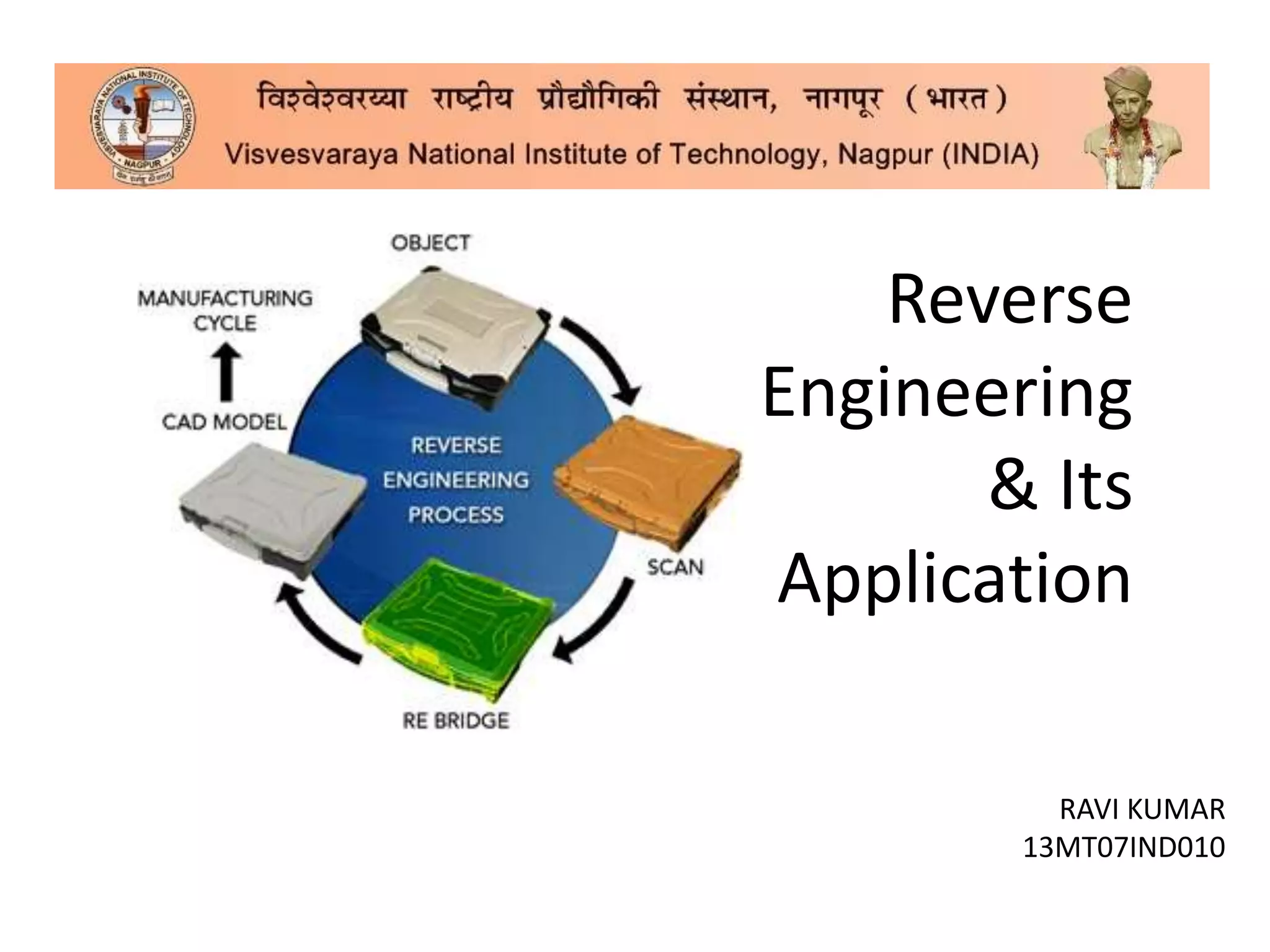

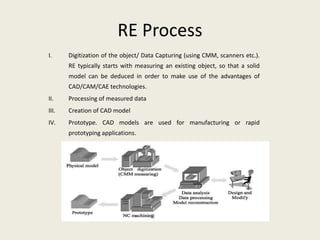

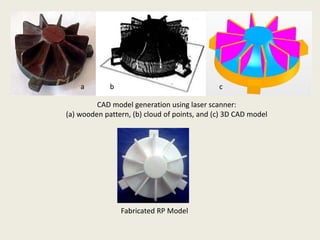

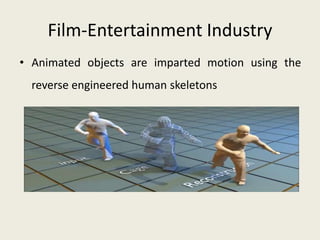

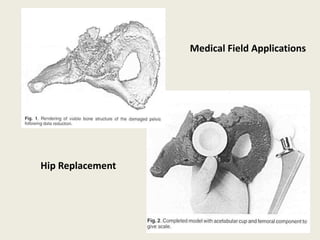

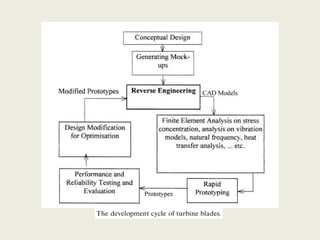

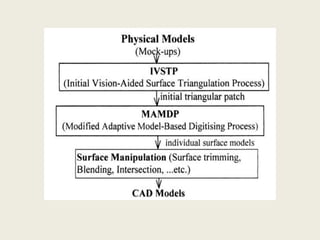

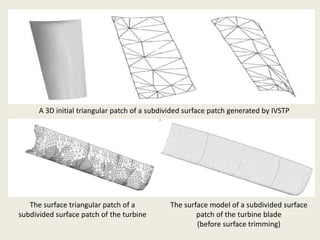

This document discusses reverse engineering and its application. It begins by defining reverse engineering as the systematic evaluation of a product to replicate, copy, or recover parts. Reverse engineering is important in product development by allowing optimization of existing resources and reducing development time. The document then provides an example of using reverse engineering to analyze why an impeller pump's performance degraded over time. It outlines the advantages and process of reverse engineering, as well as applications in various fields like manufacturing, software, chemical, film, and medical engineering. A case study describes how reverse engineering was used to design turbine blades by overcoming issues in existing digitization processes.