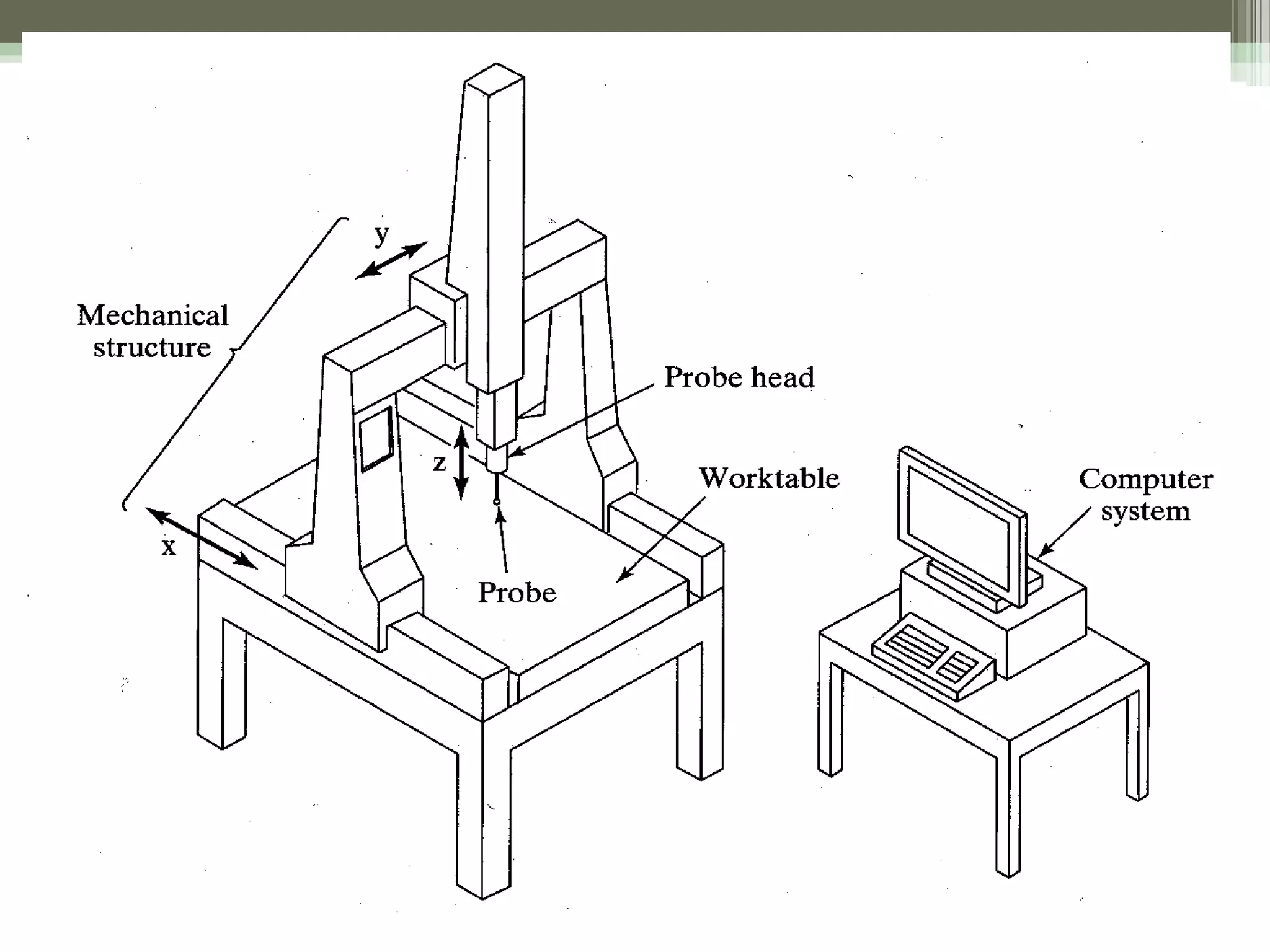

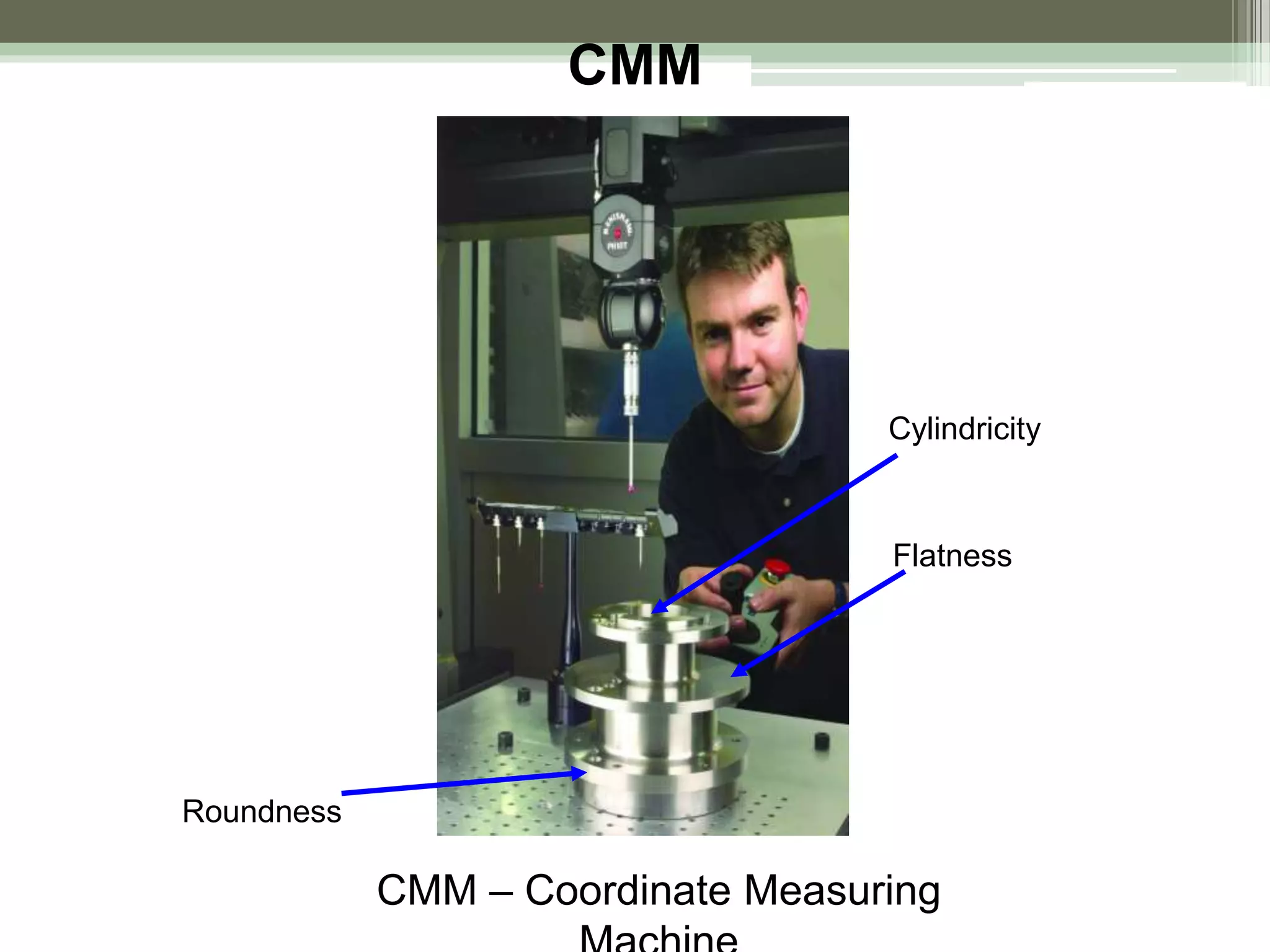

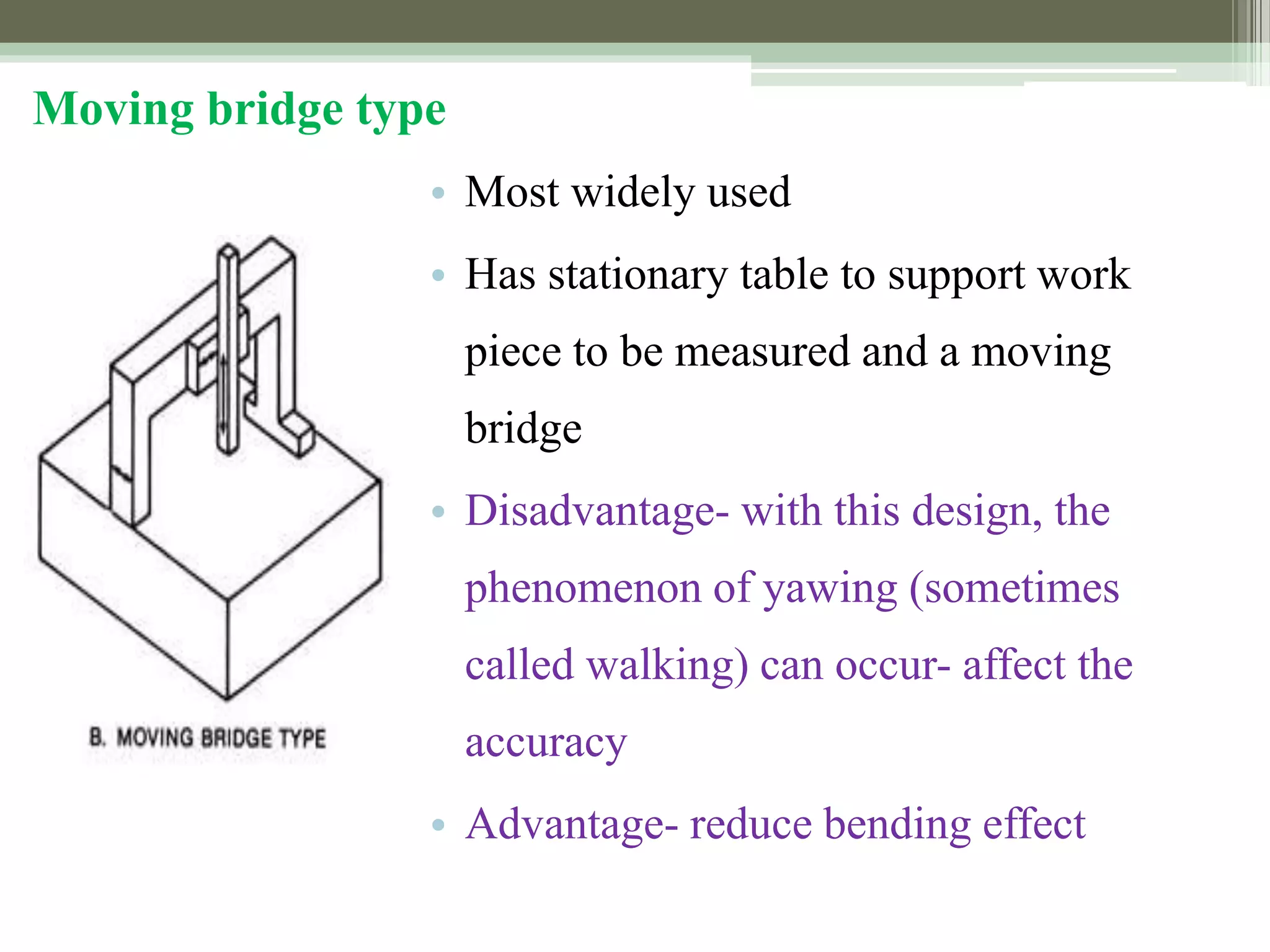

The document discusses coordinate measuring machines (CMMs). A CMM consists of a probe that can be positioned accurately in three dimensions relative to a workpiece surface. The probe's coordinates are recorded to obtain dimensional data about the workpiece's geometry. Different CMM structures are described, including cantilever, moving bridge, fixed bridge, horizontal arm, column, and gantry designs. CMMs offer advantages like increased inspection speed and accuracy compared to manual inspection. They find applications in industries like automotive, aerospace, electronics, and machining for quality control and inspection of parts and tools.