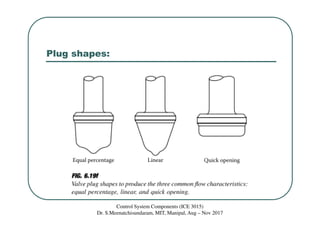

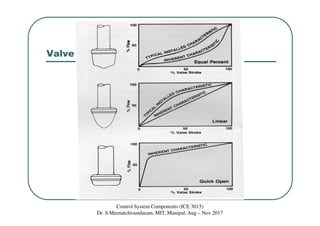

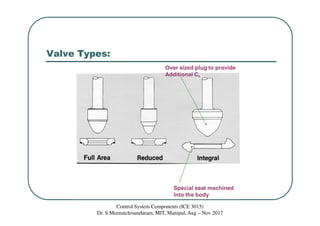

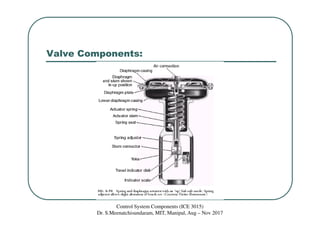

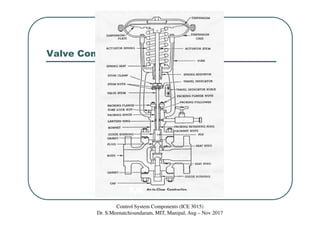

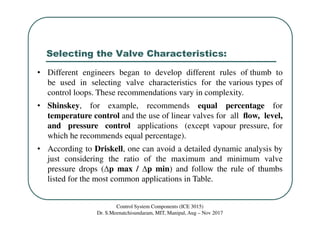

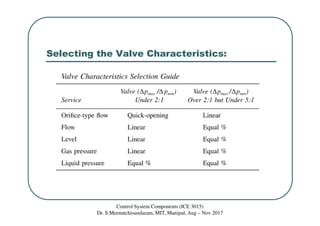

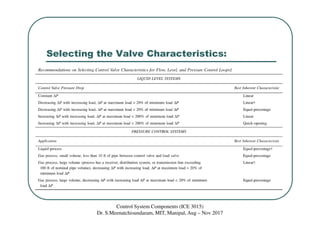

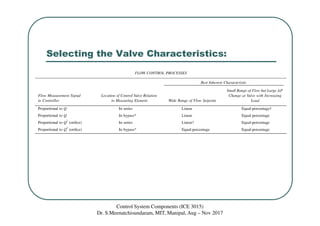

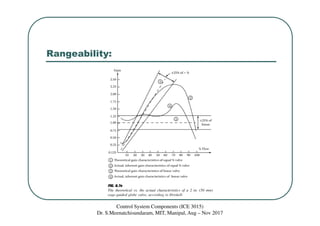

The document discusses valve selection and characteristics. It describes different valve types including plug and globe valves. It discusses factors to consider when selecting a valve such as the application, the ratio of maximum to minimum pressure drops, and common rule of thumbs for applications. The document also defines rangeability as the ratio of maximum to minimum controllable flow through a valve and provides typical rangeability ratios for different valve types.