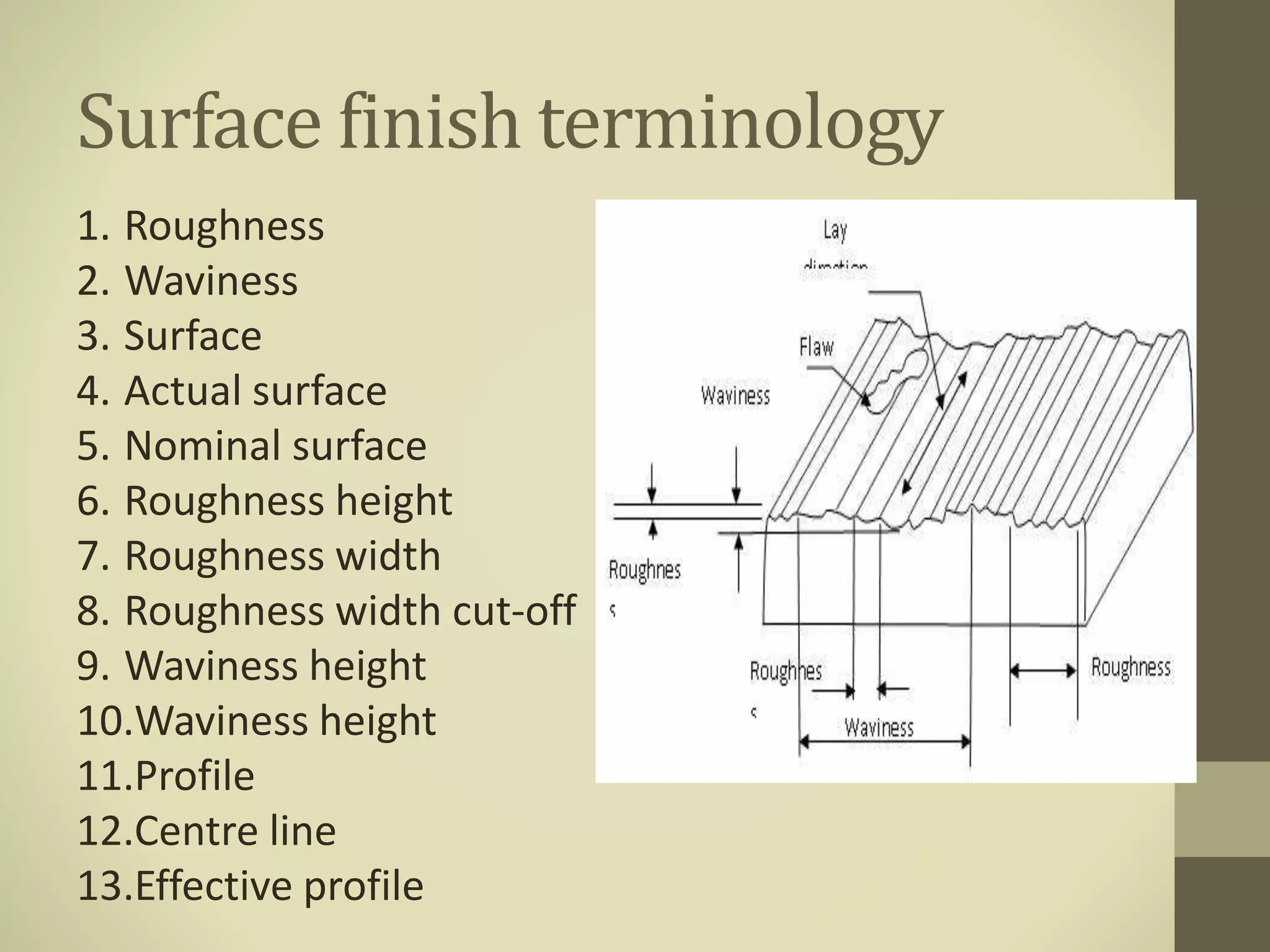

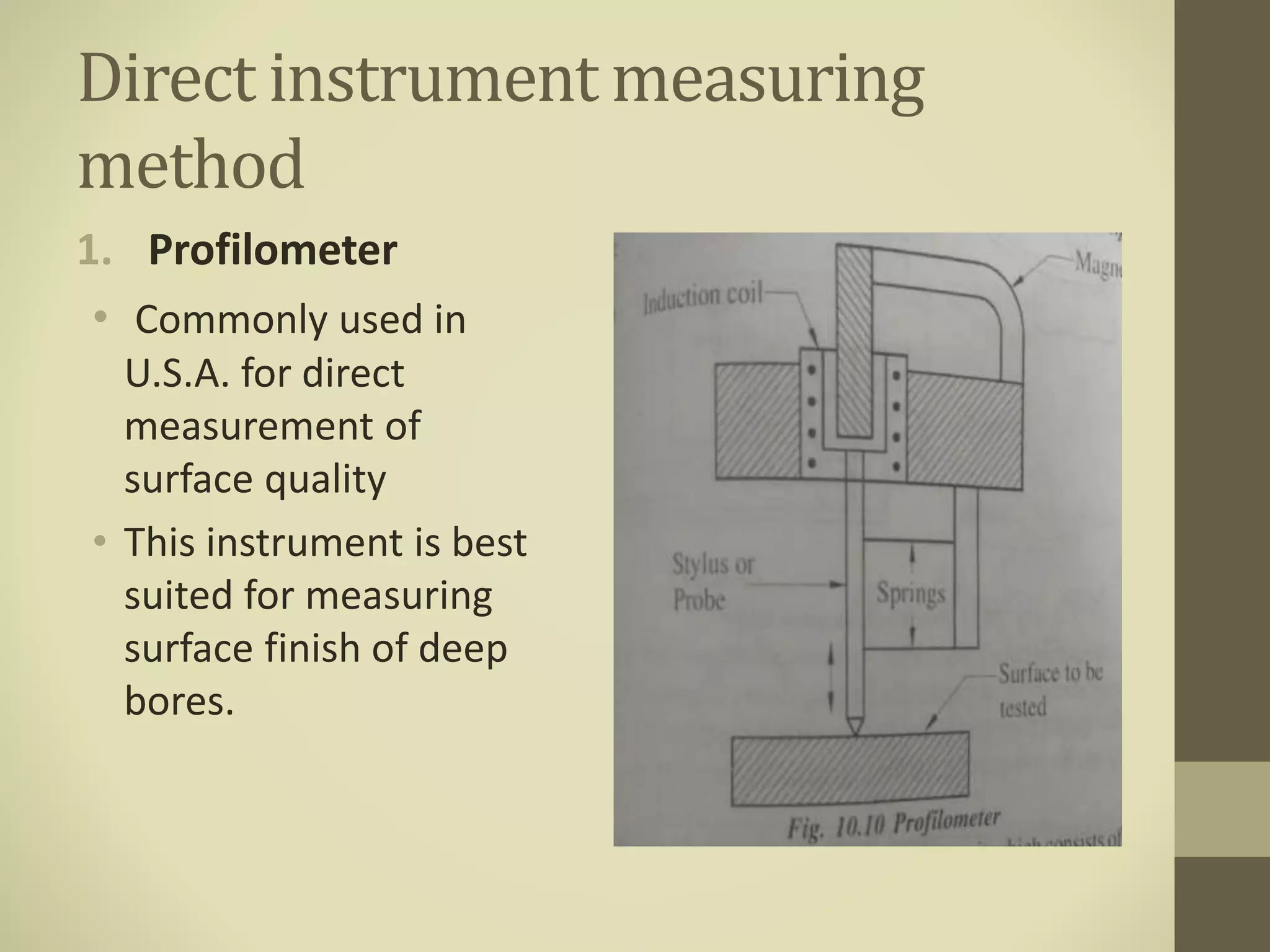

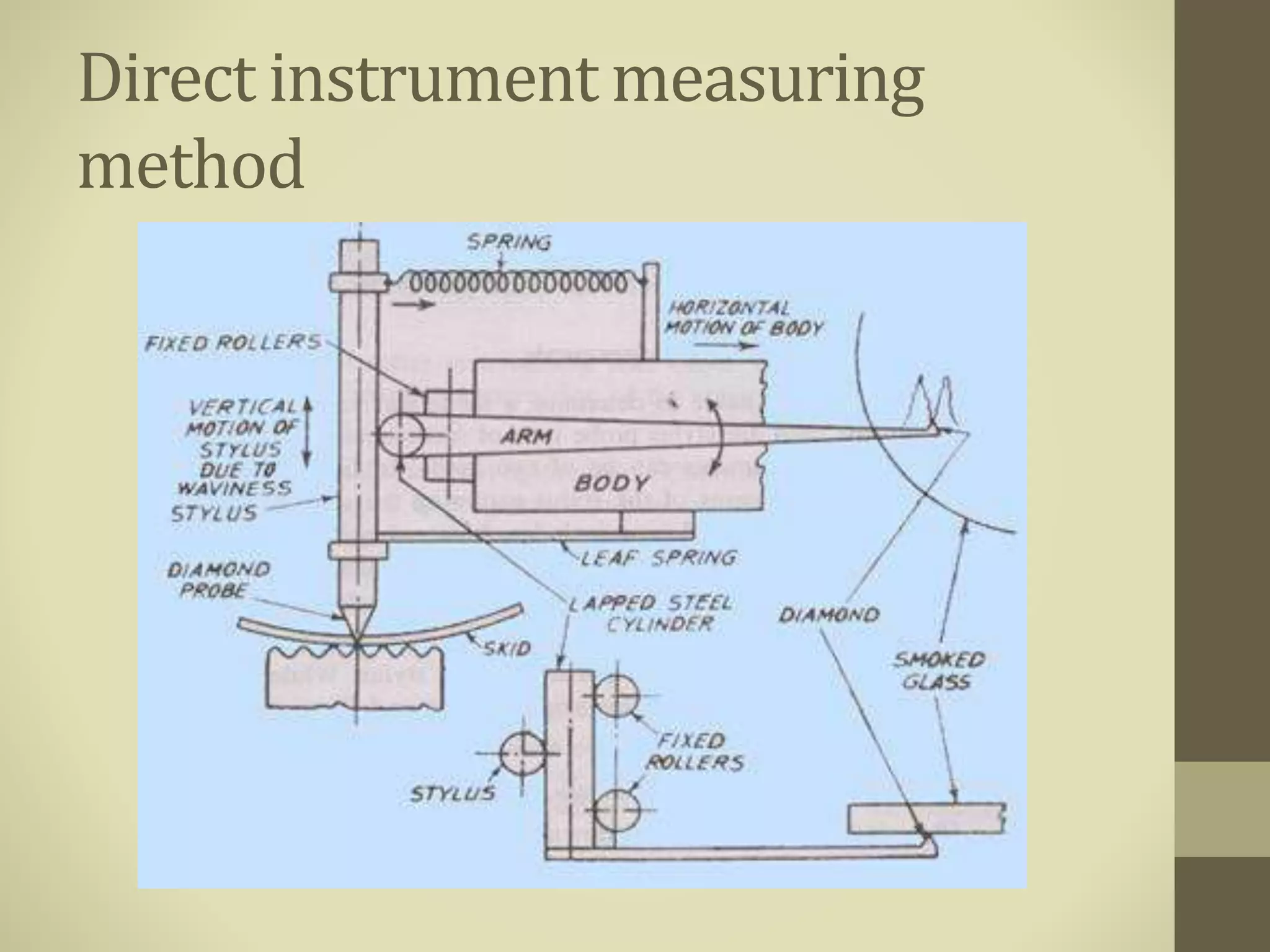

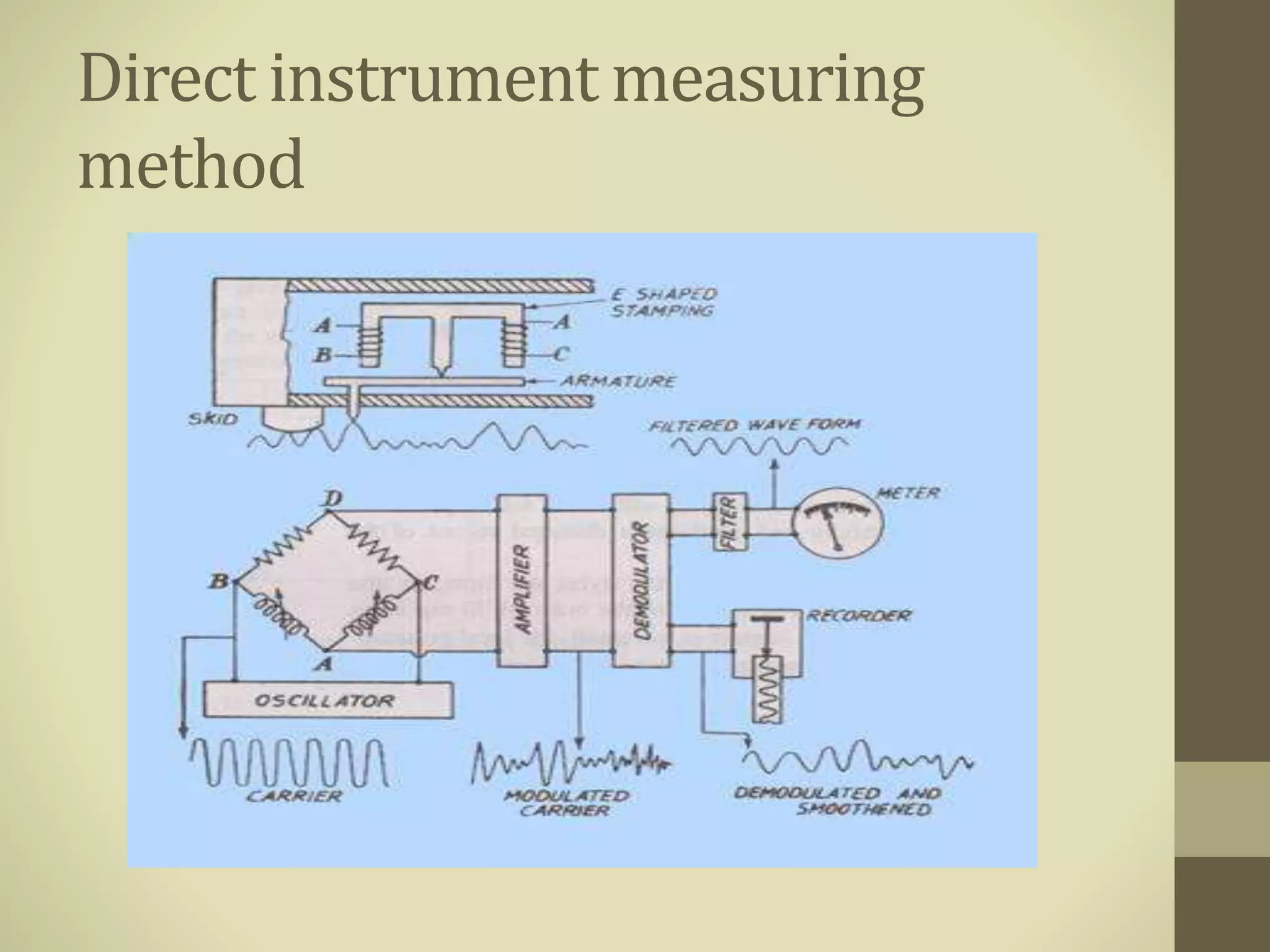

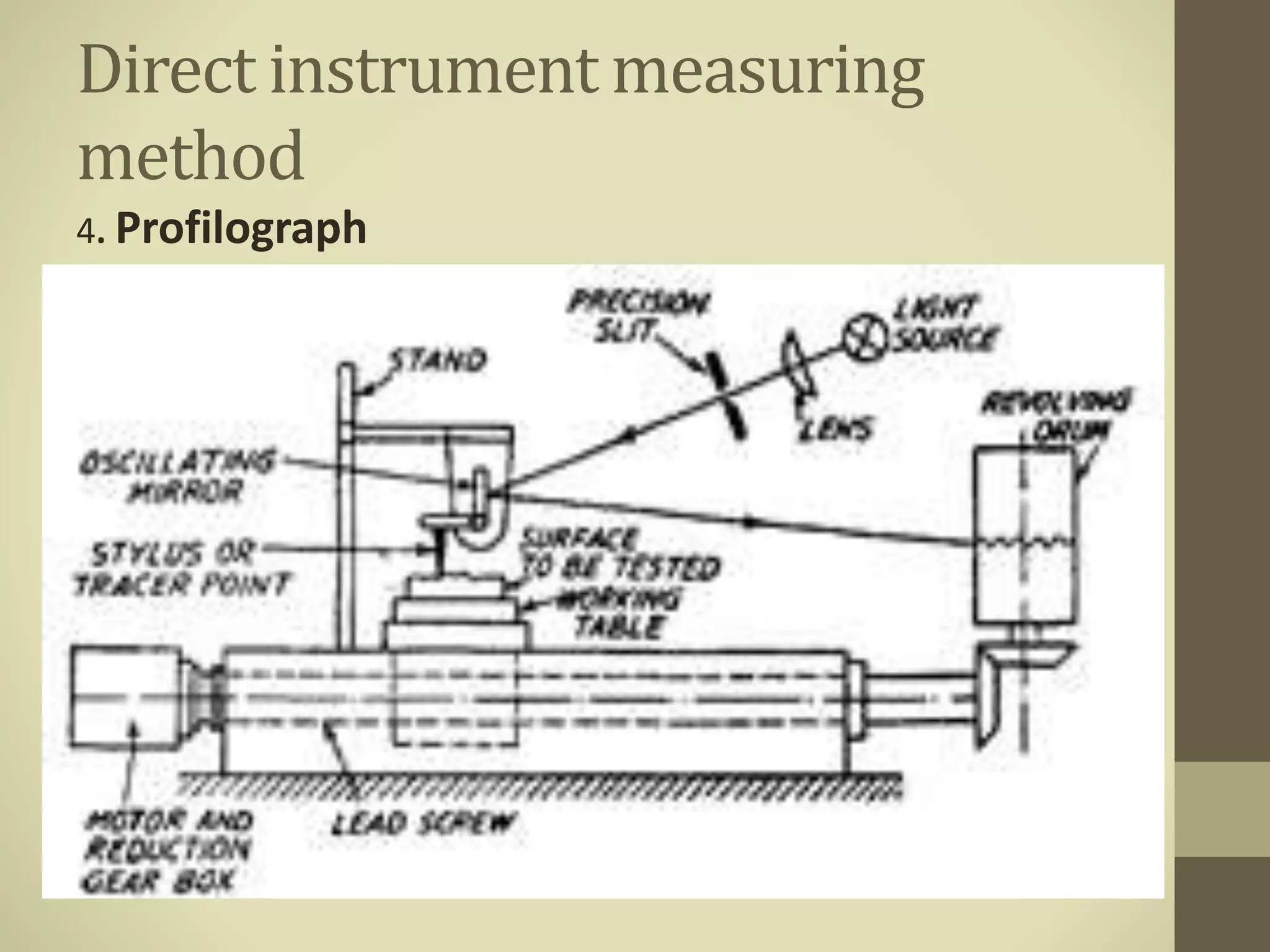

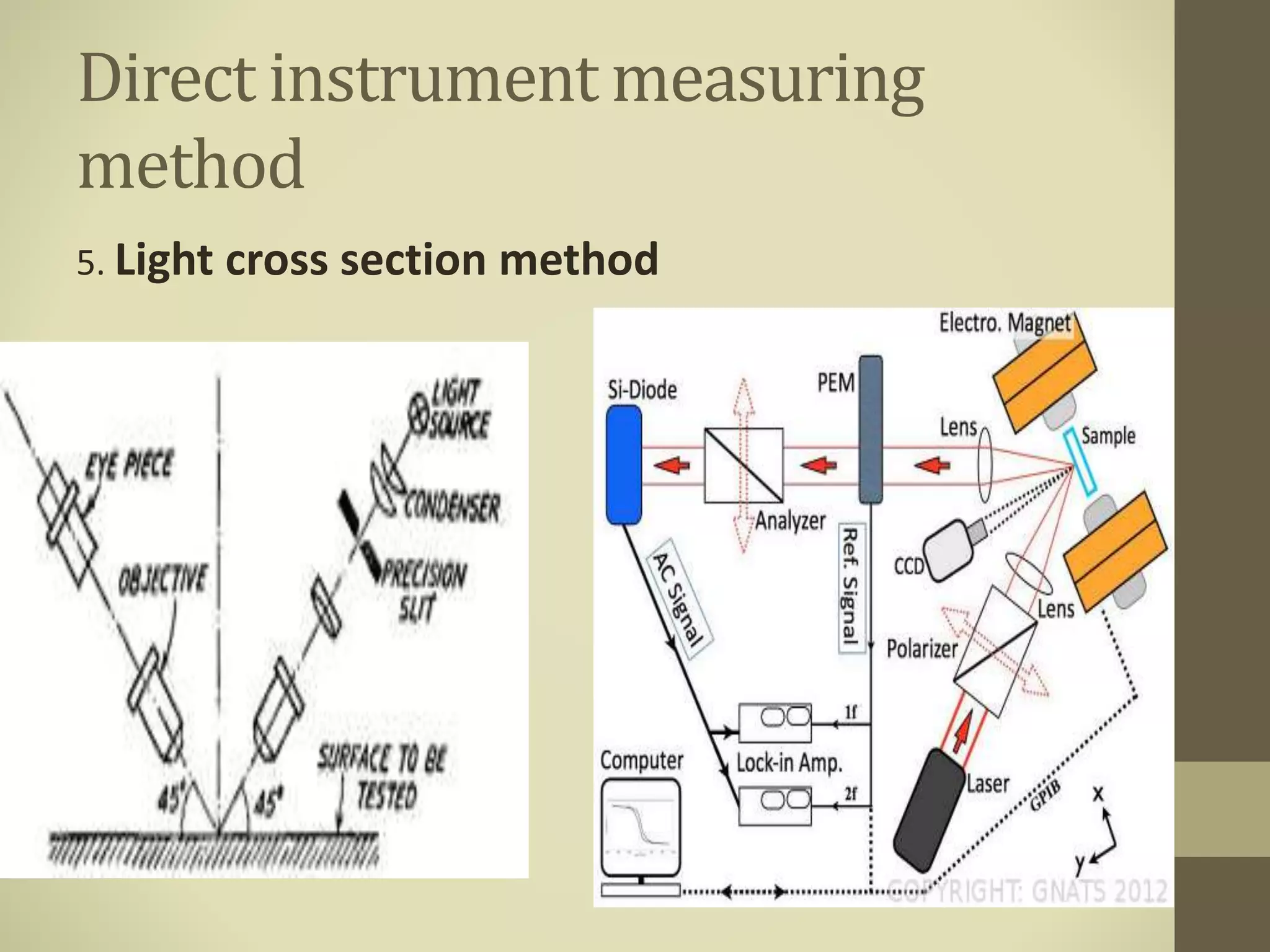

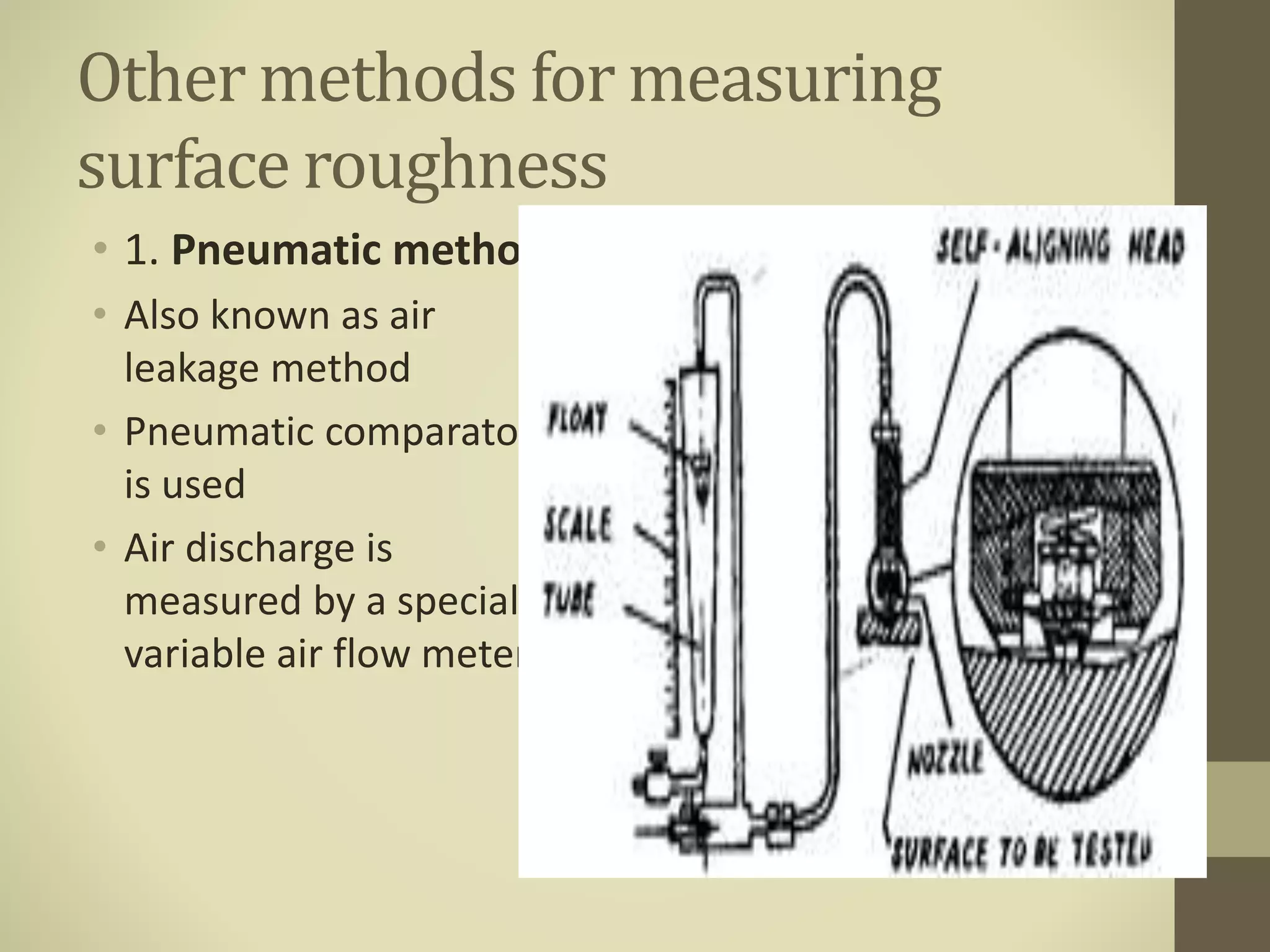

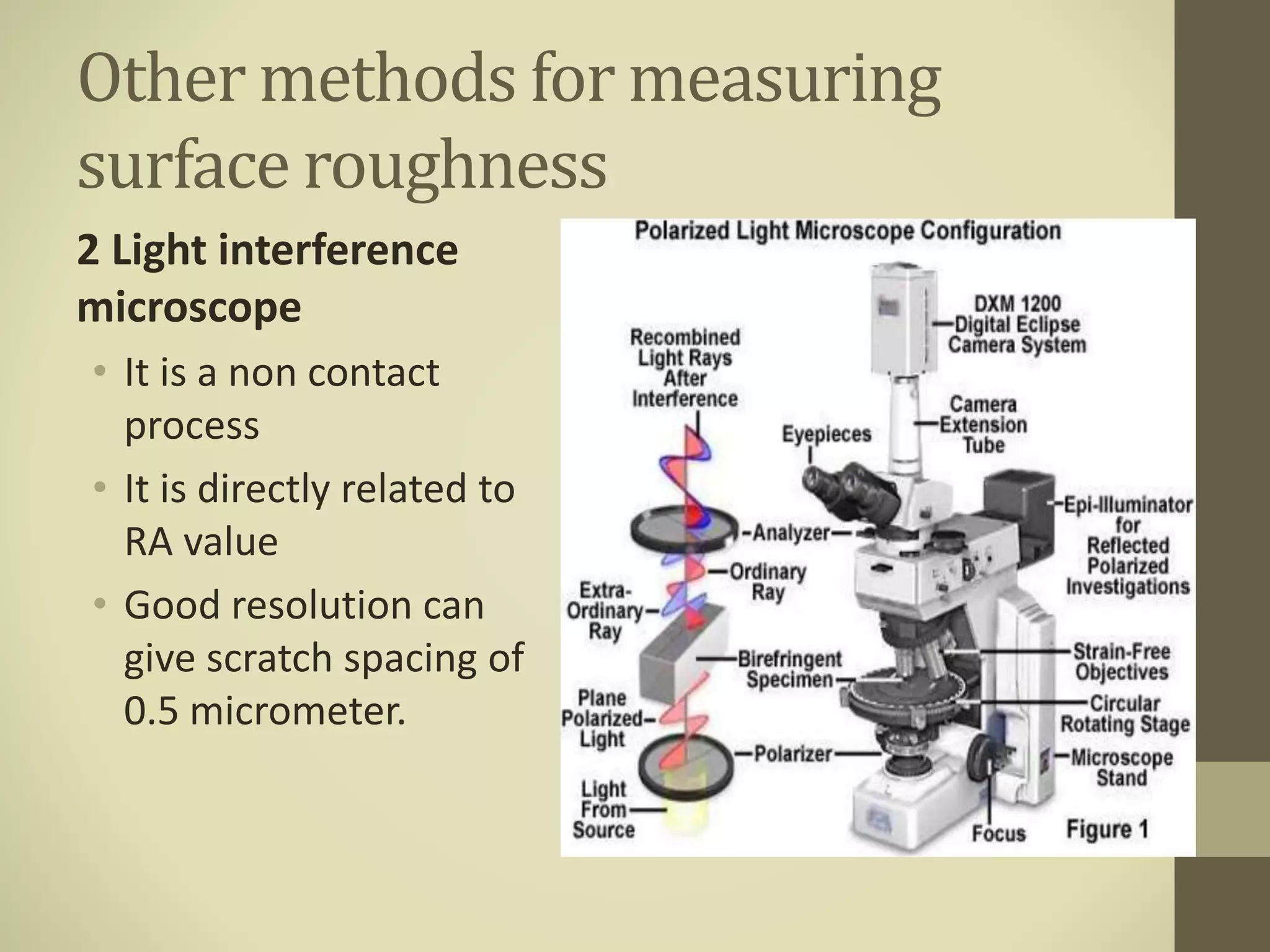

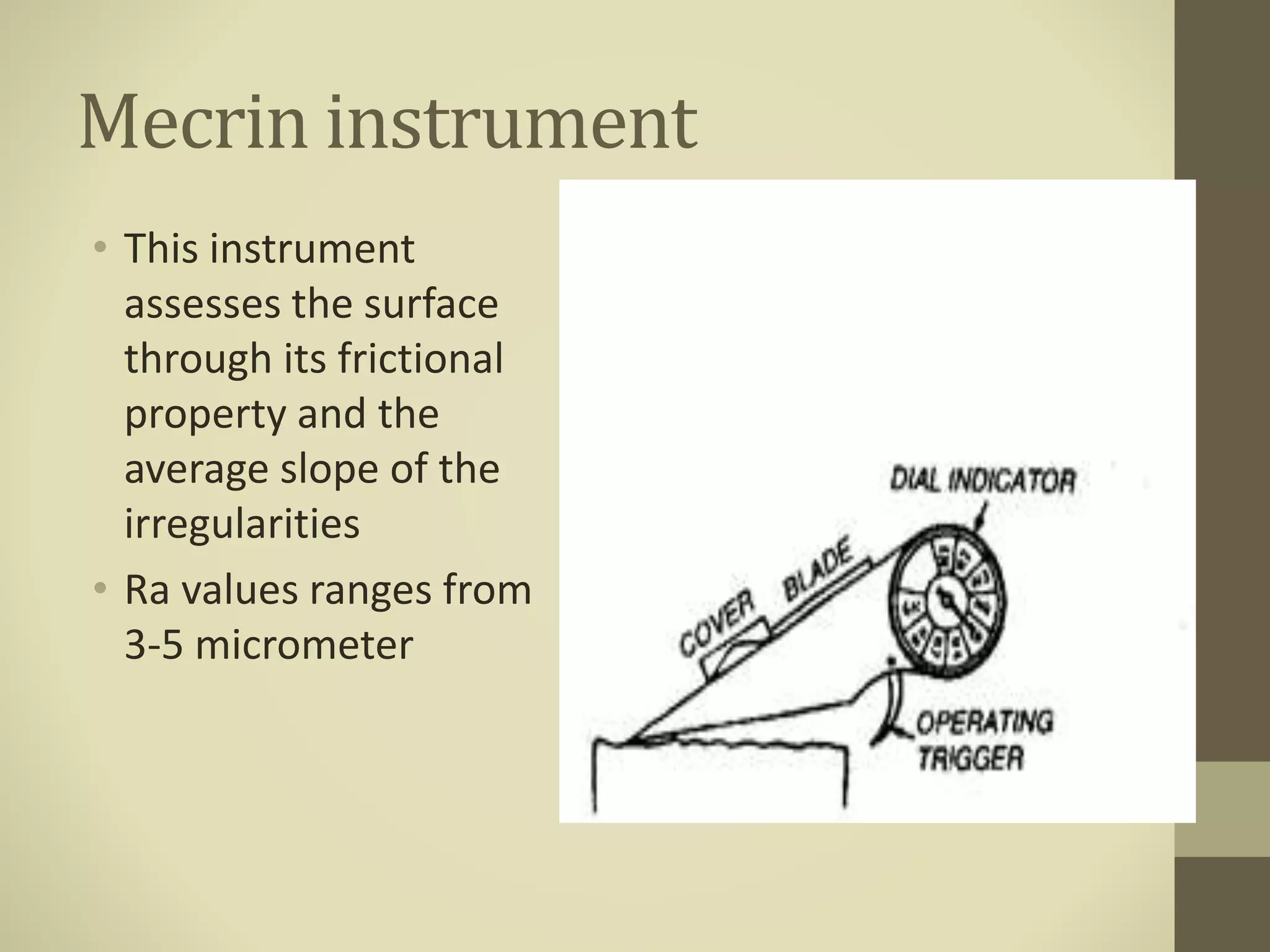

The document provides an overview of surface finish measurement in mechanical measurement and metrology, detailing various classifications of surface texture and terminology. It outlines several methods for measuring surface finish, including comparison, direct instrument measurement, and other techniques, while highlighting the importance of surface finish on fatigue strength, wear resistance, and corrosion resistance. Several instruments and methods, such as profilometers and optical measurement techniques, are described for assessing surface characteristics.