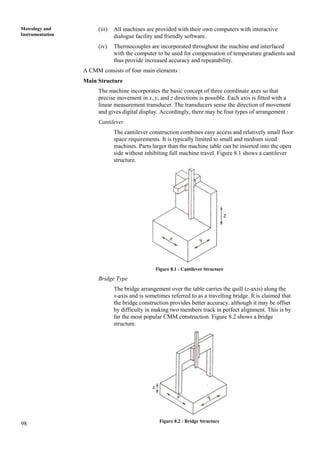

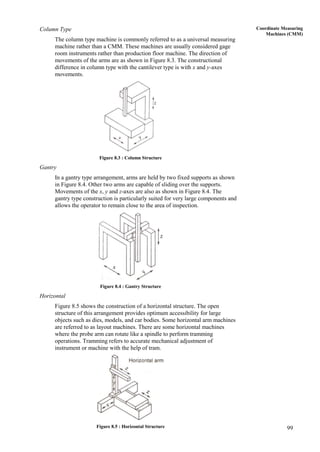

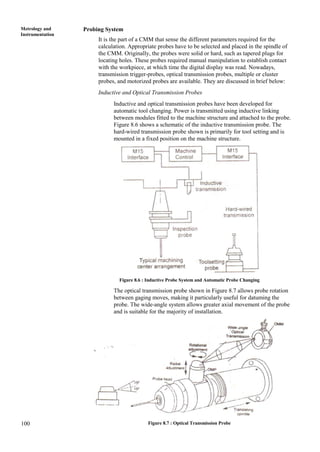

The document discusses coordinate measuring machines (CMMs). It describes CMMs as machines that use probes to precisely and accurately measure the geometry of physical parts. CMMs allow for fast, automated inspection and can provide measurements with micron-level accuracy. The document outlines the key components of CMMs, including their rigid base structures, probing systems, computer controls, and inspection software. It also discusses how CMMs are integrated into computer-aided manufacturing systems to enable bi-directional communication between design and inspection data.