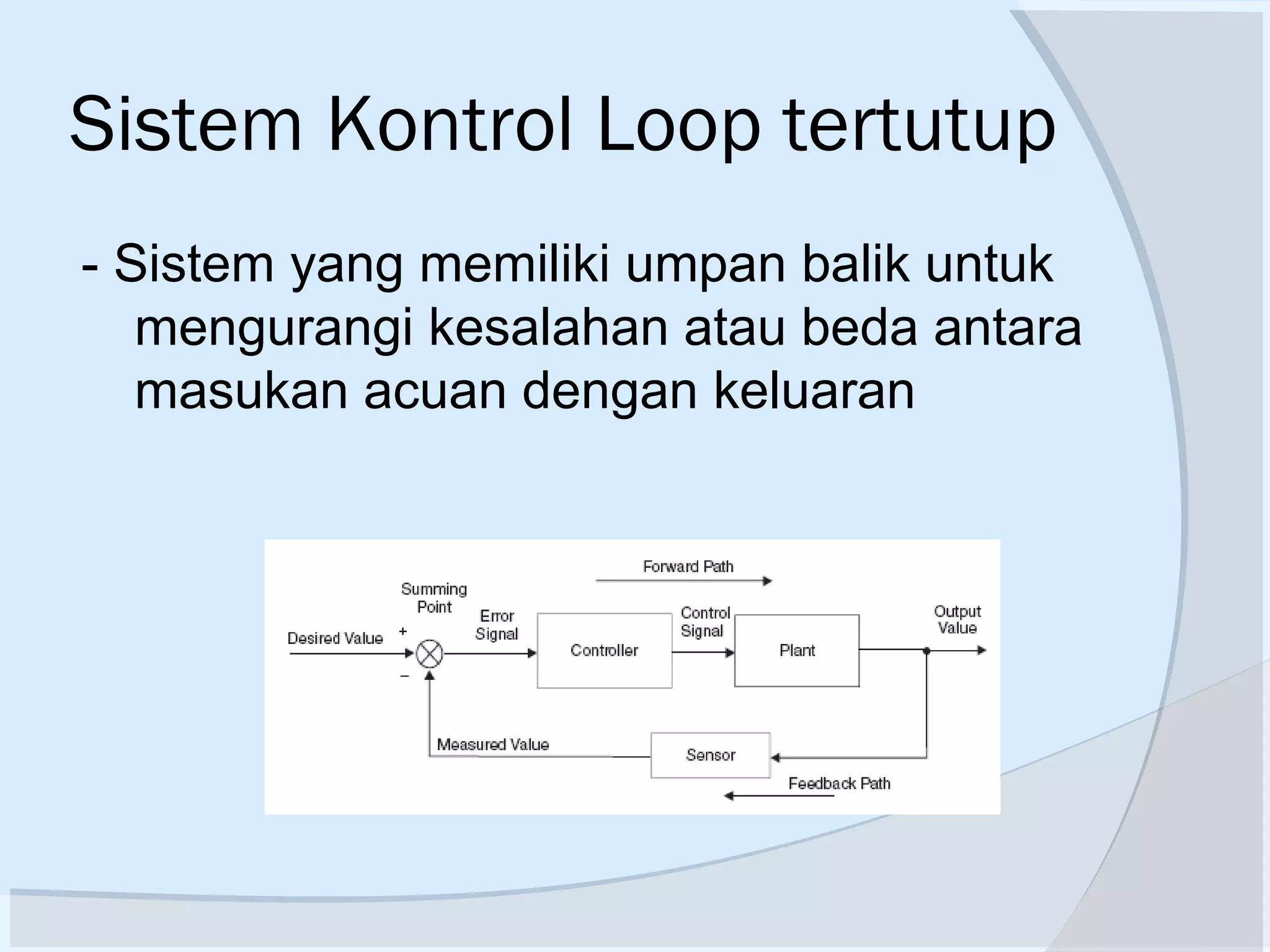

This document discusses control systems. It begins by introducing basic control system concepts like open and closed loop systems. Open loop systems do not use feedback, while closed loop systems incorporate feedback to reduce errors. It then provides examples of control systems from various applications like temperature control, robotics, and vehicle steering. The document concludes by outlining the design process for control systems, which involves understanding the system, developing mathematical models, specifying performance goals, selecting sensors and actuators, designing and simulating controllers, and testing on the real system.