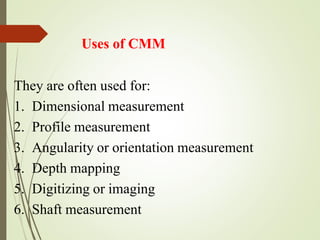

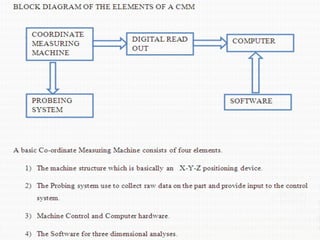

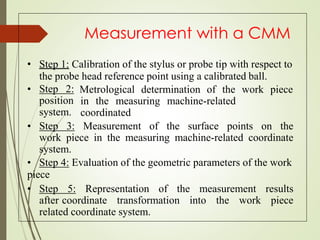

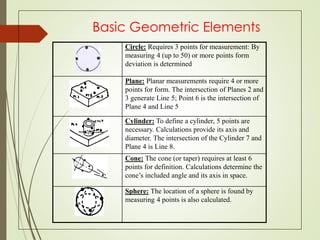

- A coordinate measuring machine (CMM) uses probes to inspect physical objects and measure their geometric features based on a coordinate system.

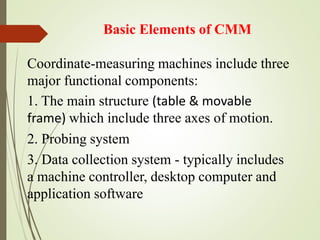

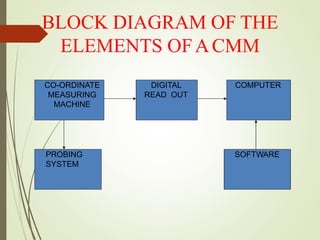

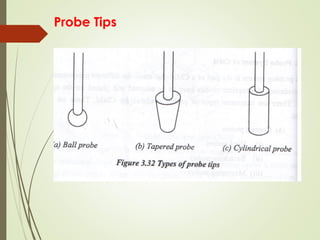

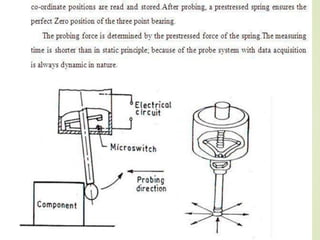

- CMMs can be manually operated or computer controlled, and use probes attached to movable axes to collect 3D coordinate data on measured points.

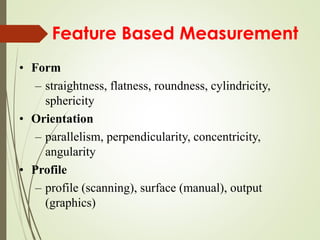

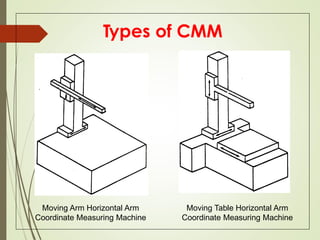

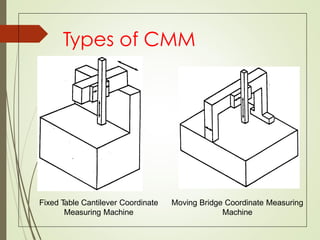

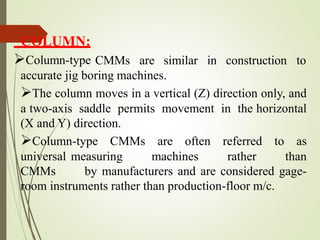

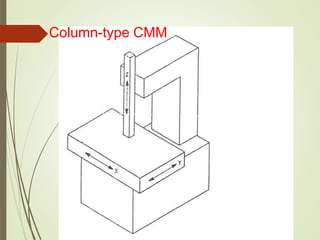

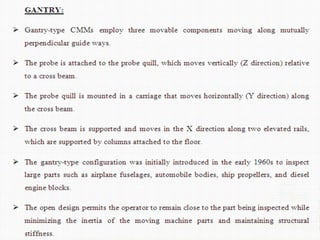

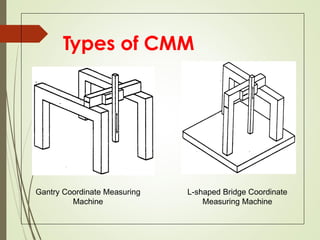

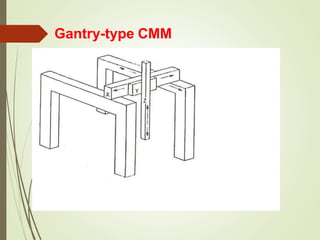

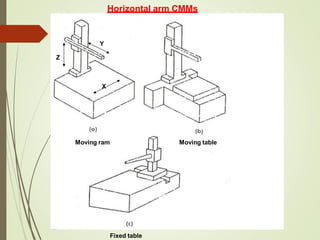

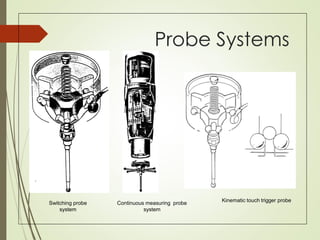

- Common CMM configurations include bridge, column, gantry, and horizontal arm styles, with probes that can be mechanical, optical, laser, or white light. CMMs provide highly accurate measurements in microns or micrometers.