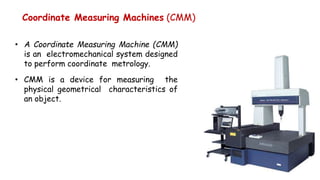

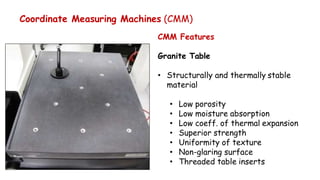

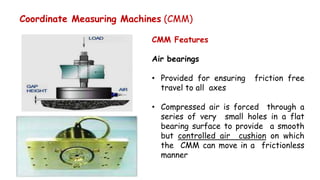

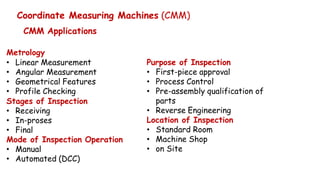

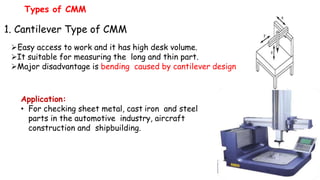

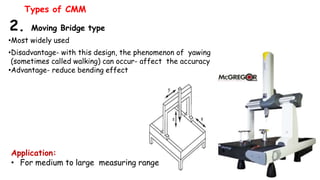

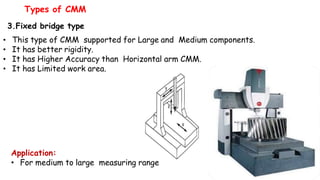

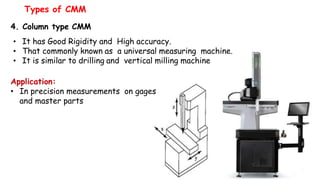

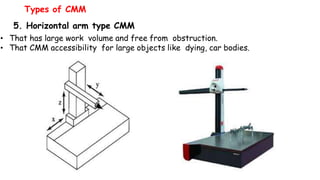

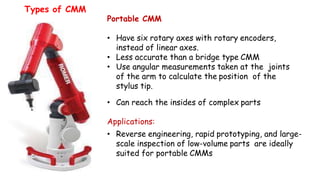

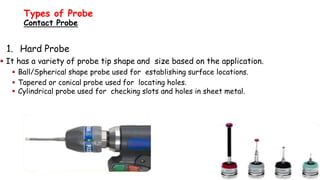

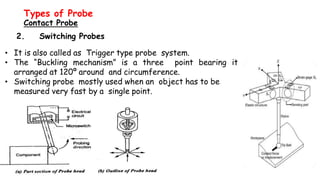

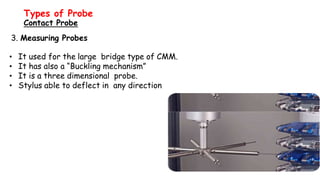

The document discusses Coordinate Measuring Machines (CMM), which are electromechanical systems used for coordinate metrology to measure the physical geometrical characteristics of objects. It outlines the components, types, features, applications of CMM, and probes used, including the potential causes of measurement errors due to alignment, calibration, and environmental factors. Various CMM types, such as cantilever, moving bridge, and gantry, are highlighted for their specific advantages and applications.

![BAHIR DAR UNIVERSITY

BAHIR DAR INSTITUTE OF TECHNOLOGY (BiT)

FACULTY OF MECHANICAL AND INDUSTRIAL

ENGINEERING

Rapid Prototyping & Reverse Engineering

[MEng6123]

Reverse Engineering

Coordinate Measuring Machine (CMM)](https://image.slidesharecdn.com/lecture09-201226203103/75/Lecture-09-Coordinate-Measuring-Machine-CMM-1-2048.jpg)