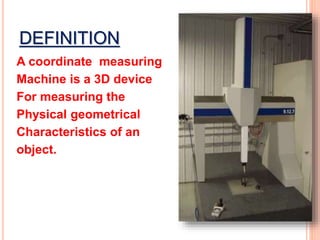

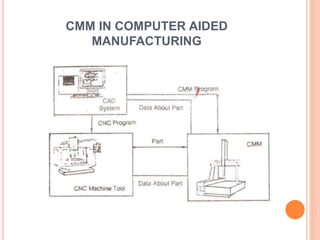

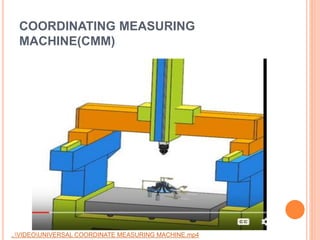

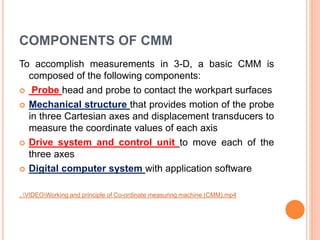

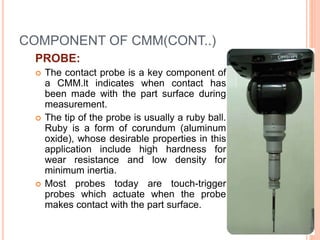

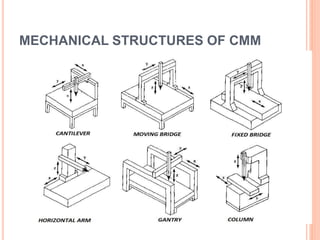

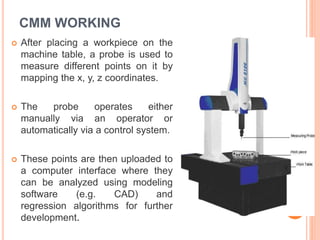

A coordinate measuring machine (CMM) is an electromechanical system used to measure the physical geometrical characteristics of objects with high precision. These machines have three orthogonal axes and utilize a probe to determine size and position by recording X, Y, and Z coordinates. CMMs come in various mechanical structures, including cantilever, moving bridge, and gantry types, and are essential in computer-aided manufacturing for analyzing measurement data.