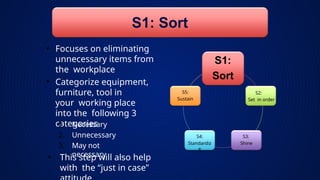

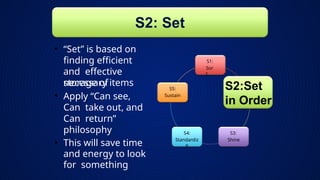

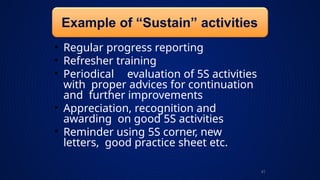

The 5S system is a methodology for organizing workspaces to enhance efficiency, safety, and cleanliness, originating in Japan in the 1980s through the Toyota Production System. It comprises five steps: Sort, Set in order, Shine, Standardize, and Sustain, aimed at eliminating waste, improving productivity, and fostering employee pride. Effective implementation of 5S leads to reduced costs, improved satisfaction, and a more streamlined workflow.