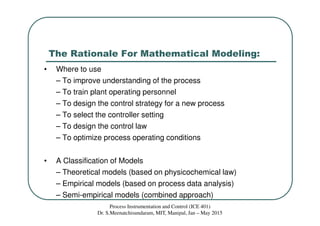

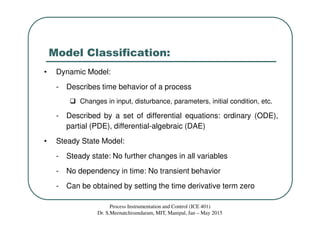

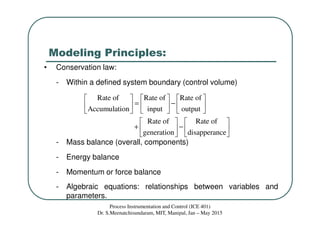

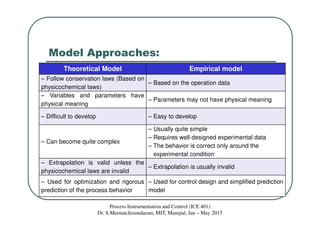

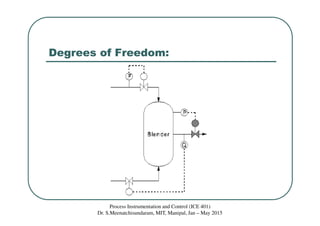

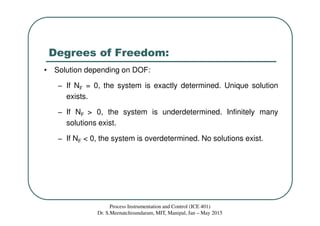

This document discusses mathematical modeling of processes. It describes the rationale for modeling, including improving process understanding, training personnel, and designing control strategies. Models can be theoretical, empirical, or semi-empirical. Dynamic models describe time behavior using differential equations, while steady state models have no time dependency. Modeling principles include conservation laws of mass, energy, and momentum. Theoretical models follow physicochemical laws, while empirical models are based on process data. Degrees of freedom analysis determines the number of variables that can be manipulated in a process.