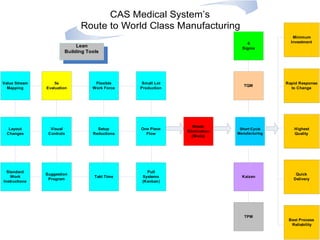

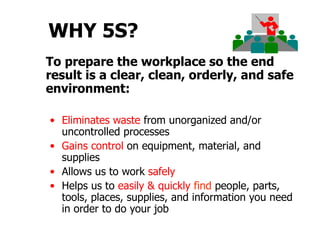

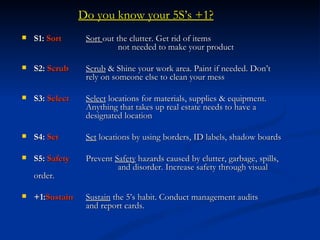

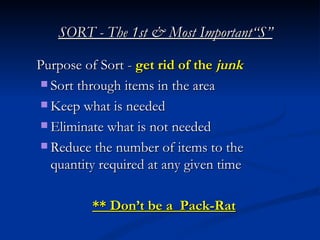

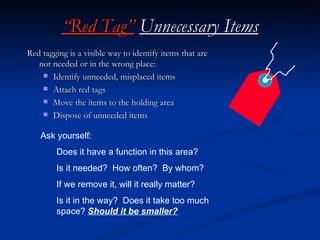

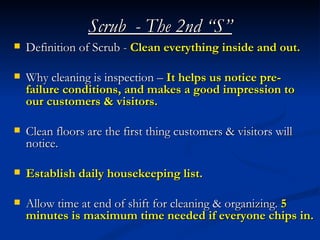

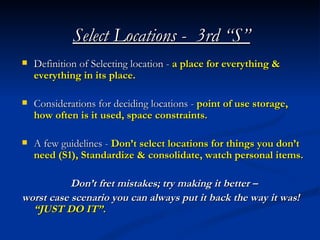

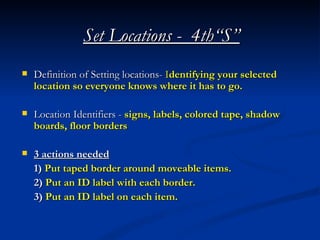

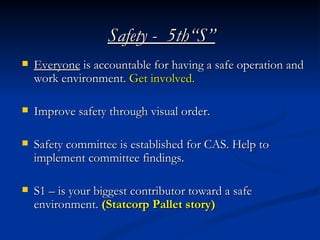

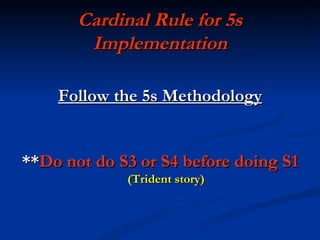

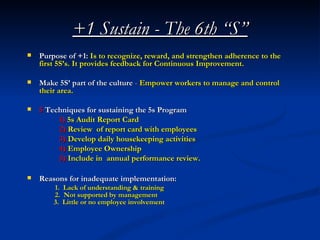

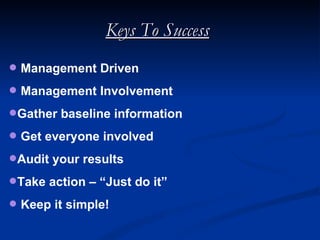

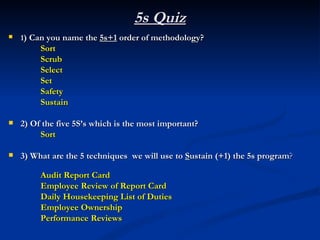

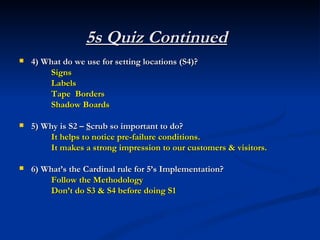

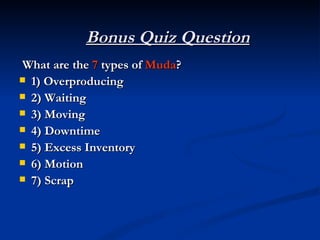

The document discusses Lean Manufacturing and 5S training. It defines Lean Manufacturing as eliminating waste to improve value for customers. 5S is an organizational method for workplace tidiness and efficiency. The 5S include Sort, Set in Order, Shine, Standardize, and Sustain. Implementing 5S through visual controls and labels can help eliminate waste and improve safety. Sustaining 5S requires ongoing audits, employee involvement, and management support.