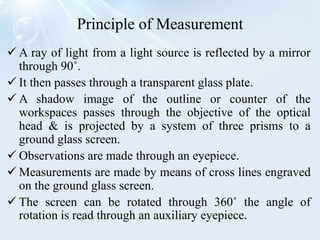

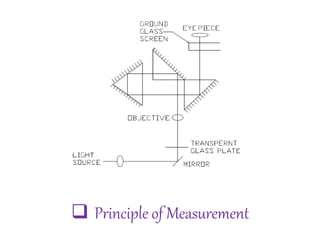

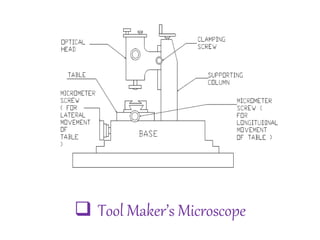

The toolmaker's microscope is an optical measuring device that can measure lengths, profiles, angles, and threads up to 1/100th of a millimeter. It works on the principle of projecting a shadow image of the workpiece through an optical system onto a screen with cross lines, allowing measurements to be taken. Key components include a base, measuring head with light source and lenses, and a glass table with scales for measuring movement in the X, Y, and rotational directions. It can be used to accurately measure various mechanical components and perform tasks like thread measurement and angle measurement of tools.