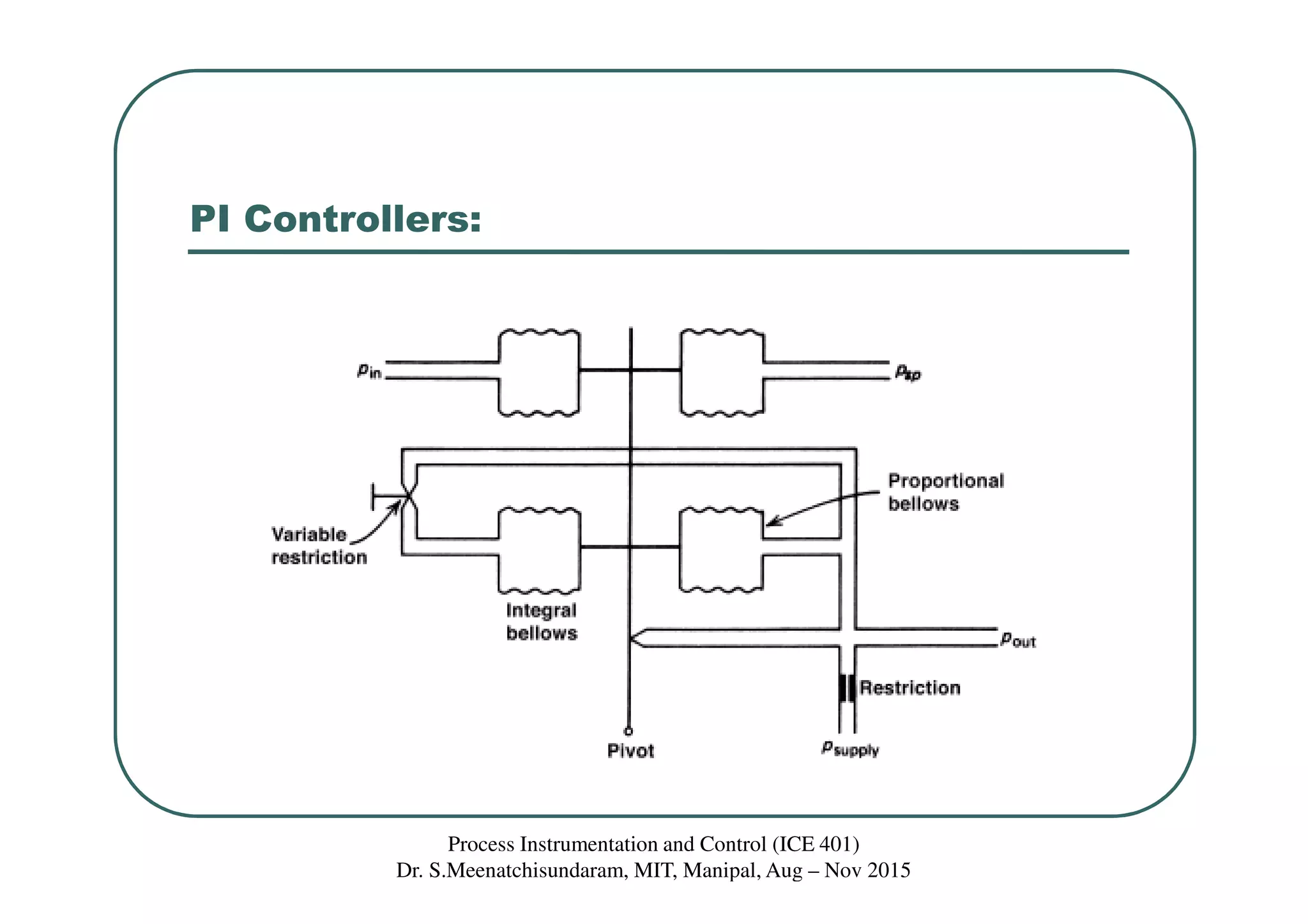

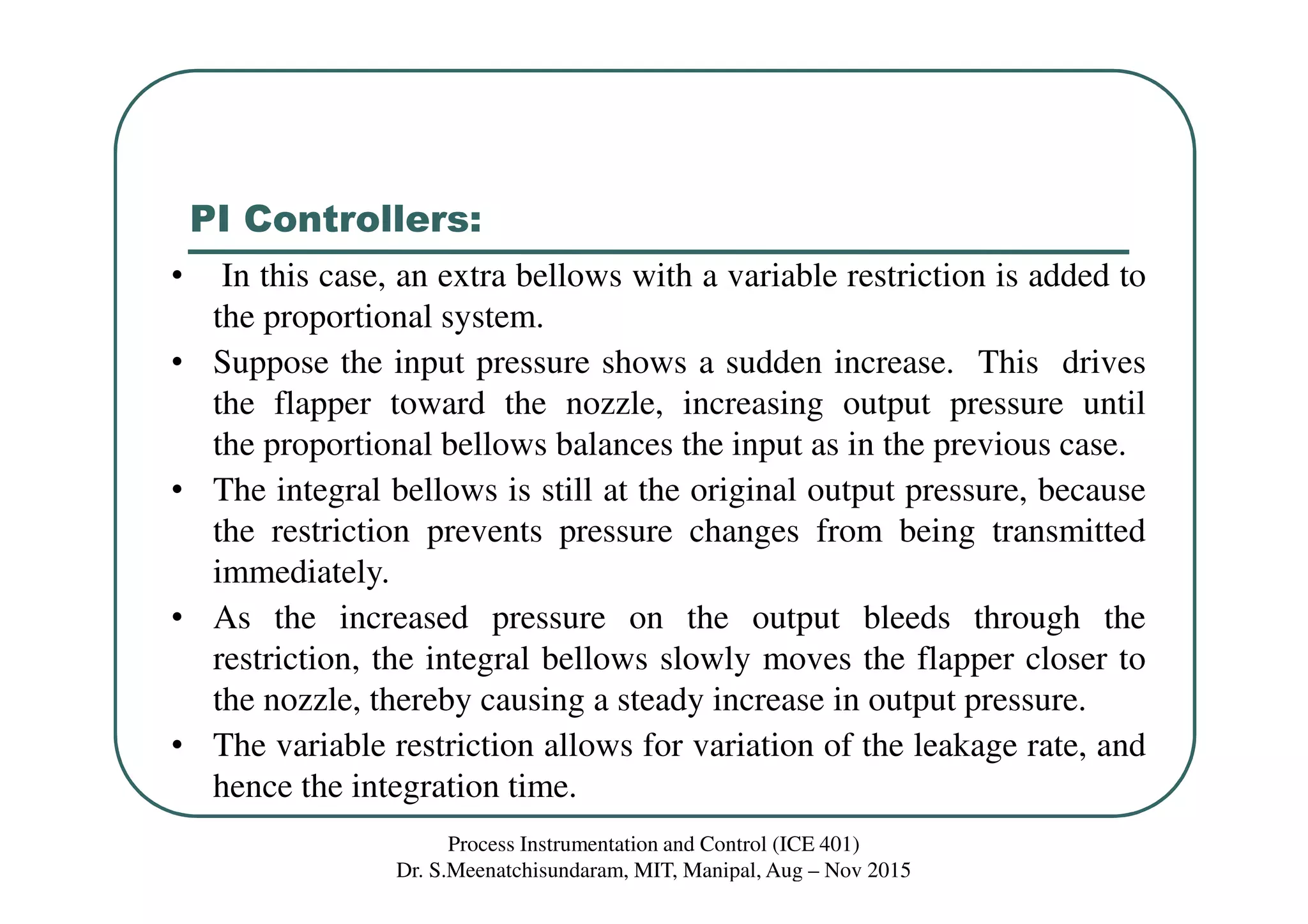

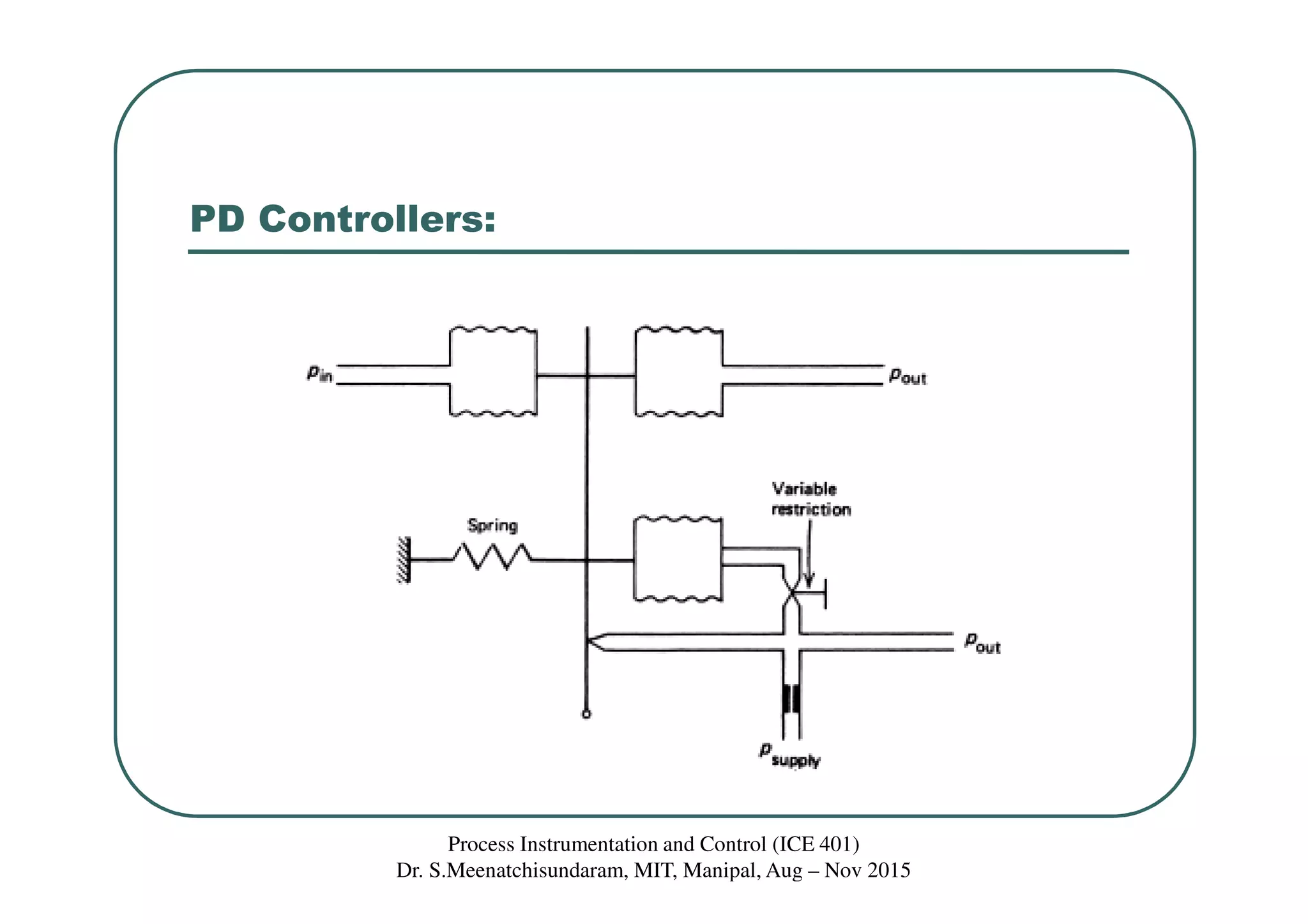

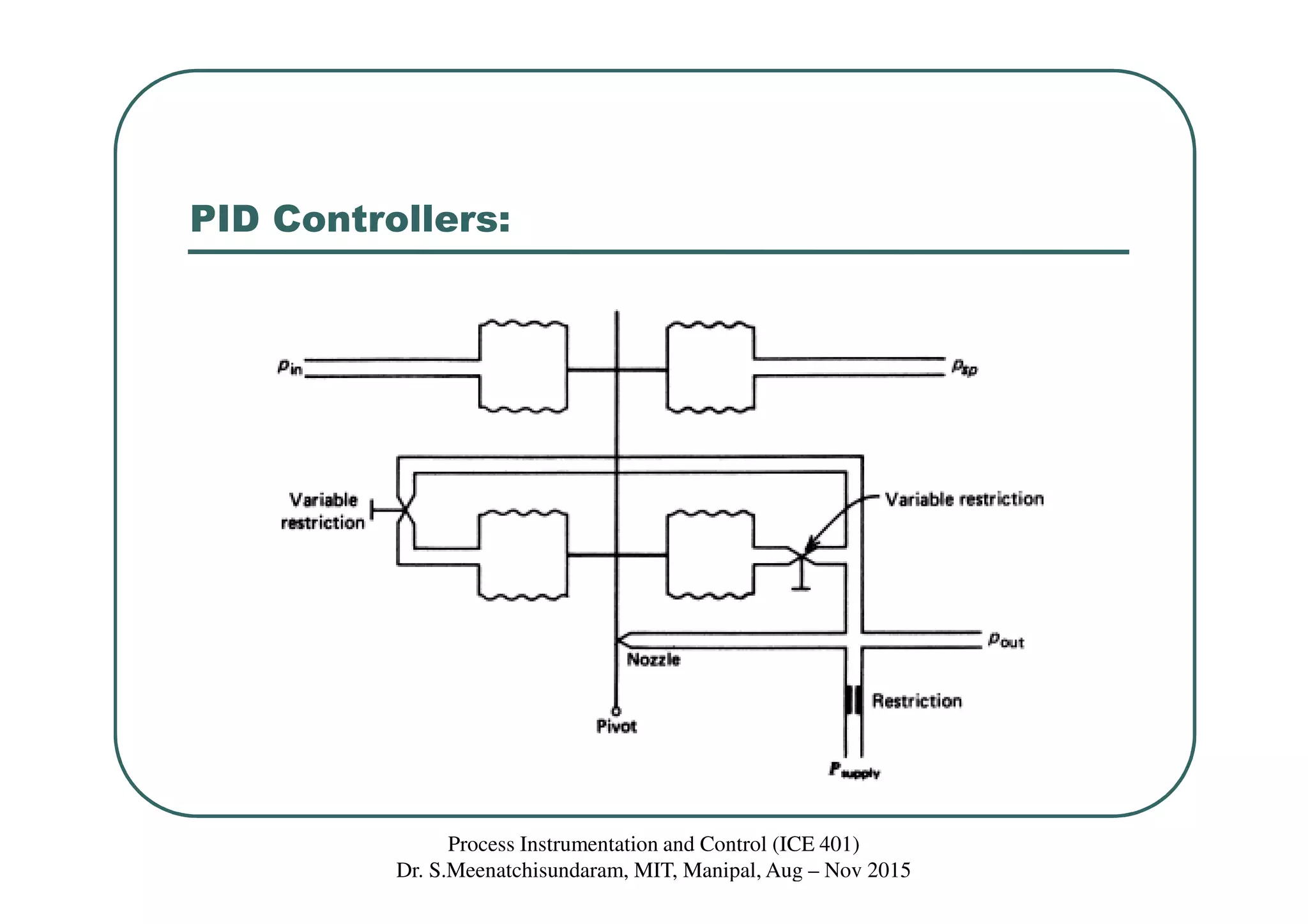

This document describes different types of pneumatic controllers - PI, PD, and PID. It explains how each type works using bellows and restrictions to achieve proportional, integral and derivative control. PI controllers use an extra bellows and restriction to provide integral action that increases output pressure over time in response to input increases. PD controllers use a restriction on the balance bellows to provide fast output response and then decrease it based on the balanced bellows. PID controllers combine all three modes into one device that can be configured to operate as any of the individual controller types through restriction settings.