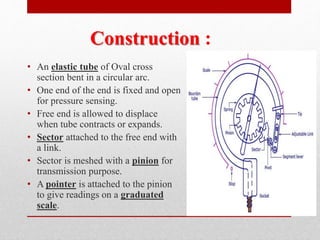

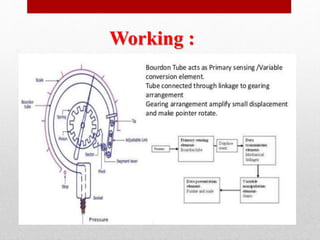

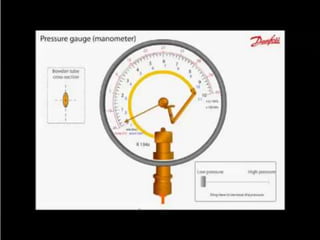

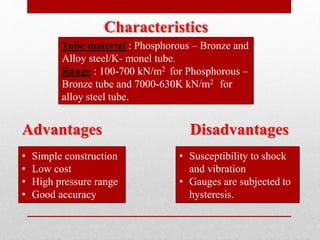

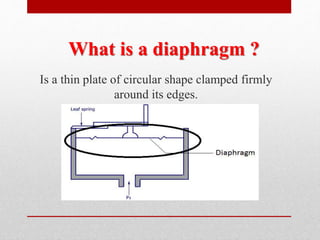

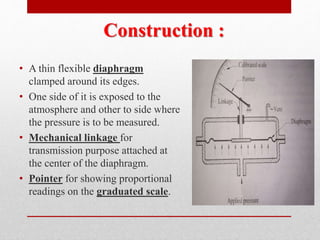

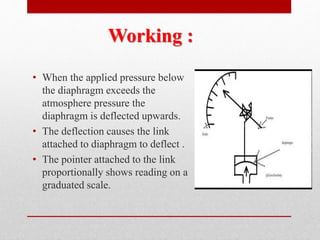

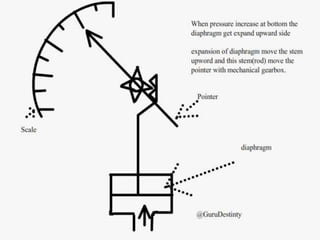

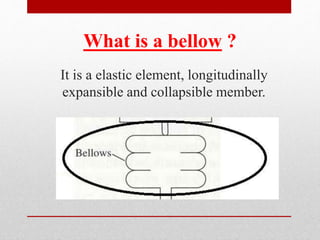

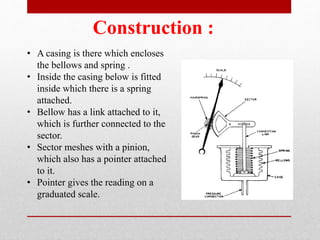

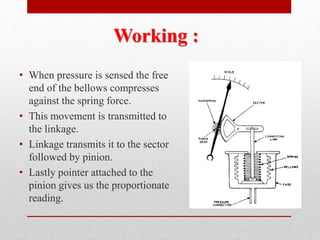

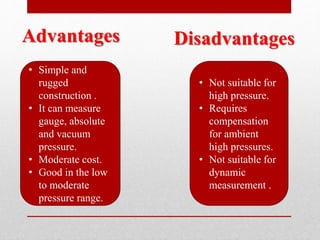

This document summarizes four common types of elastic pressure measurement instruments: bourdon tube pressure gauges, diaphragm pressure gauges, bellows pressure gauges, and capsules. It describes the construction, working principle, characteristics, advantages, and disadvantages of each type. Bourdon tube pressure gauges use an oval cross-section tube that contracts or expands to transmit pressure readings. Diaphragm pressure gauges use a thin circular plate that deflects upwards under pressure. Bellows pressure gauges use an expandable and collapsible bellows element attached to a linkage.