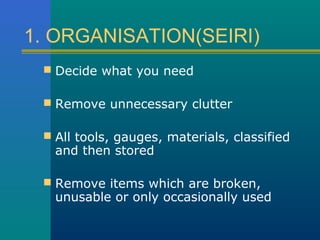

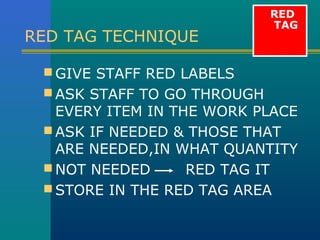

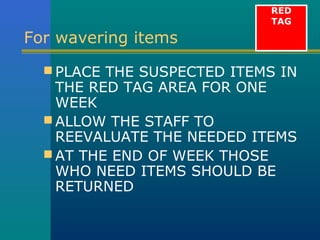

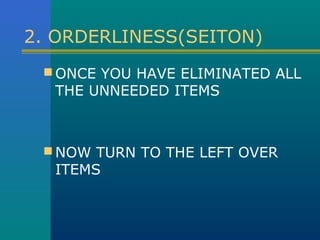

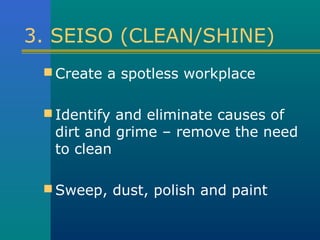

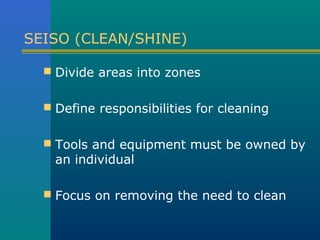

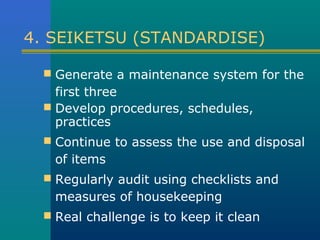

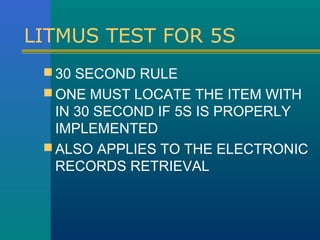

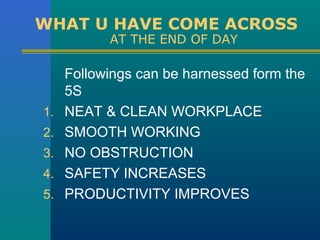

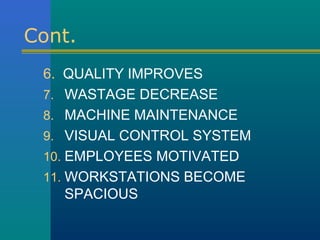

The 5S methodology is a workplace organization technique developed in Japan that involves 5 steps: sorting, setting in order, shining, standardizing, and sustaining. When implemented properly through employee involvement, 5S results in a clean, orderly, and safe work environment that improves productivity, quality, and efficiency through reduced waste of time, money, materials, and effort. It is considered the foundation for continuous improvement programs and other quality control tools.