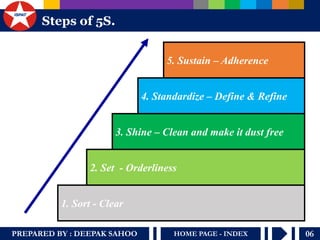

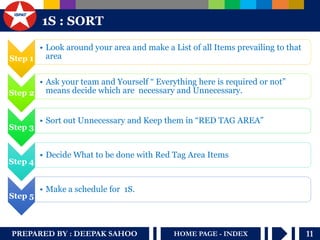

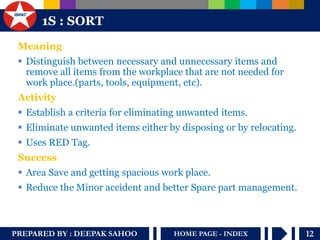

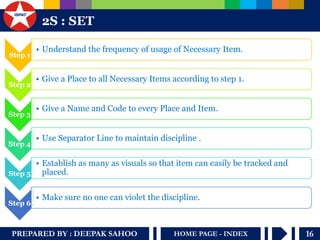

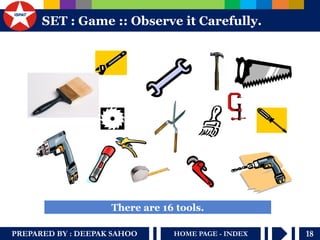

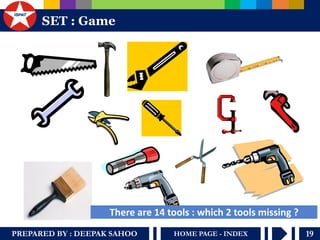

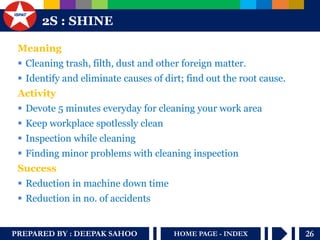

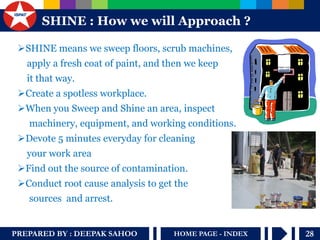

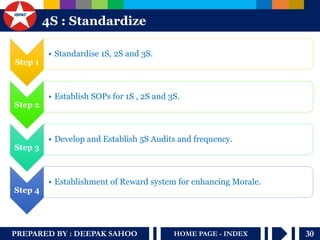

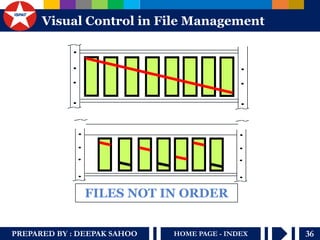

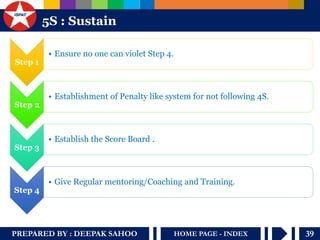

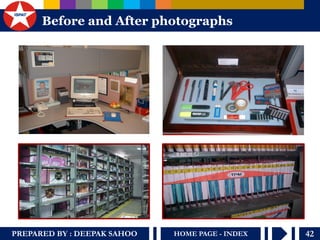

This document presents an overview and training program about 5S (Seiri, Seiton, Seiso, Seiketsu, Shitsuke), a methodology for organizing the workplace. It discusses the benefits of 5S including safety, efficiency, quality and eliminating breakdowns. It provides details on the 5 steps - Sort, Set in Order, Shine, Standardize, and Sustain. Examples and exercises are given to demonstrate how to implement each step. The goal is to create a clean, safe and efficient workplace through establishing standards and sustaining 5S practices over time.