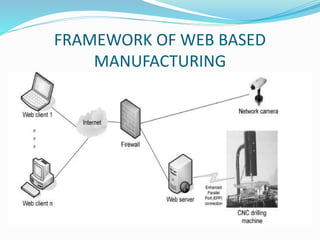

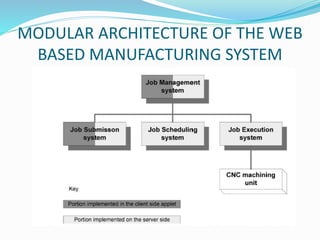

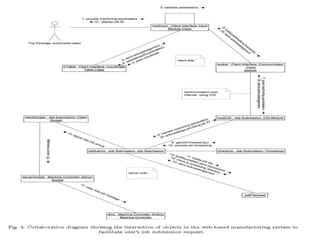

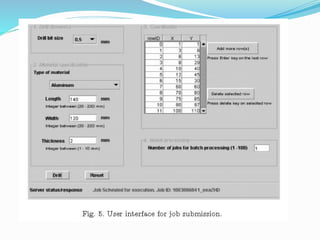

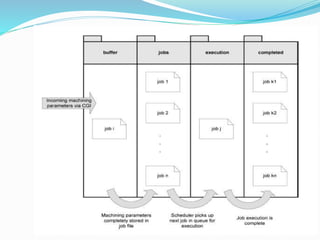

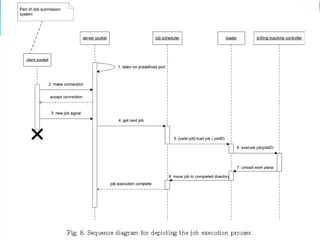

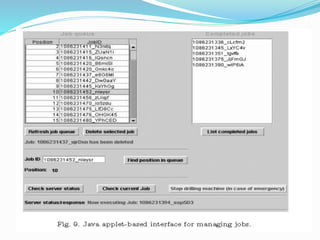

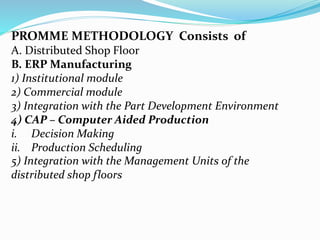

This document discusses web based manufacturing. It introduces web based manufacturing and explains some of its key benefits, including capturing a global audience, handling data issues, coordinating multi-user access, and reducing susceptibility to communication delays. It then describes the framework of web based manufacturing systems, including the modular architecture and processes like job submission, scheduling, storage, execution, monitoring, and management. Finally, it discusses some methodologies for implementing web based manufacturing systems, including using ERP systems, a web machining methodology, and the PROMME methodology.