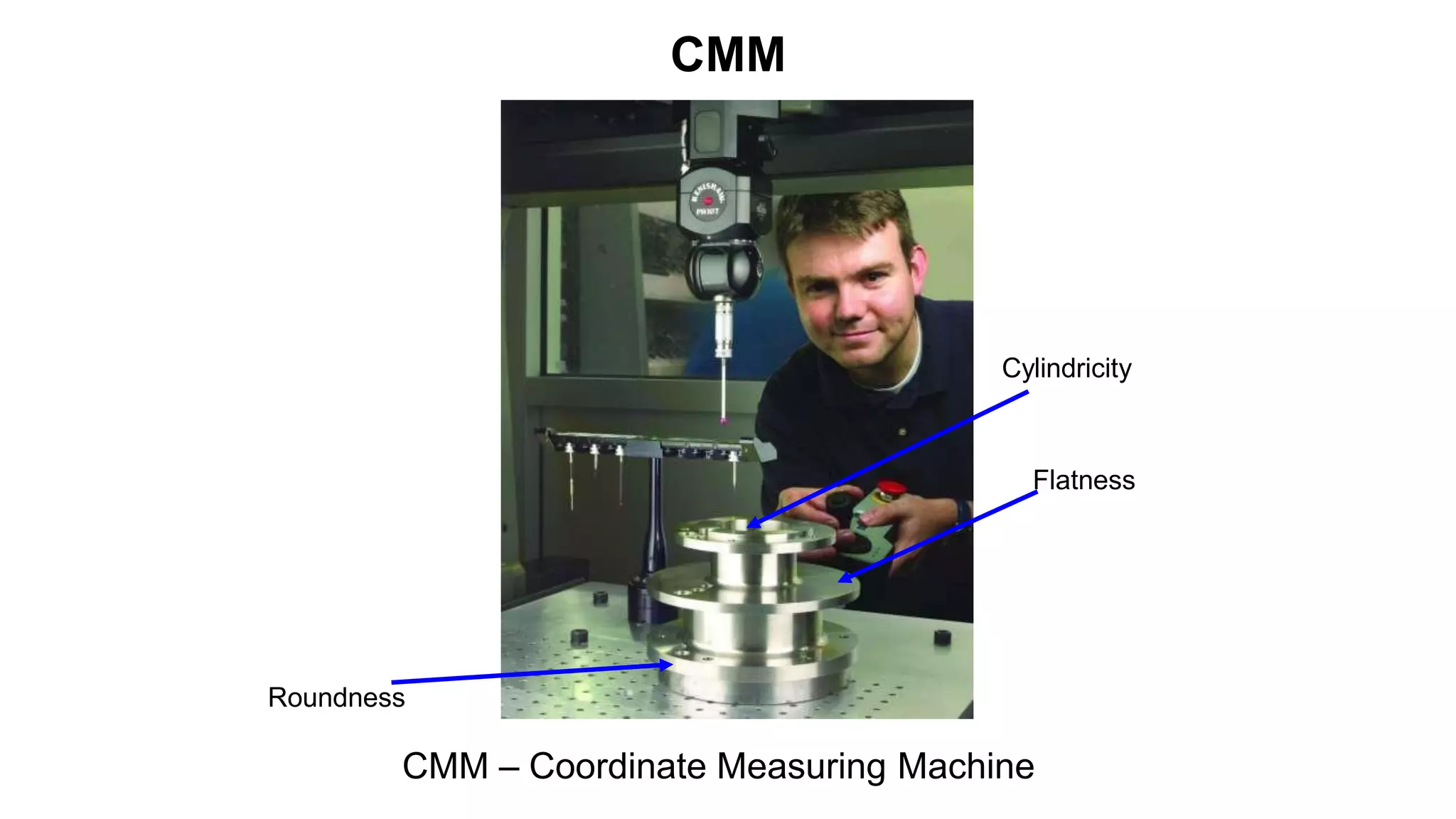

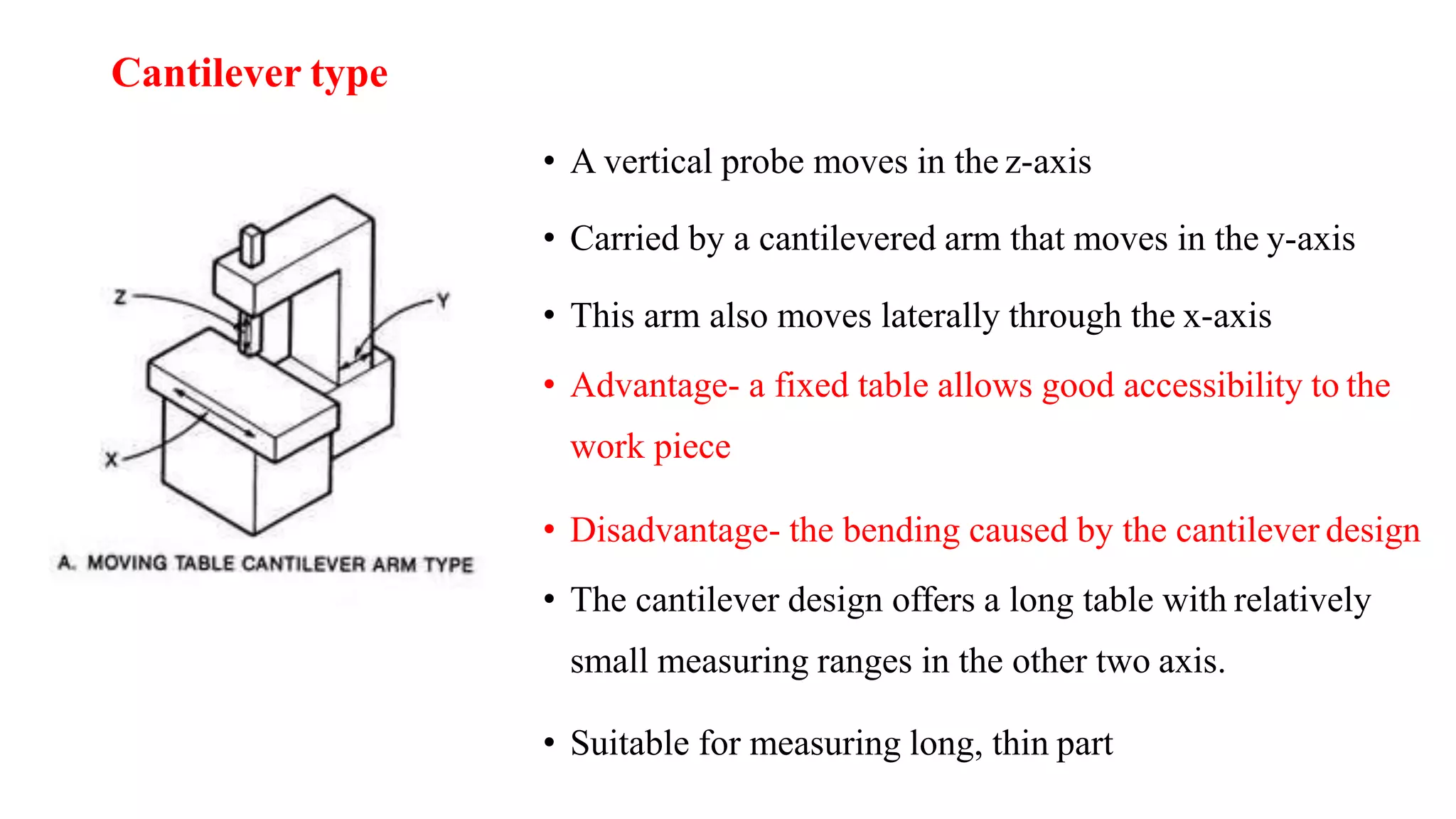

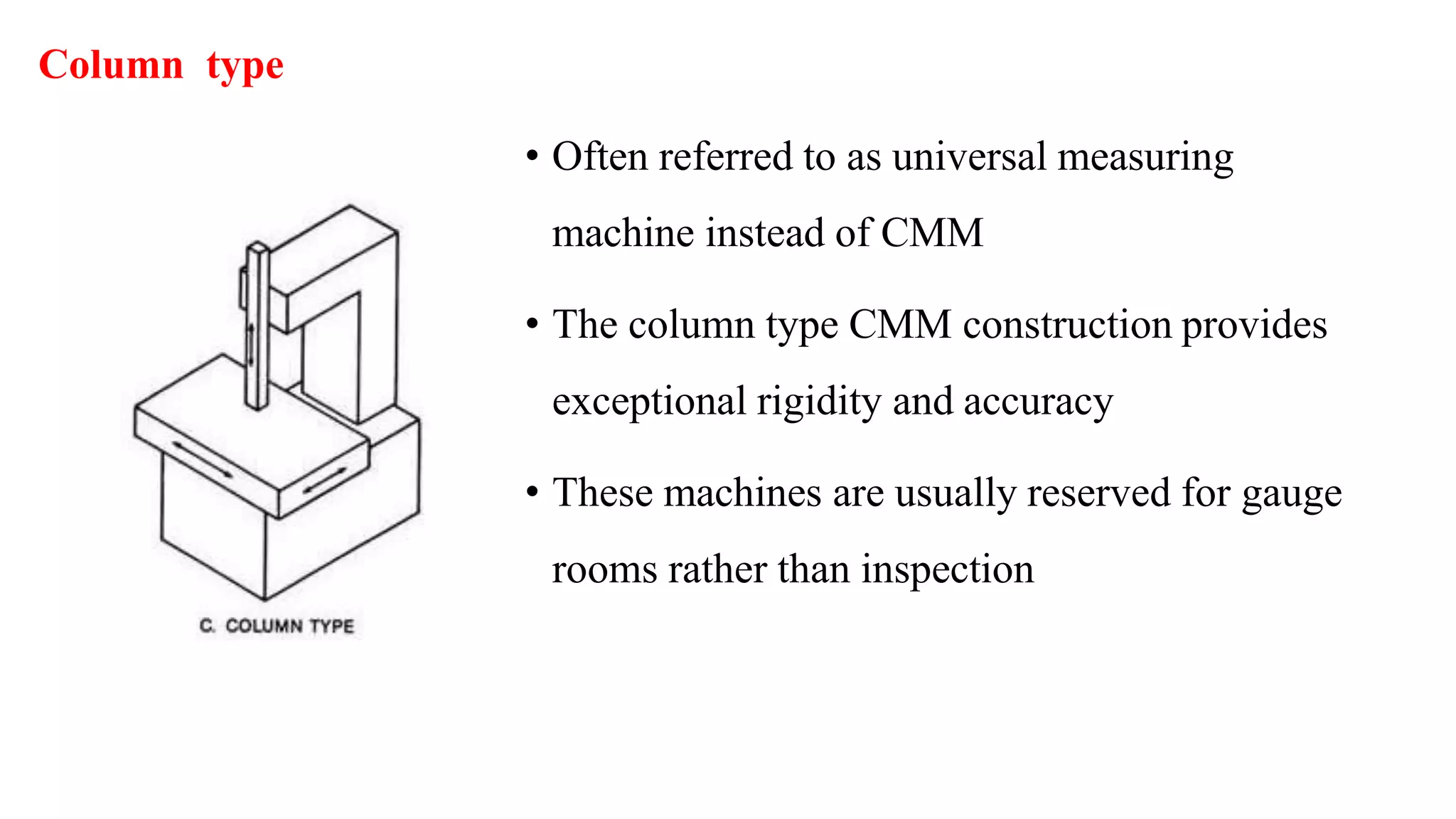

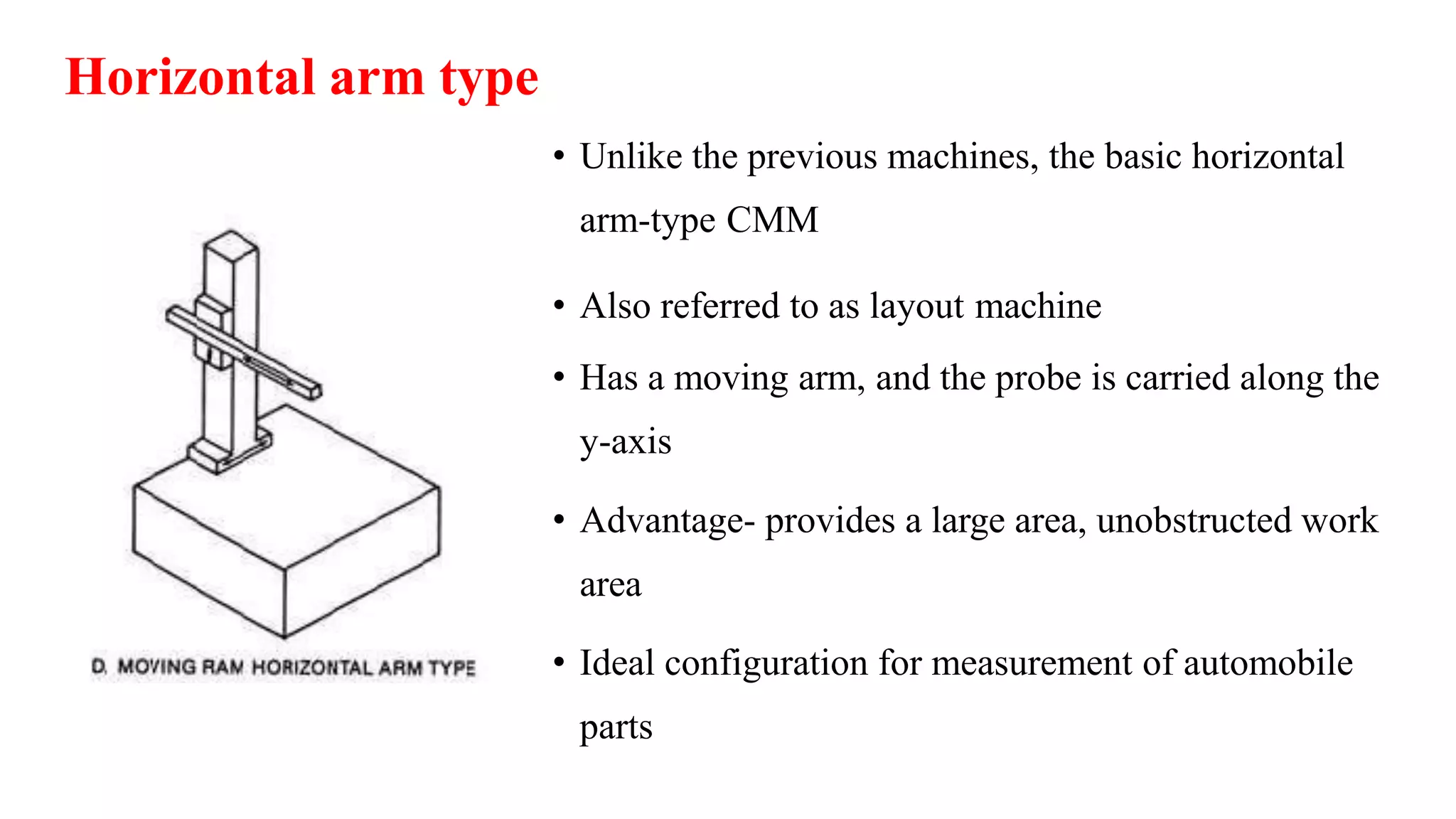

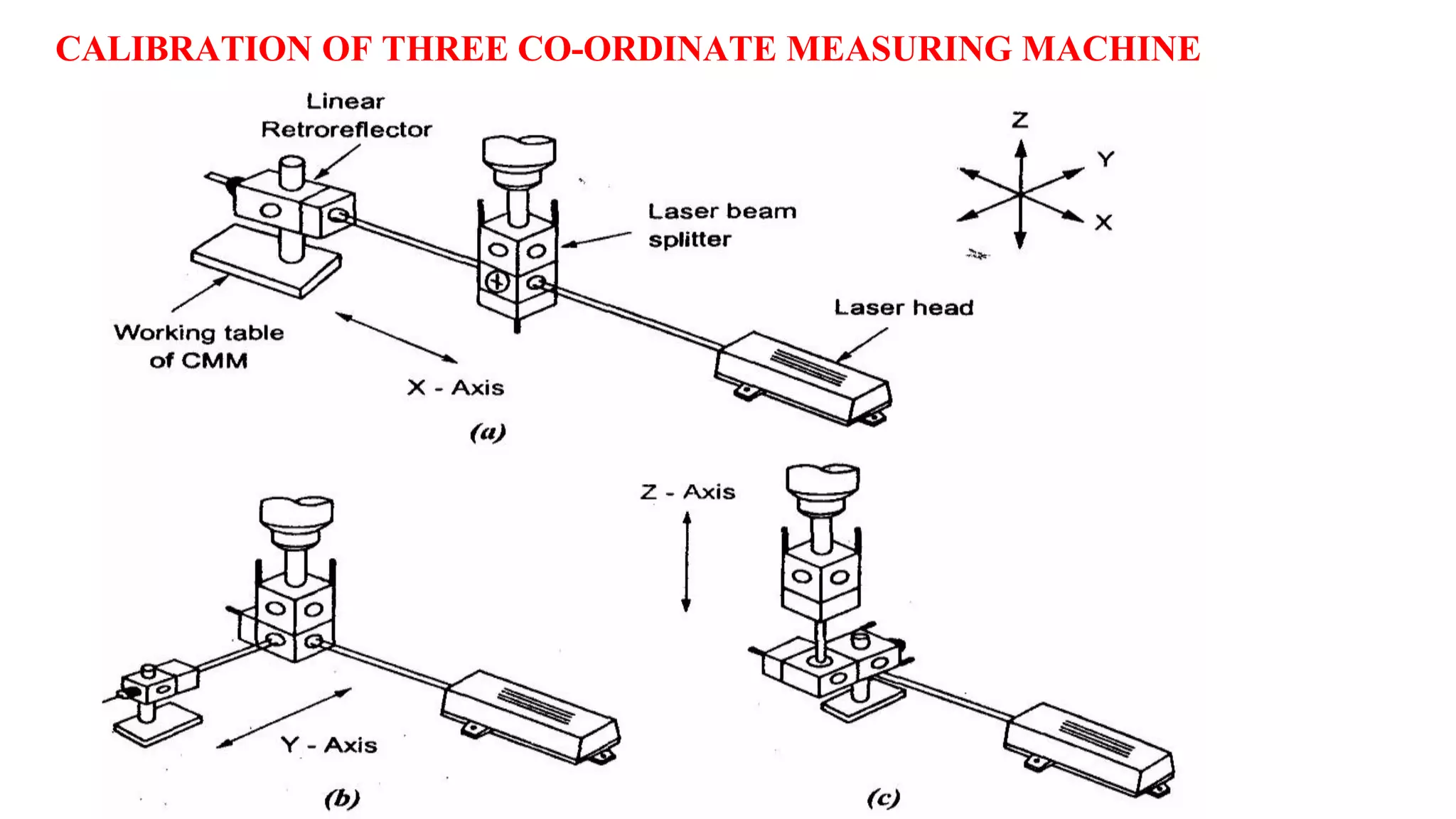

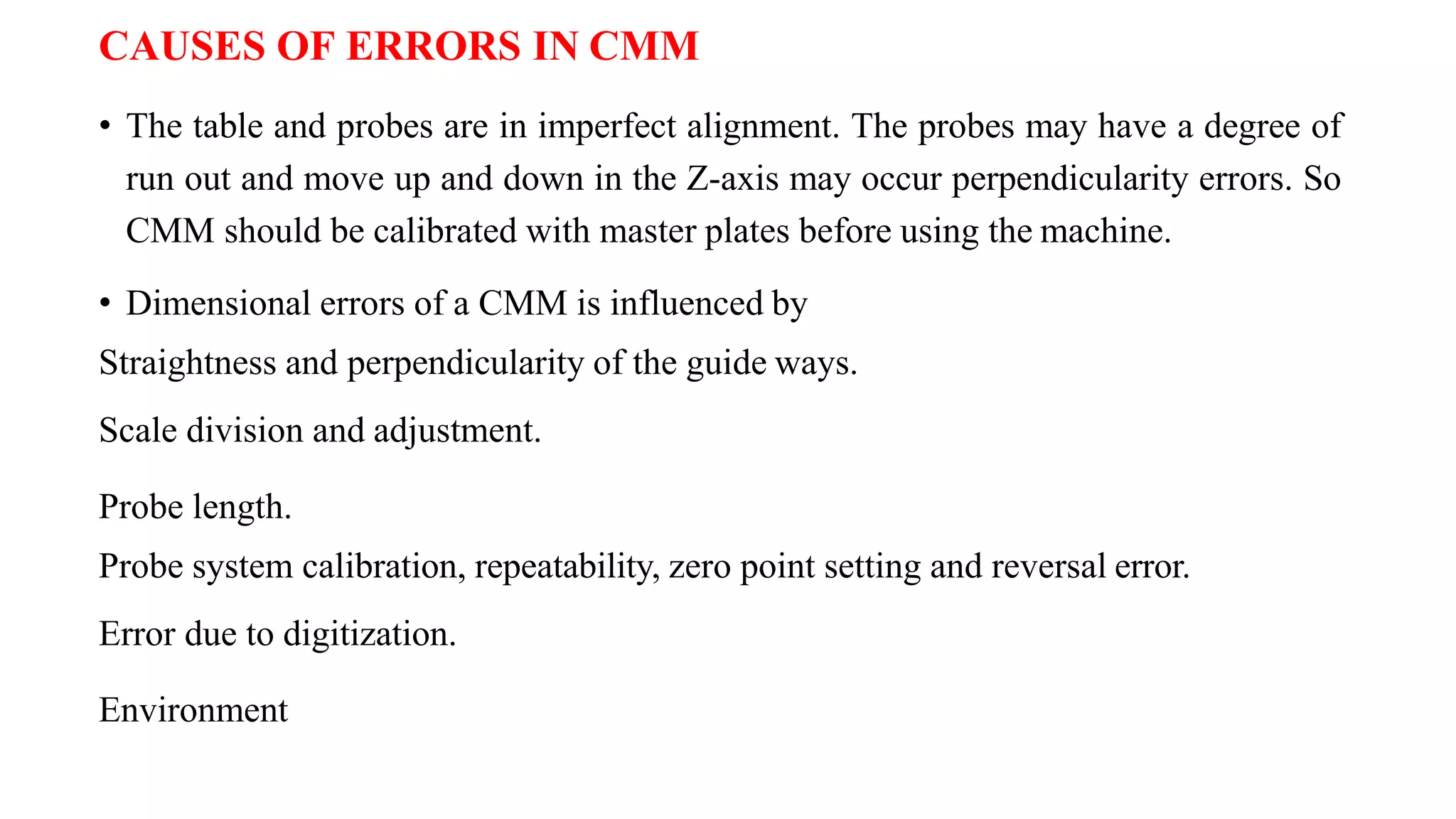

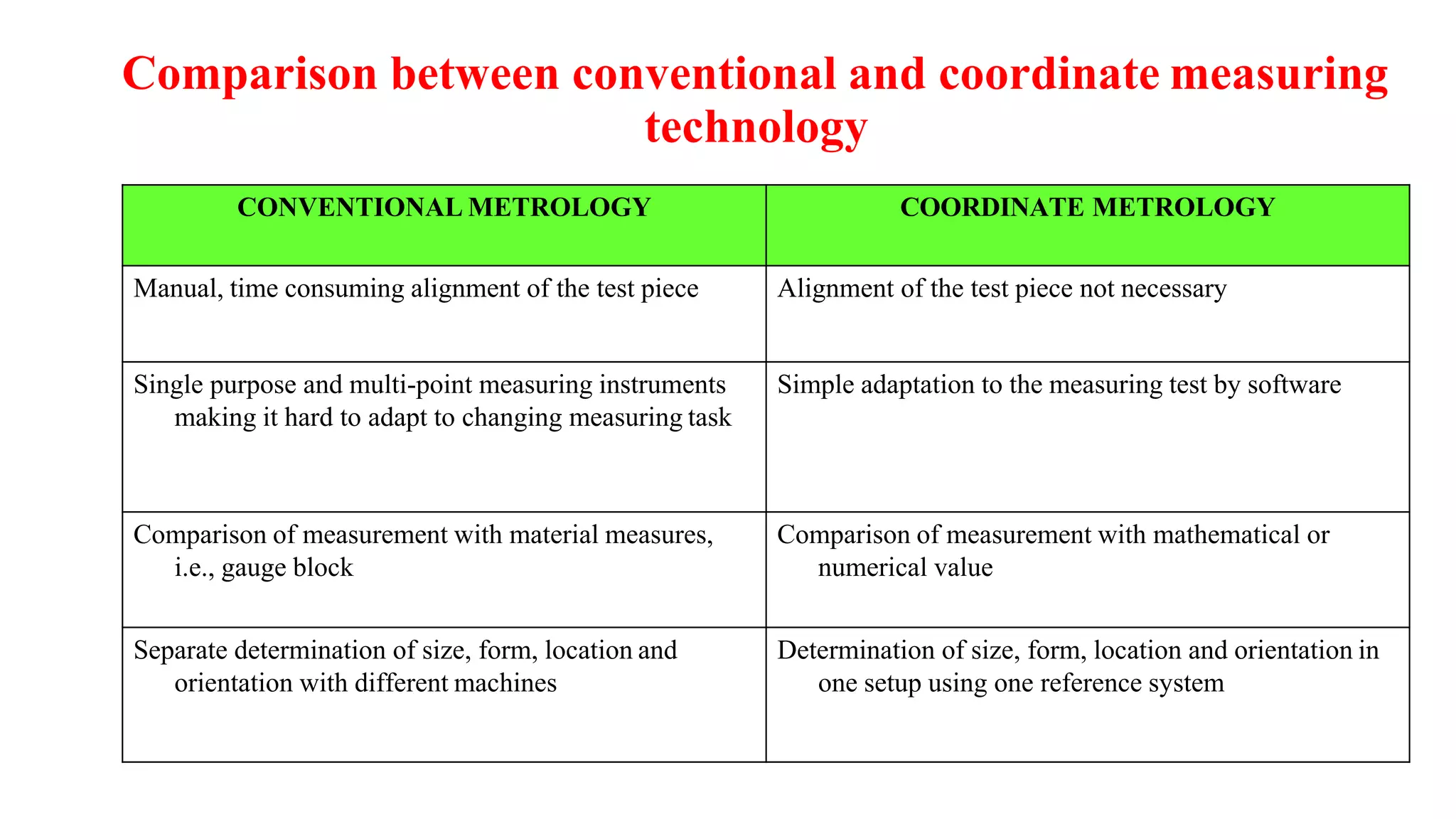

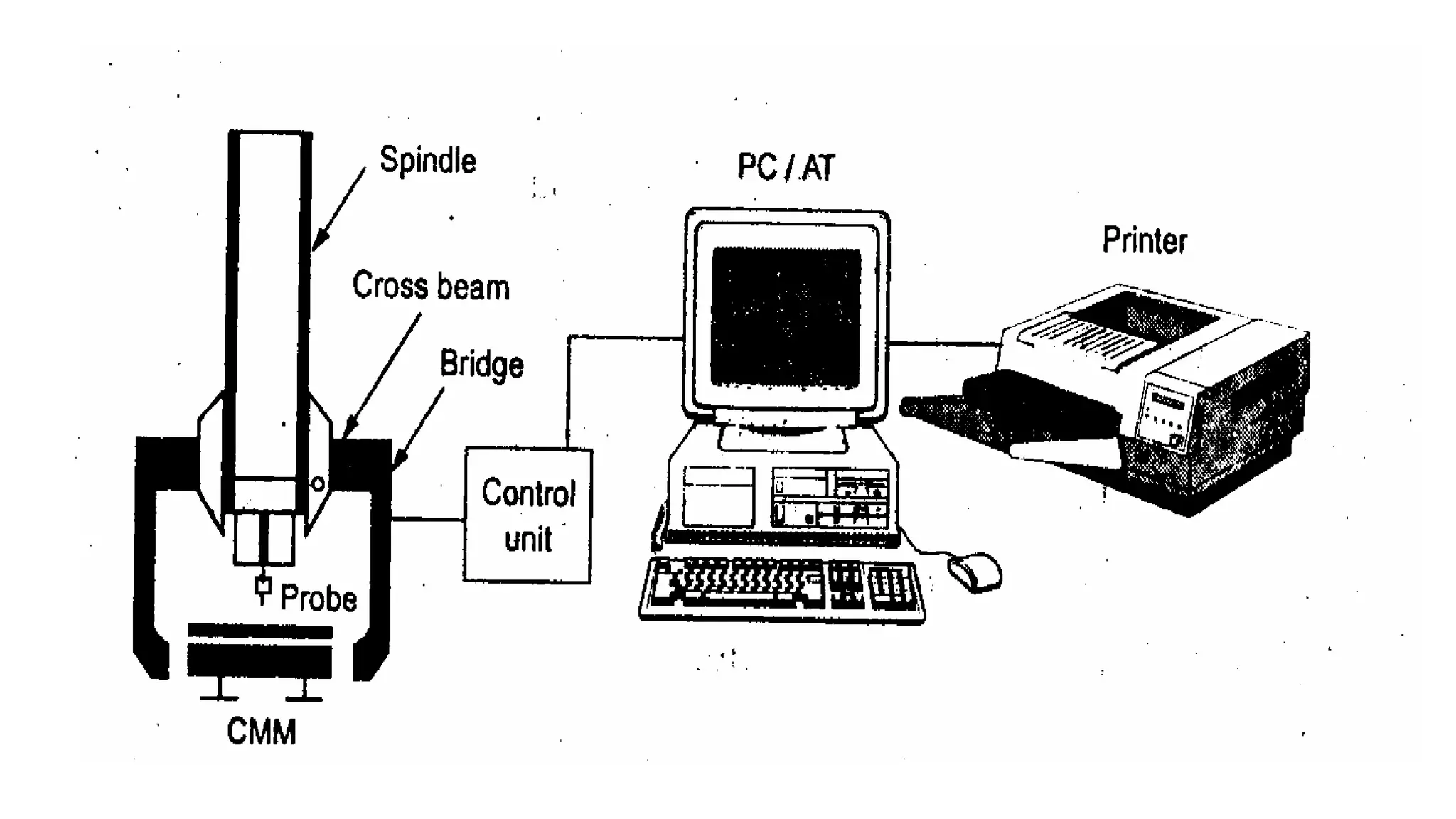

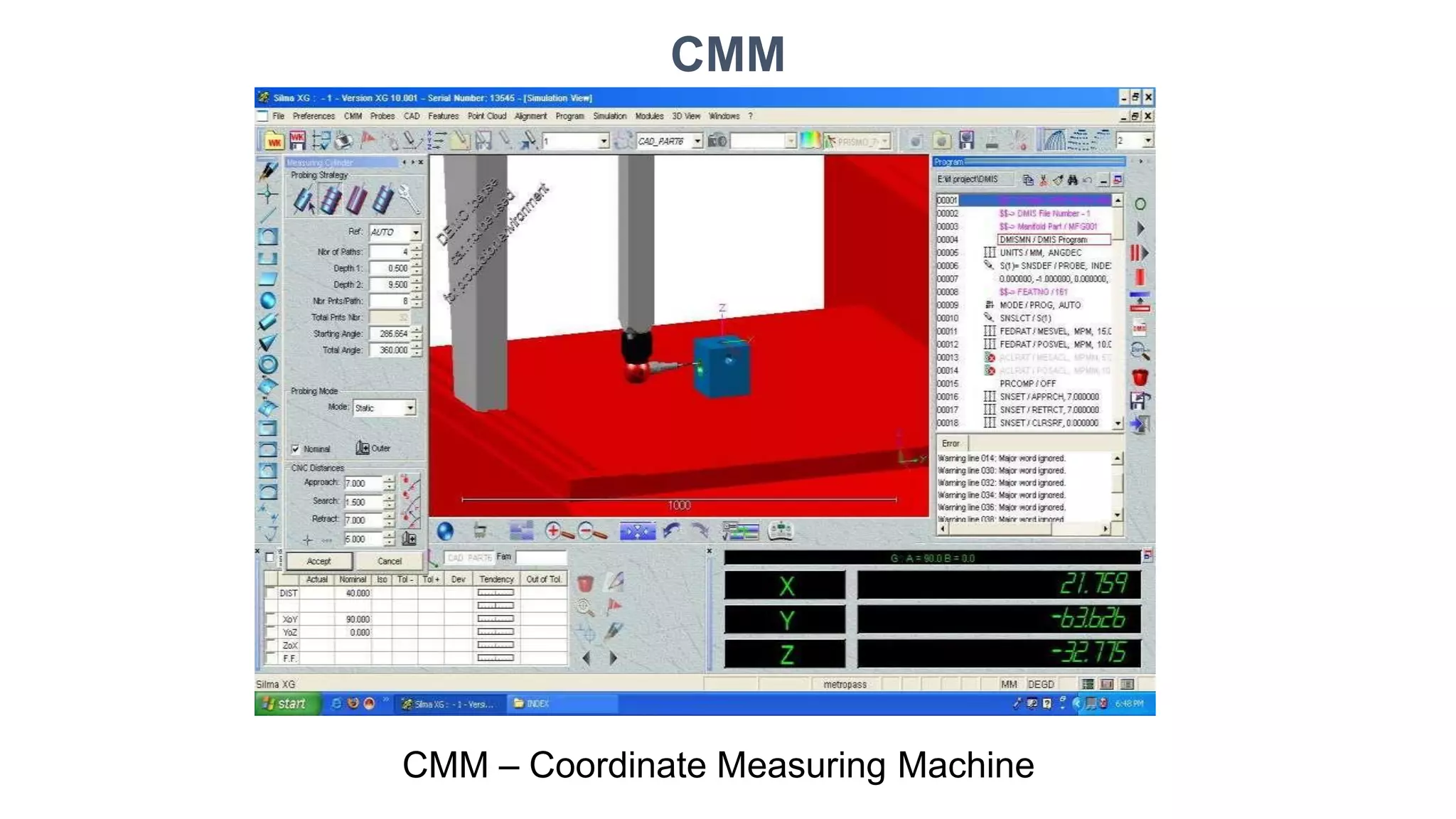

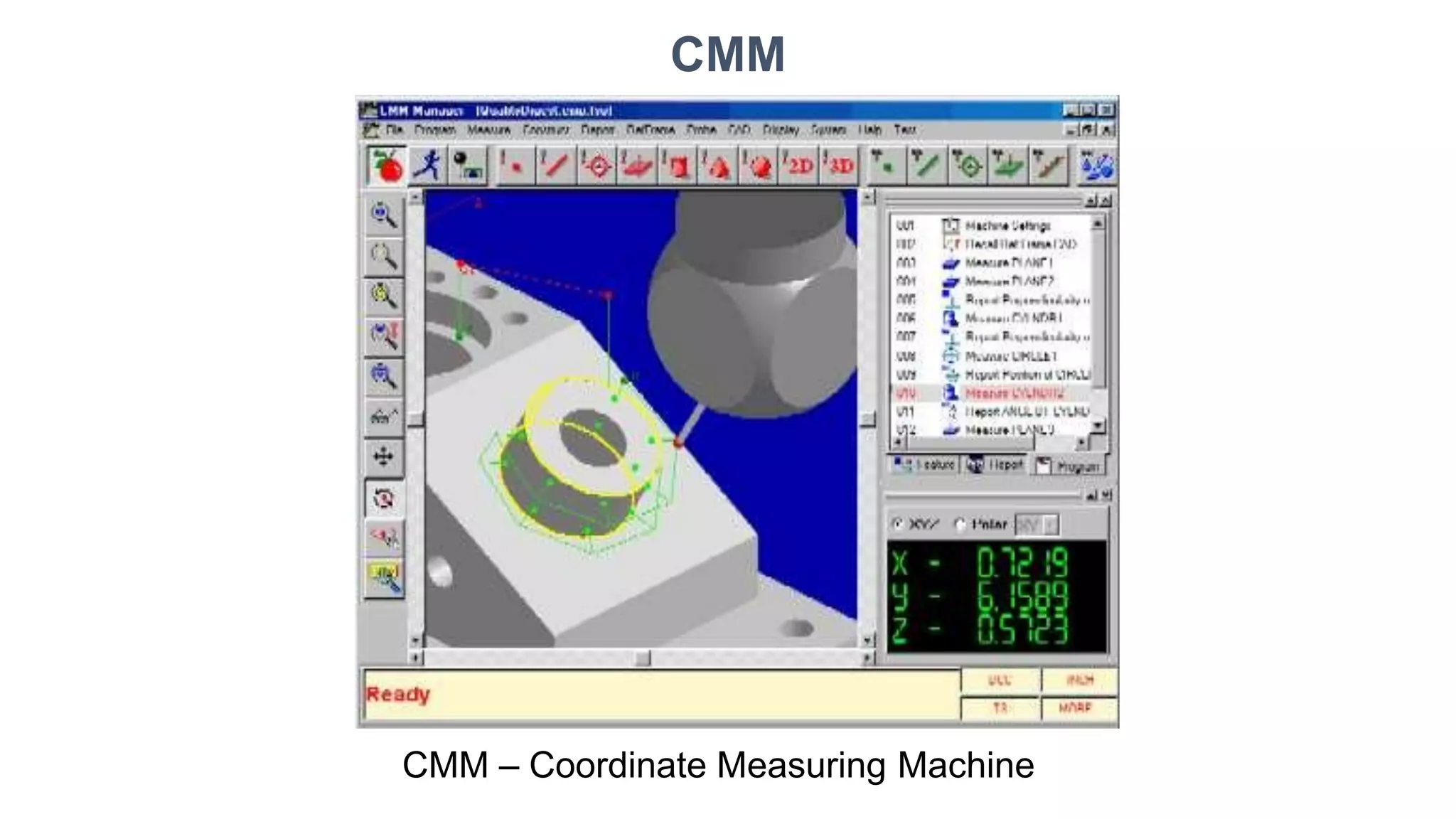

The document outlines the principles and components of coordinate measuring machines (CMMs) used in metrology and quality control, highlighting various types of CMMs and their operational programming methods, including both manual and computer-controlled systems. It details the advantages and disadvantages of CMMs, emphasizing their applications in diverse industries for precision measurement and inspection tasks. Additionally, it discusses the importance of calibration, potential error sources, and contrasts coordinate metrology with conventional metrology practices.