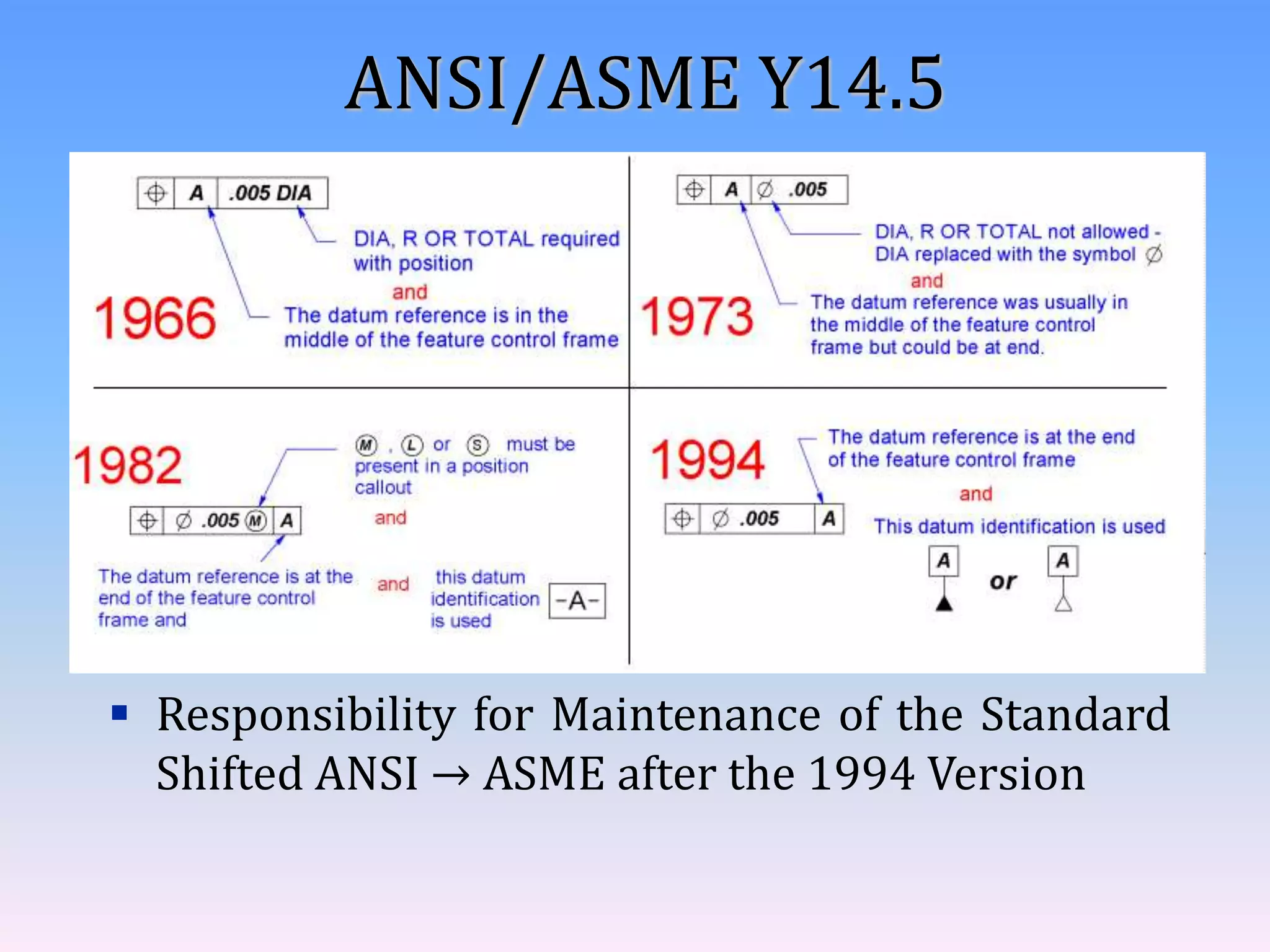

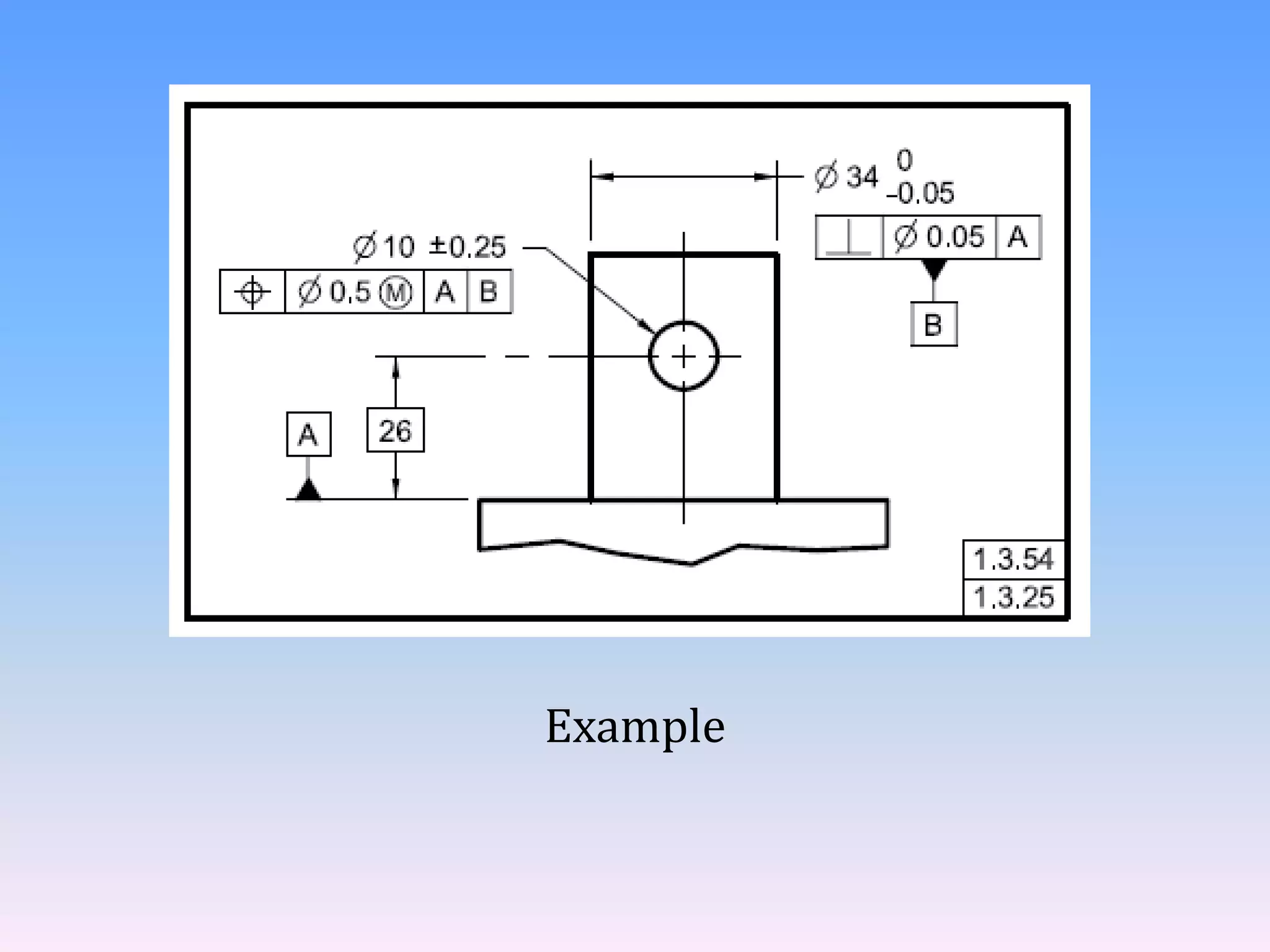

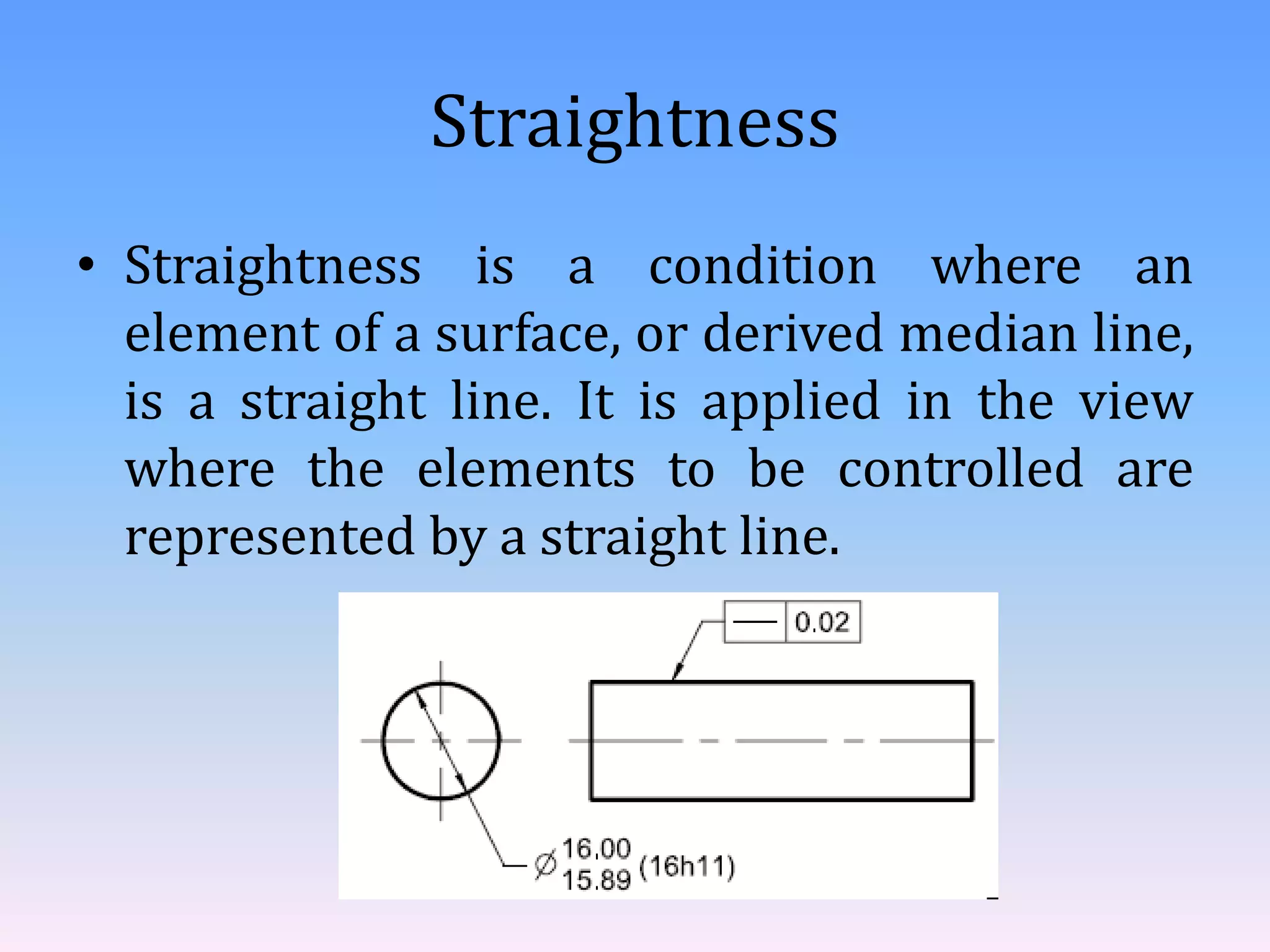

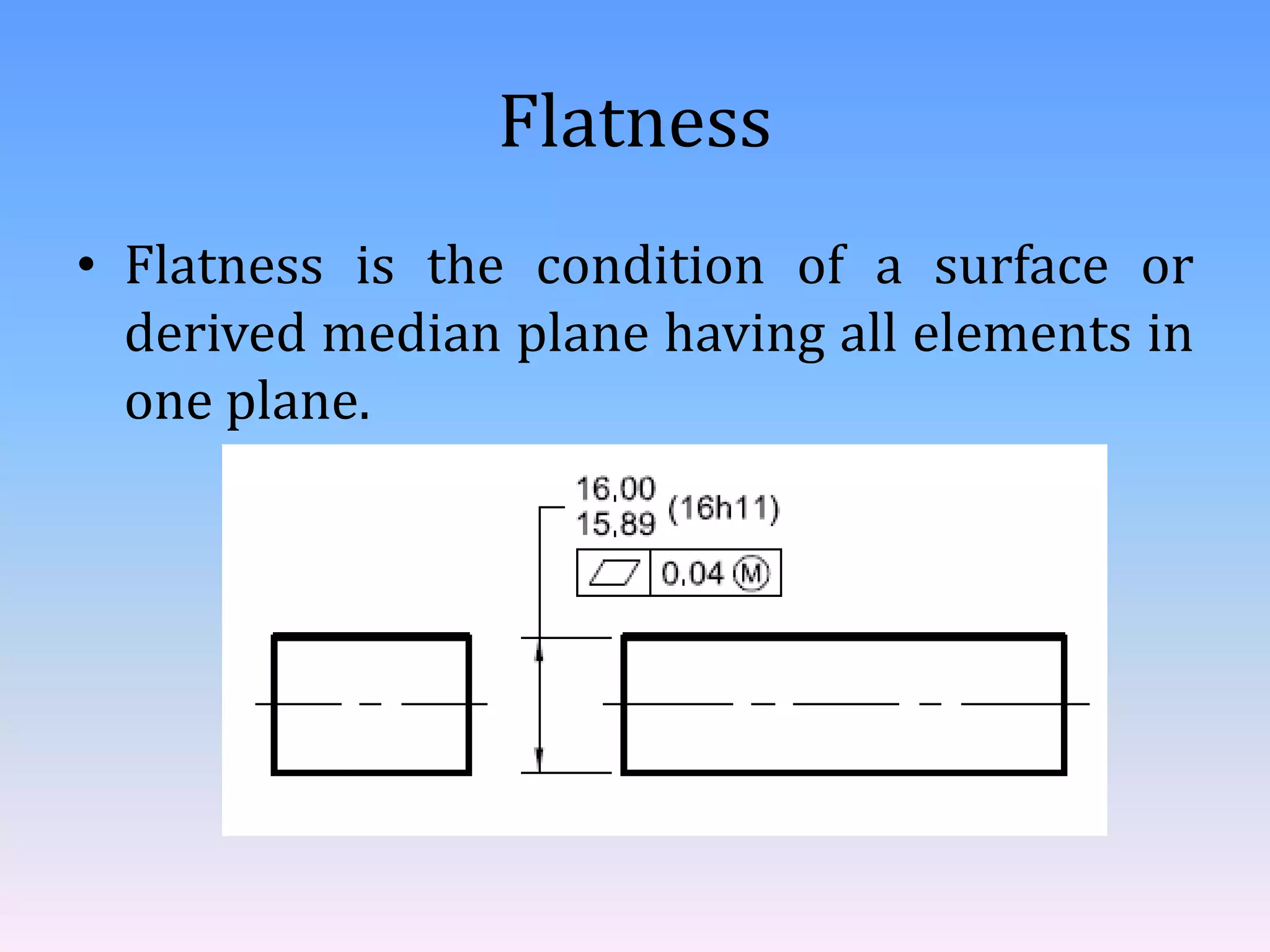

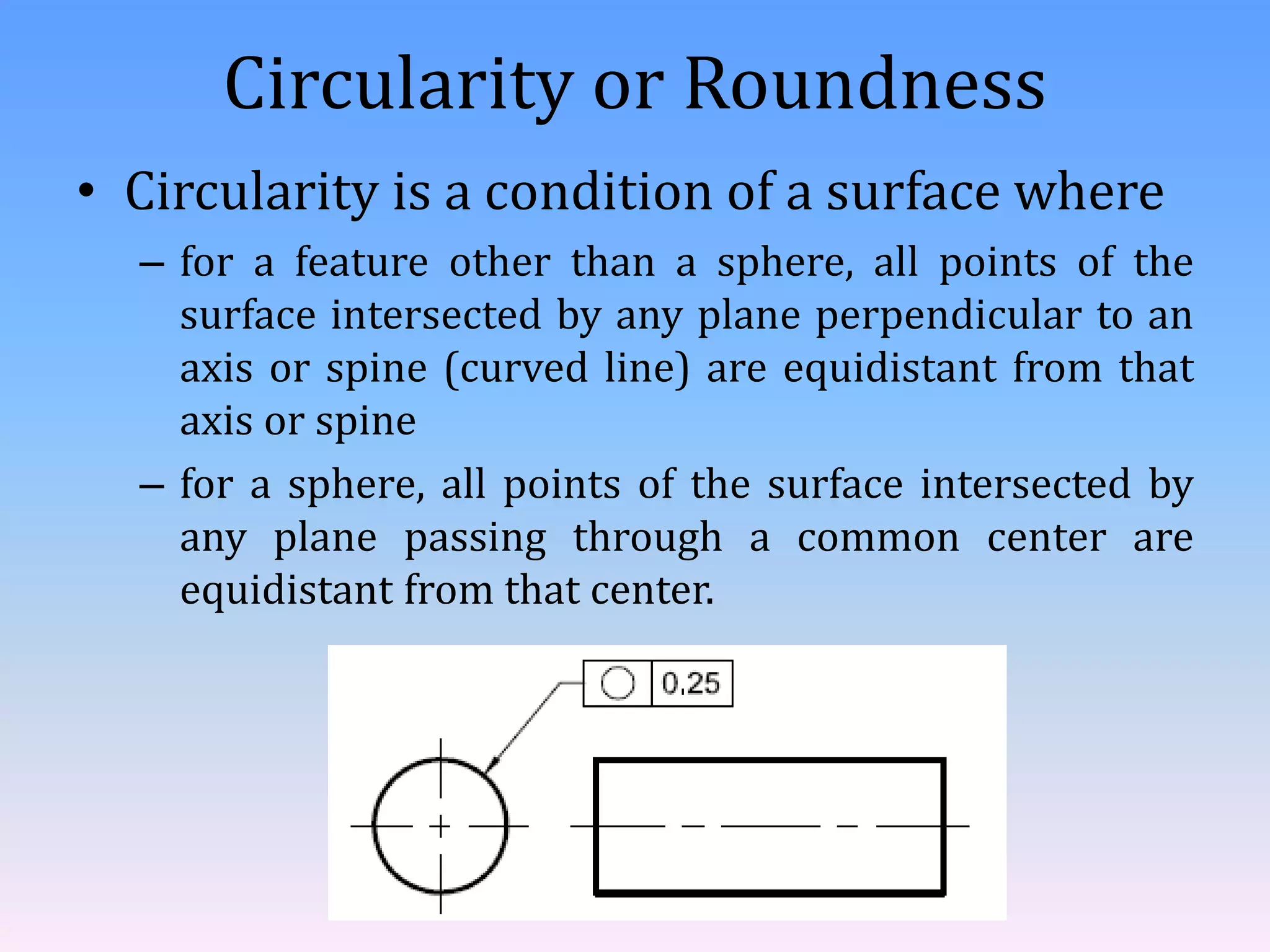

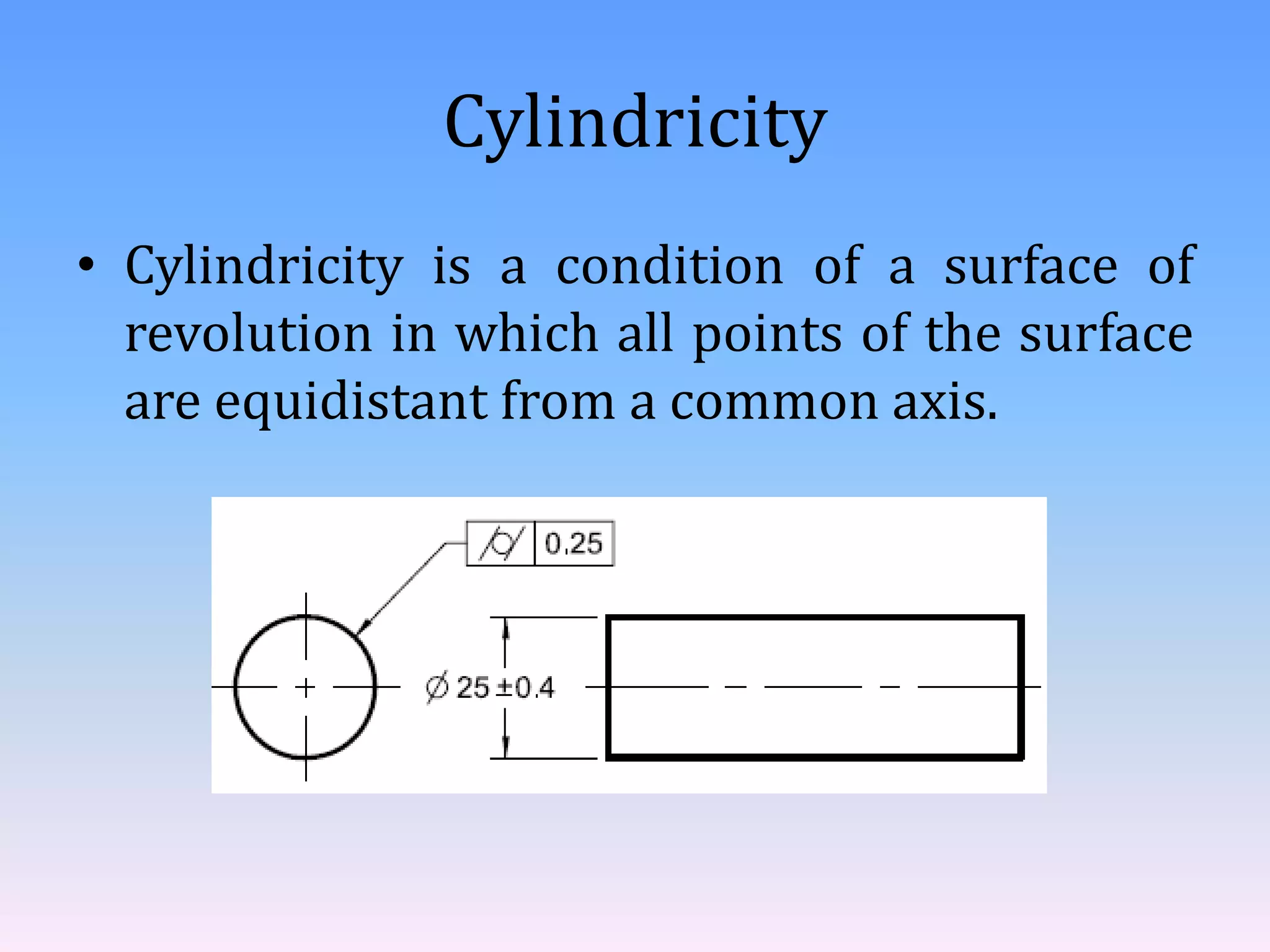

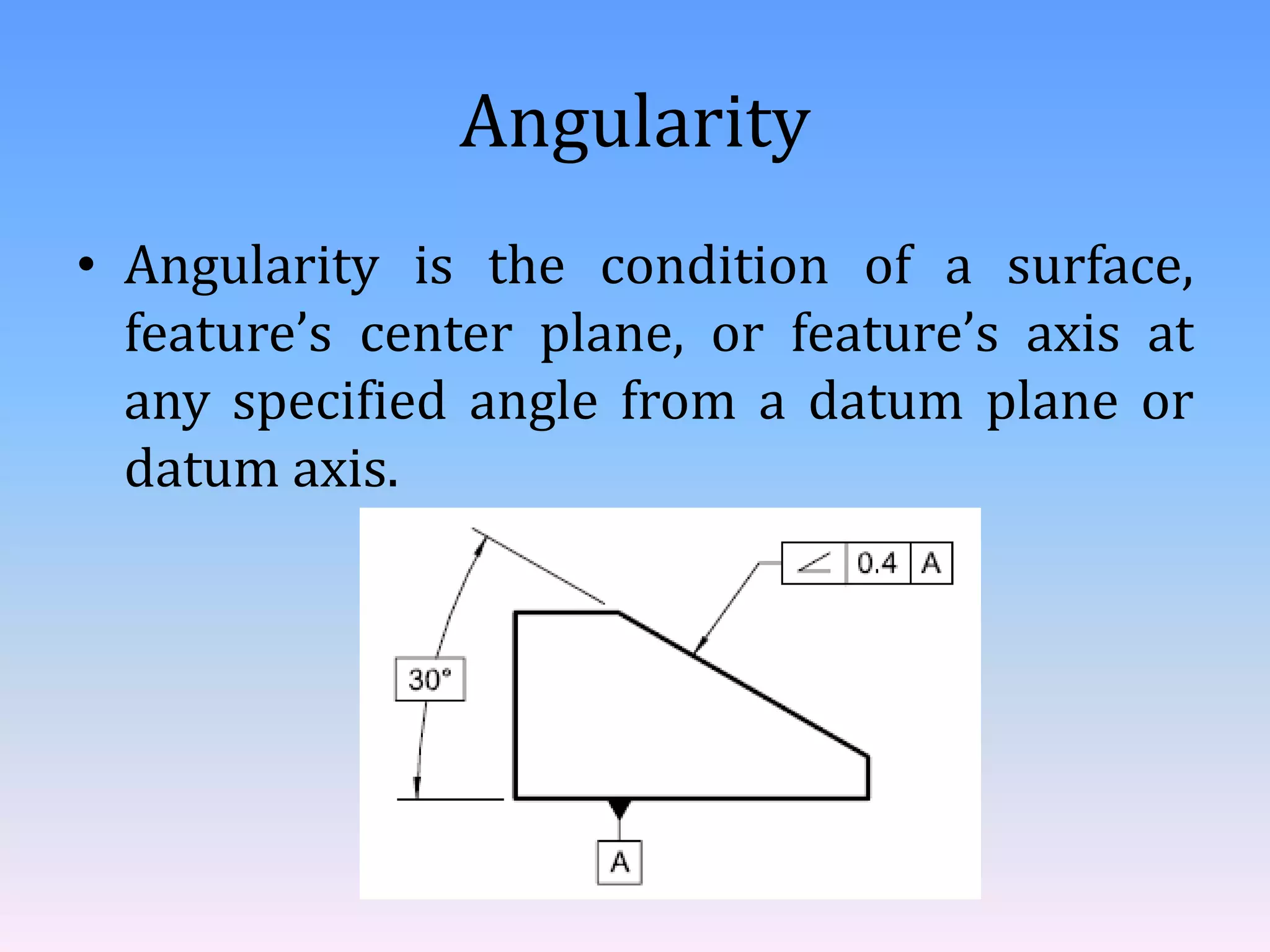

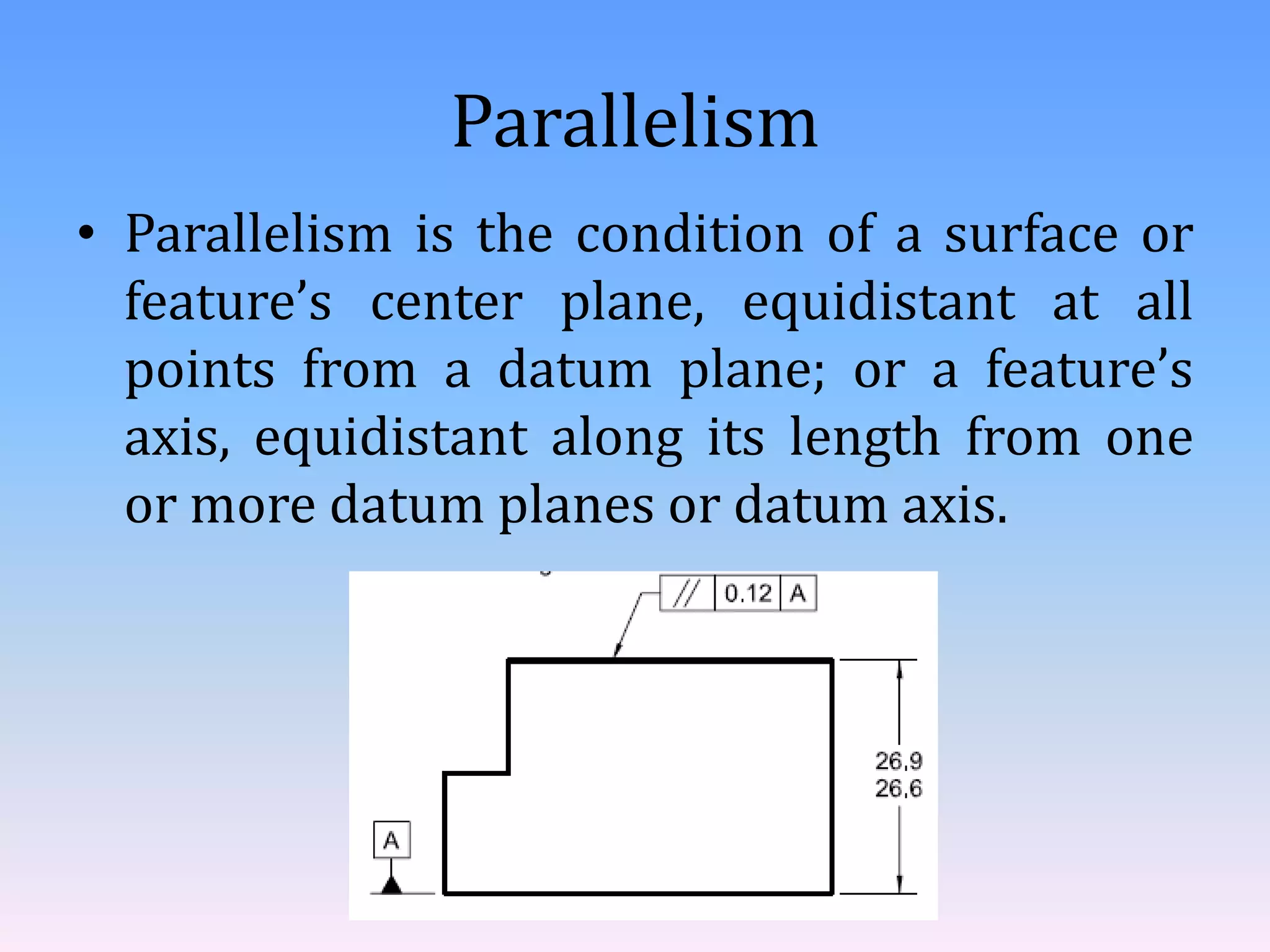

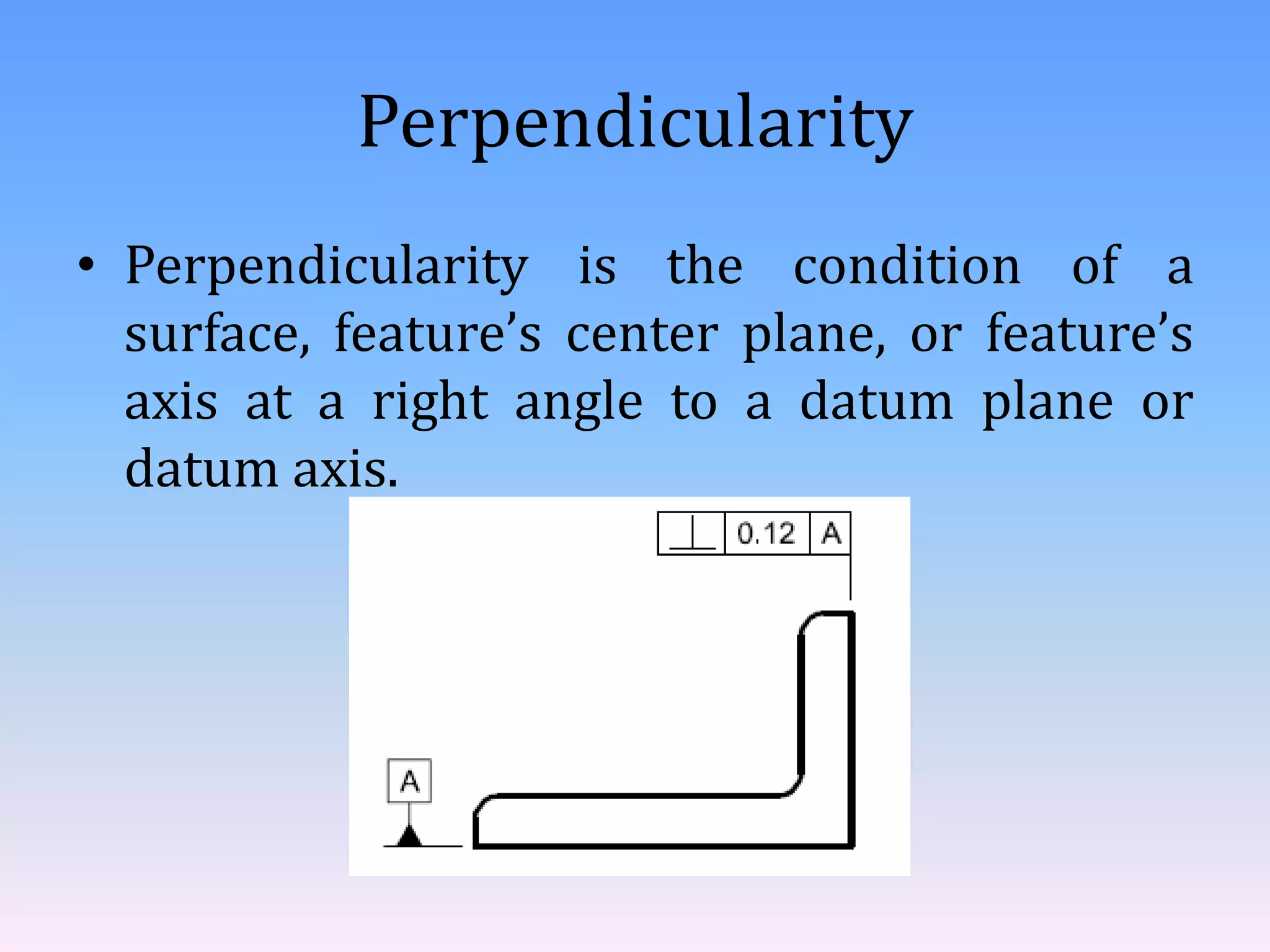

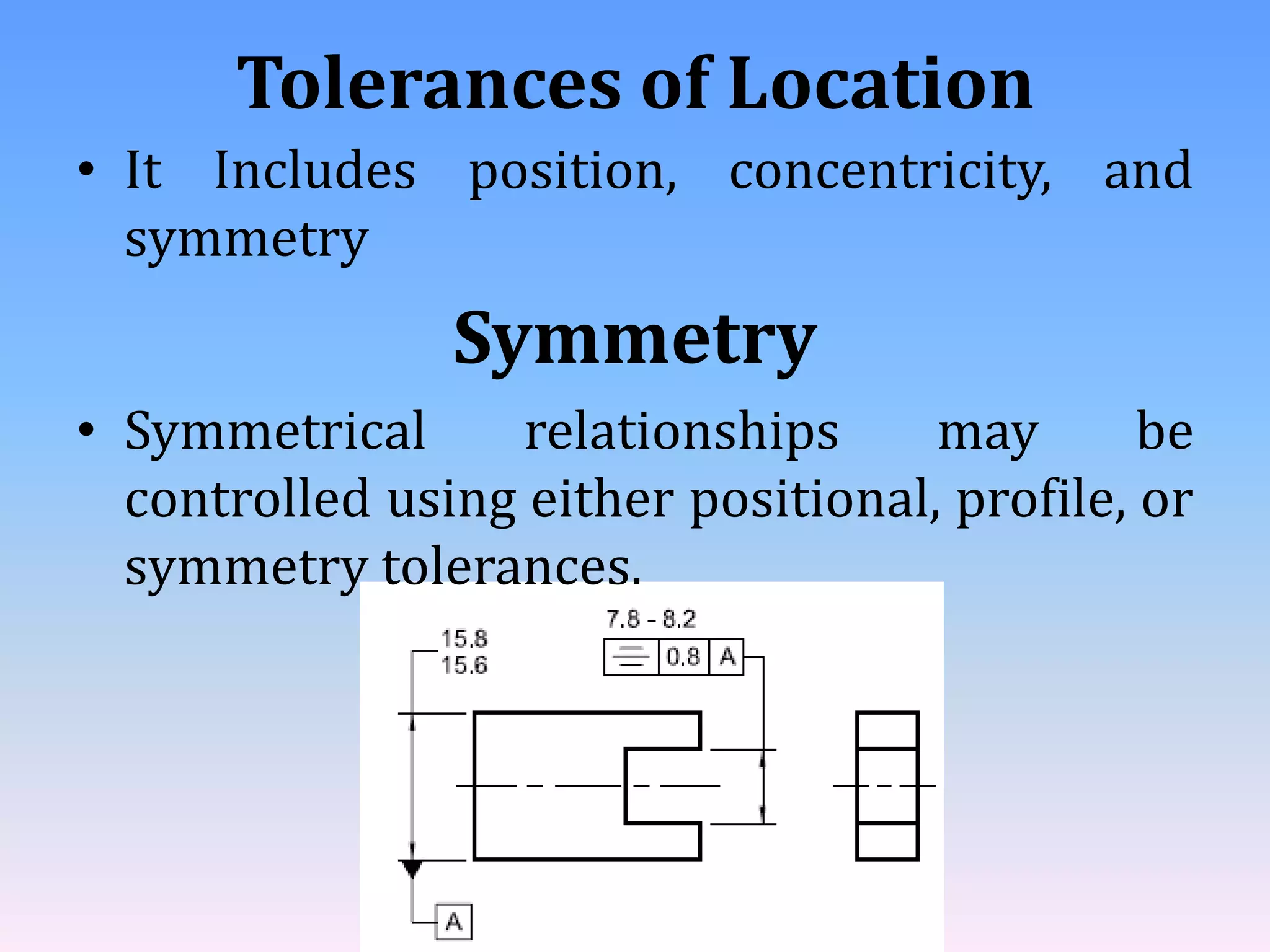

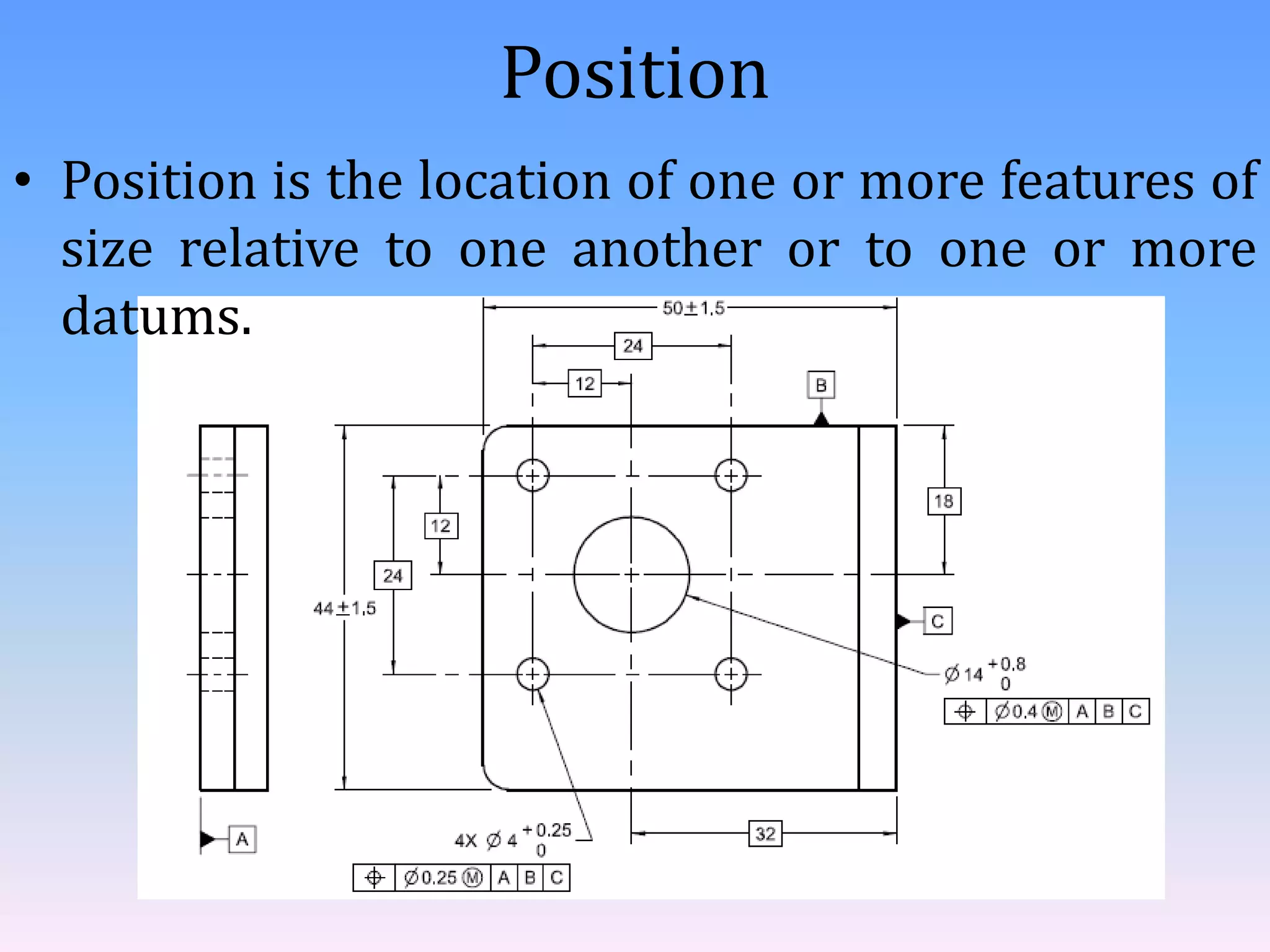

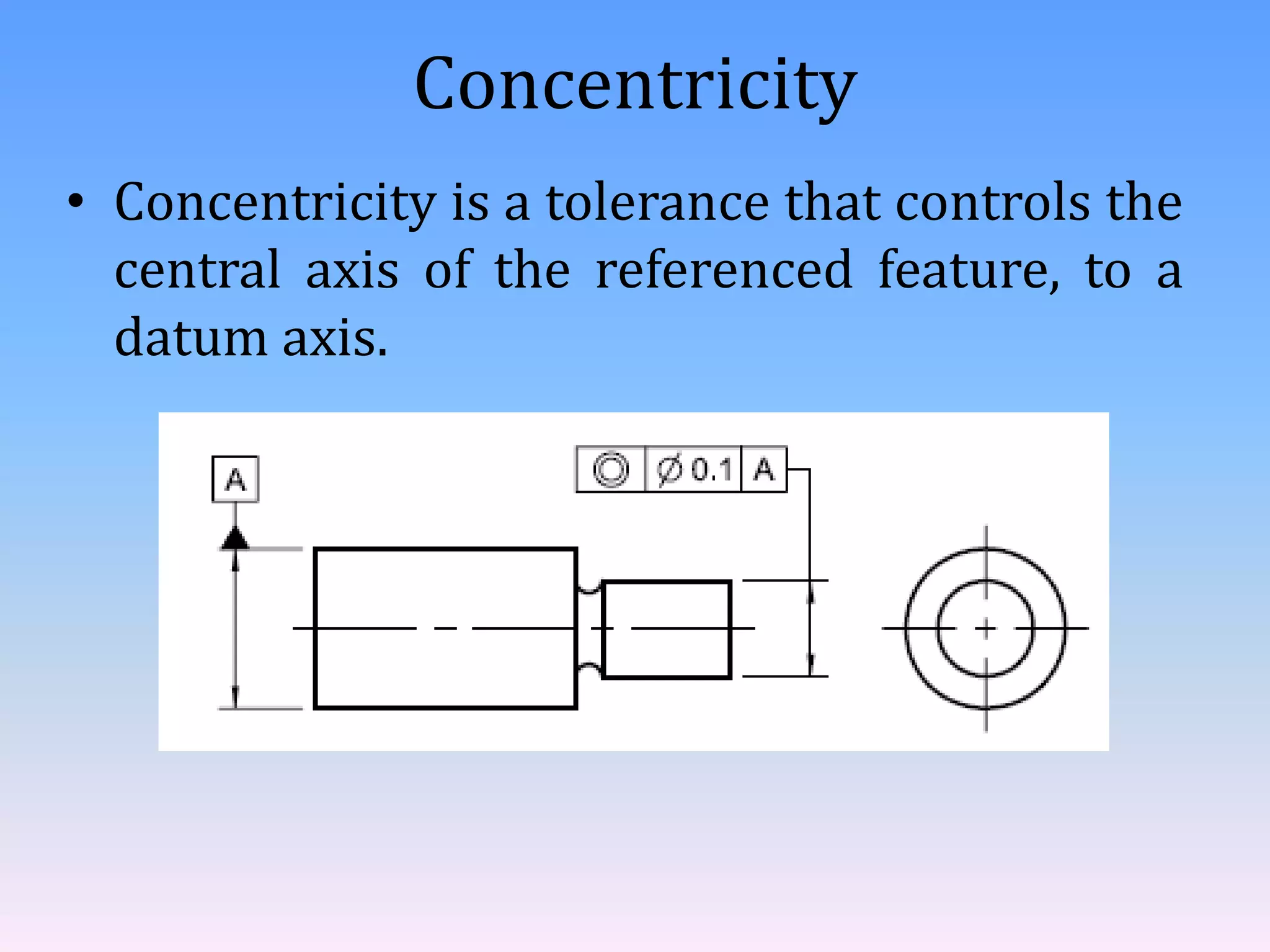

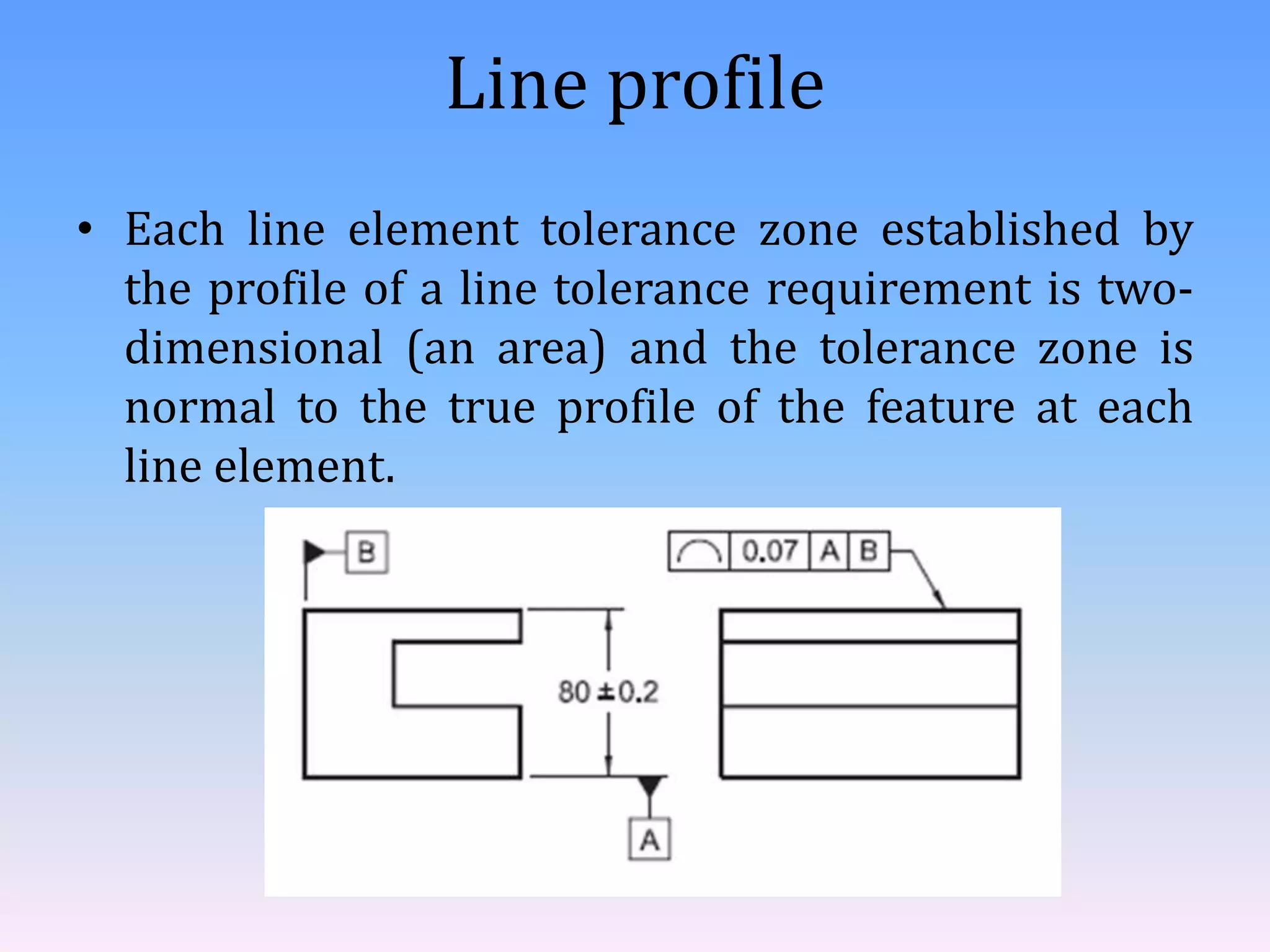

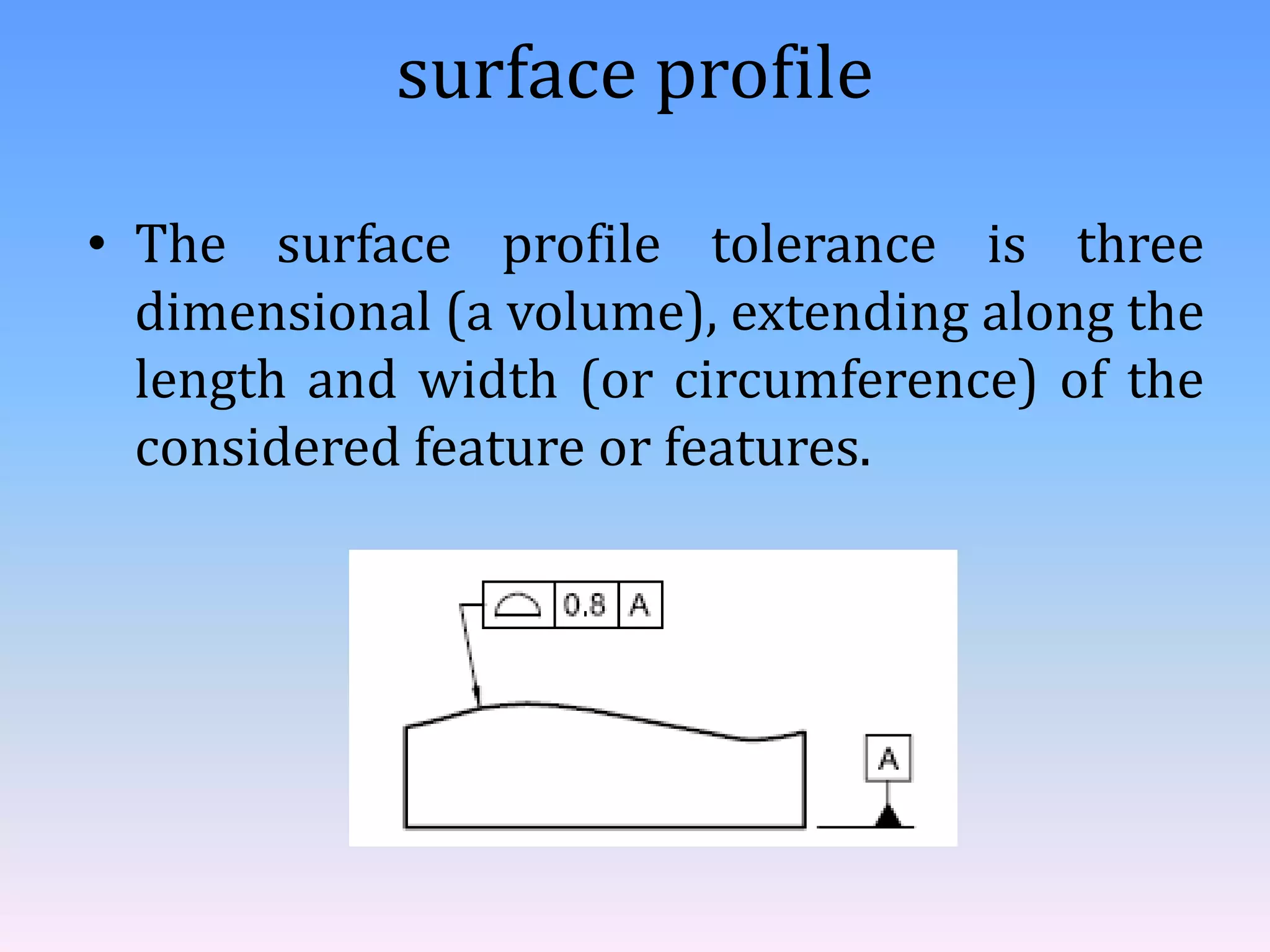

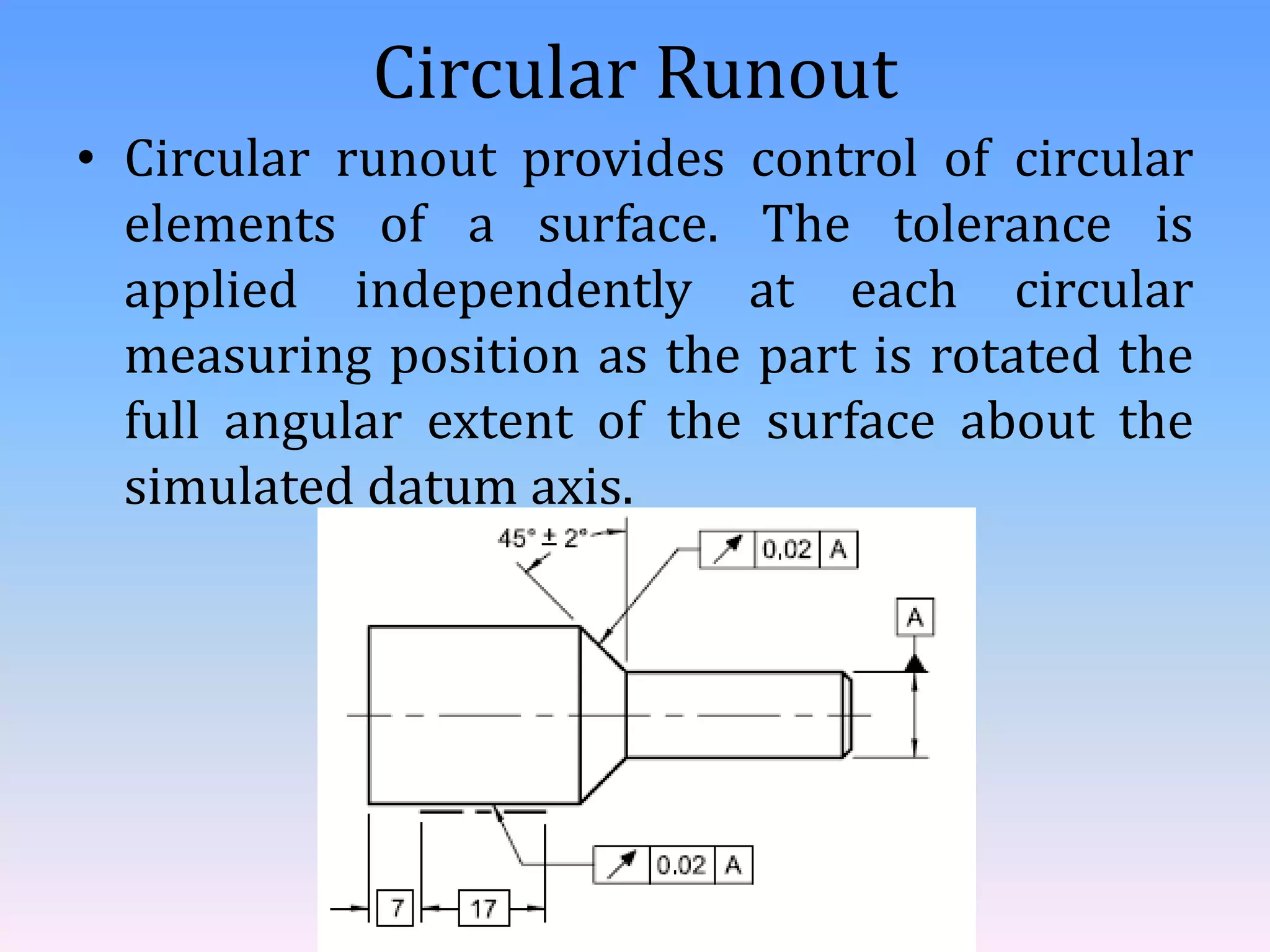

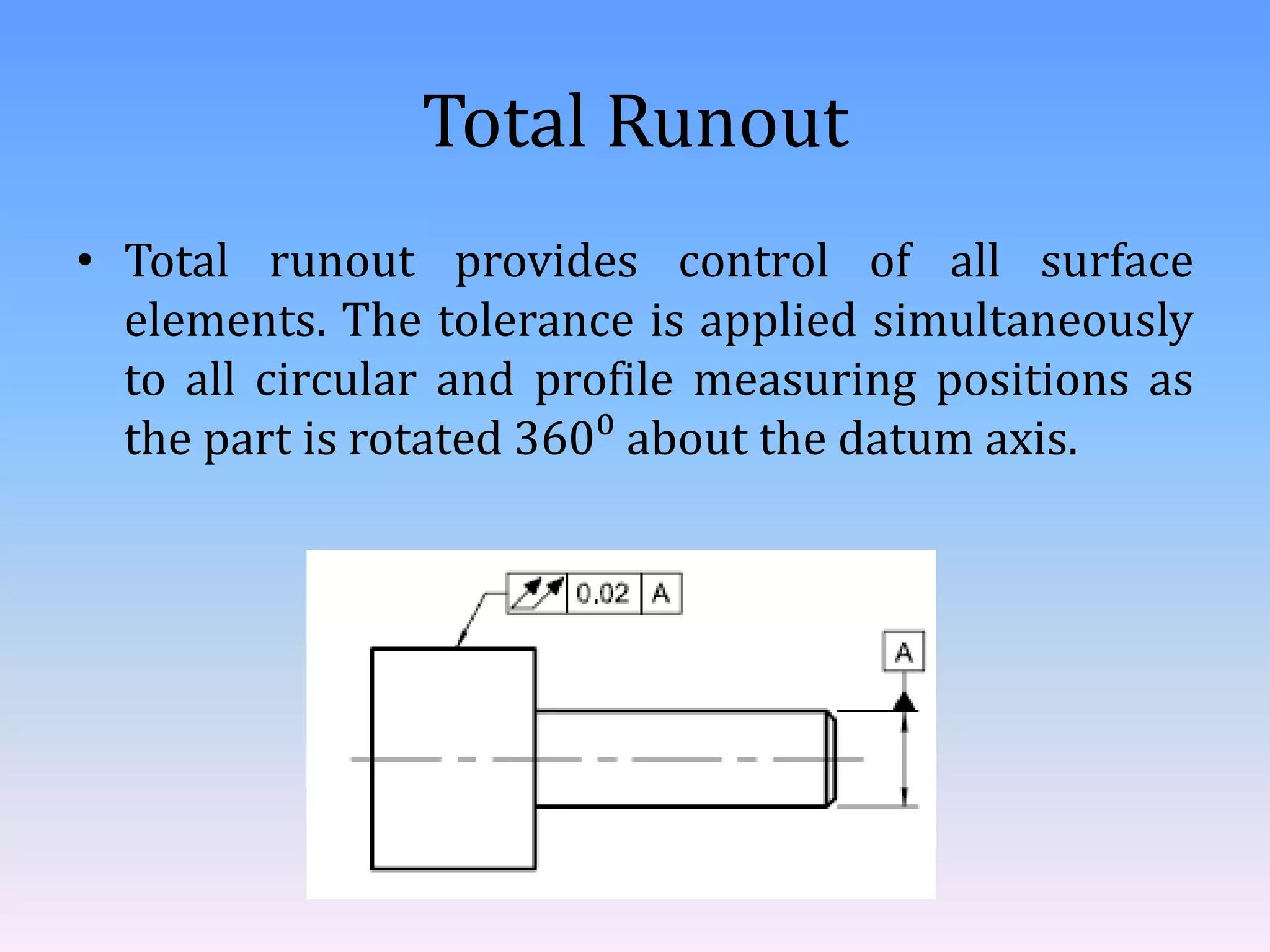

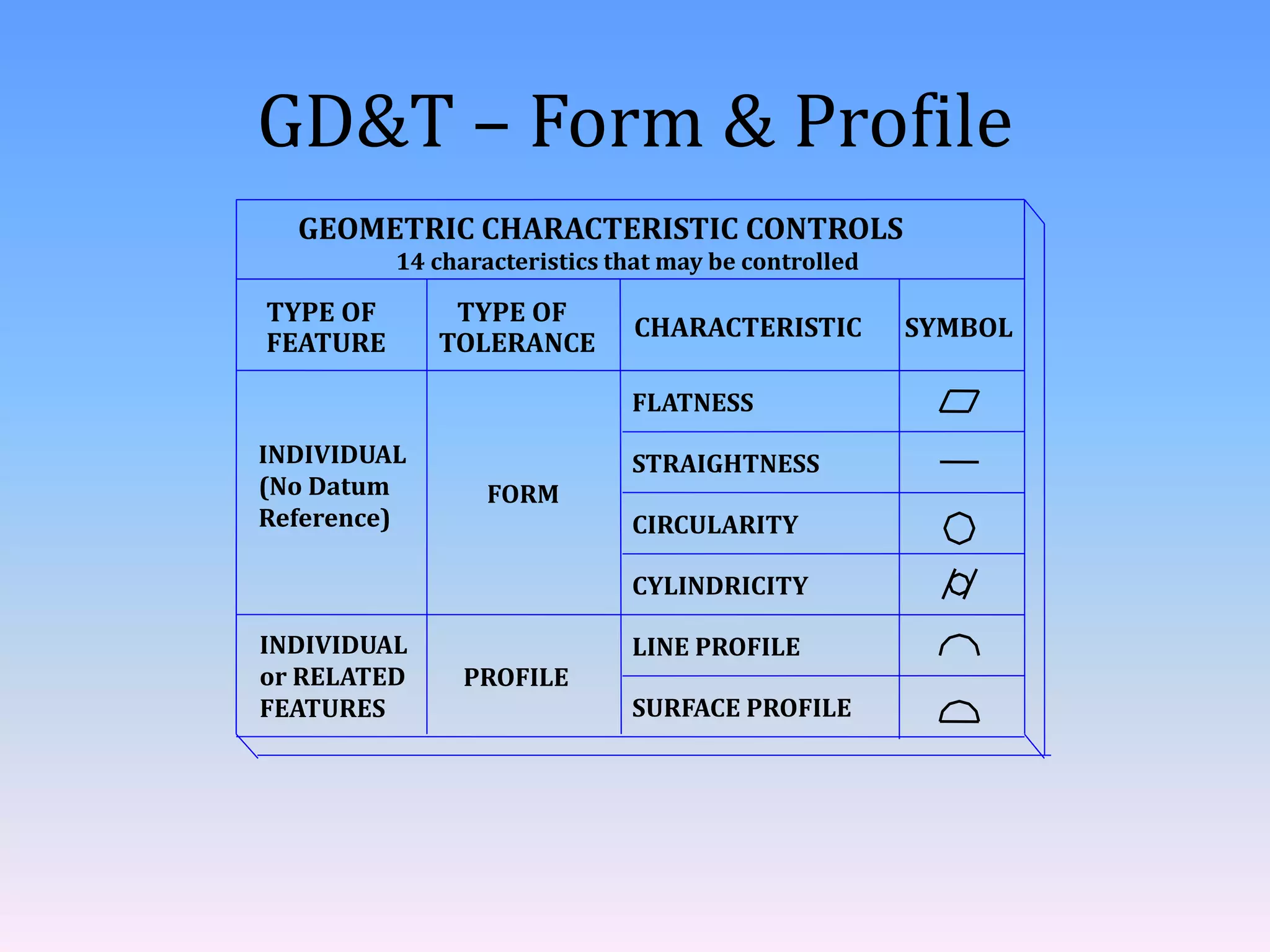

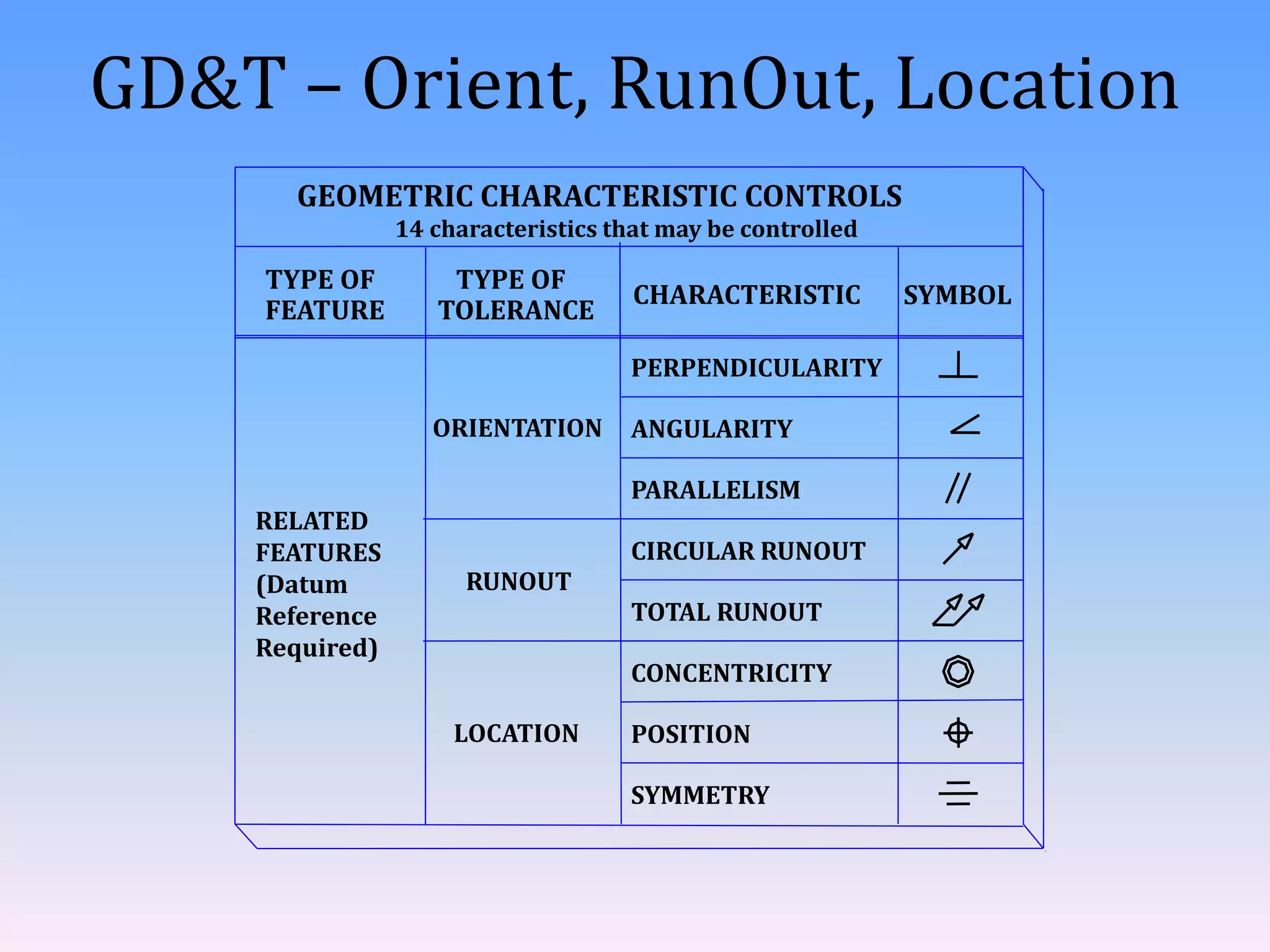

This document discusses Geometric Dimensioning and Tolerance (GD&T) standards. It introduces ASME Y14.5-2009, the authoritative guideline for GD&T design language published by the American Society of Mechanical Engineers. GD&T can control 14 geometric characteristics including form, profile, orientation, runout, and location through standards like straightness, flatness, circularity, position, and concentricity. Form and profile tolerances apply to individual or related features, while orientation, runout, and location tolerances require reference to a datum and relate multiple features.