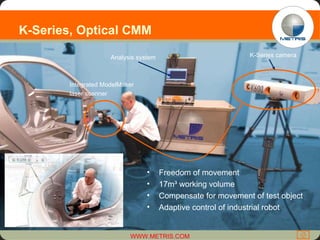

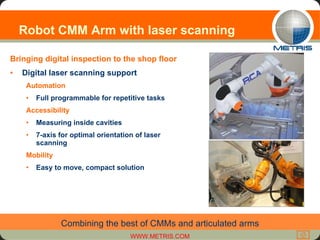

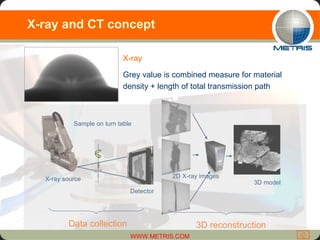

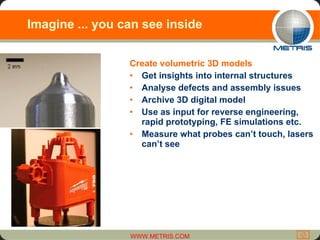

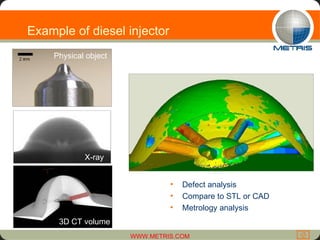

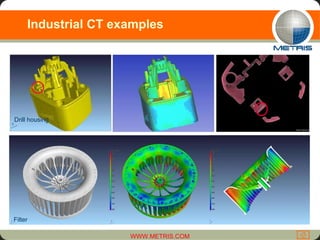

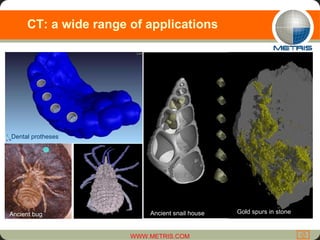

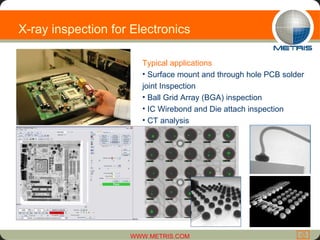

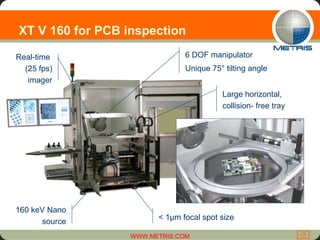

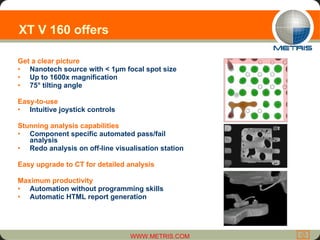

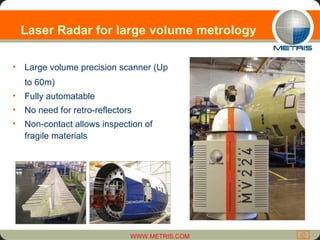

Metris is a leading provider of metrology solutions, offering both traditional and digital inspection technologies. It has a global presence with offices worldwide and over 500 employees. Metris aims to improve customers' processes through innovative metrology solutions and offers the most complete portfolio of products, including coordinate measuring machines, laser scanning systems, X-ray and CT, and solutions for metrology-assisted production.