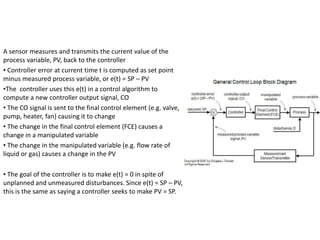

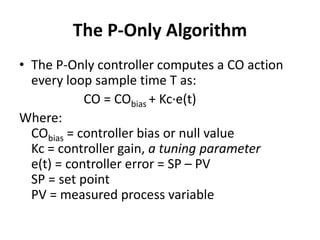

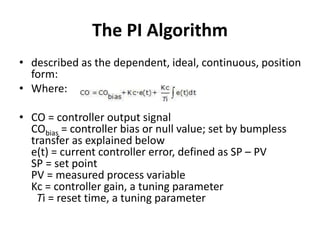

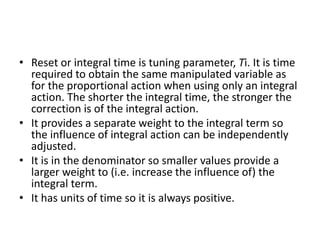

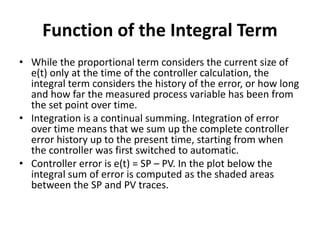

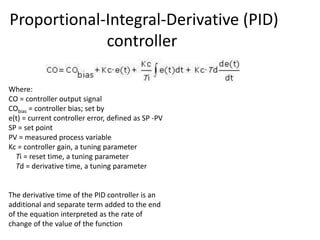

The document discusses various control mechanisms in chemical engineering, particularly focusing on proportional (P), proportional-integral (PI), and proportional-integral-derivative (PID) controllers. It explains how these controllers utilize error calculations between the set point and the process variable to adjust output signals for maintaining process stability. The interactions between their tuning parameters are highlighted, emphasizing the importance of balancing response dynamics to achieve optimal control performance.