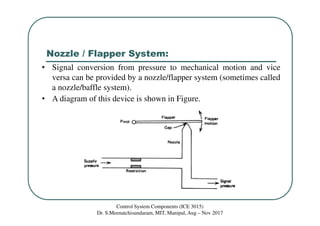

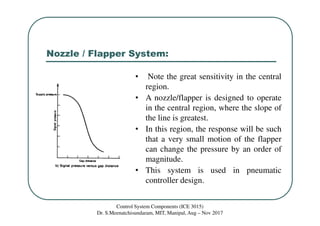

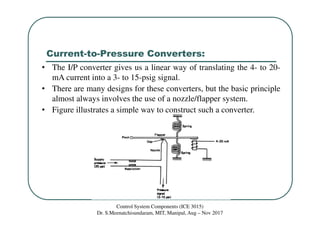

This document discusses the nozzle/flapper system and how it can be used for signal conversion between pressure and mechanical motion. It describes how a regulated air supply passes through a nozzle, and the pressure of the signal can be varied based on the distance between the nozzle and flapper. When the flapper is closed, signal pressure rises to the supply pressure, and when open, pressure drops as air leaks through. It notes this system is sensitive in the central region and used in pneumatic controllers. It also explains that current-to-pressure converters use a nozzle/flapper system to linearly translate a 4-20 mA current into a 3-15 psig signal.