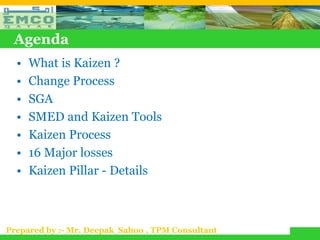

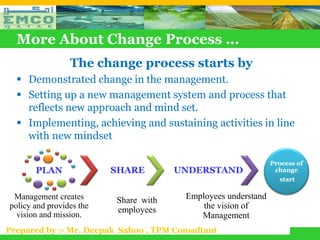

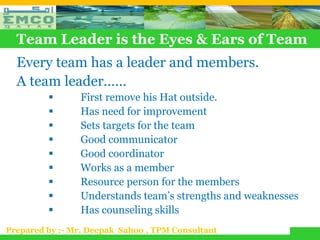

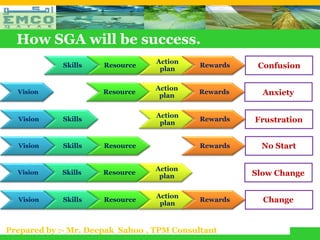

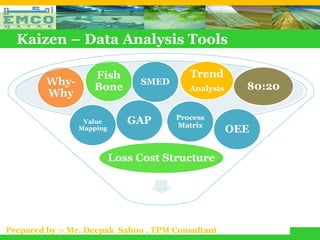

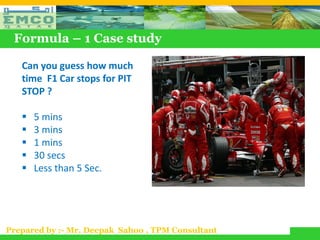

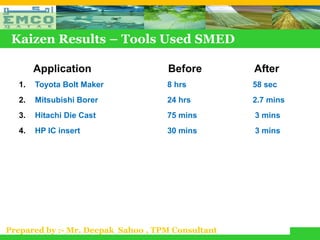

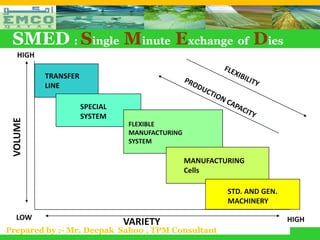

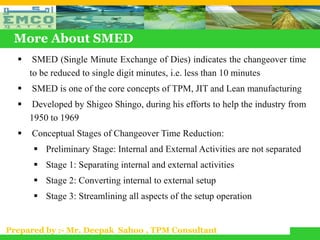

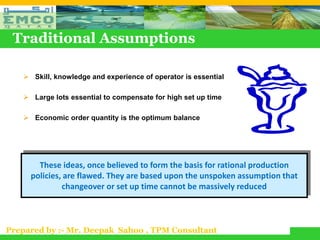

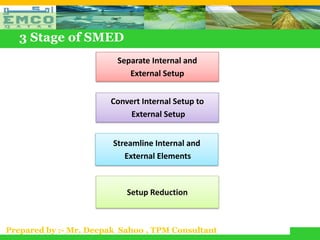

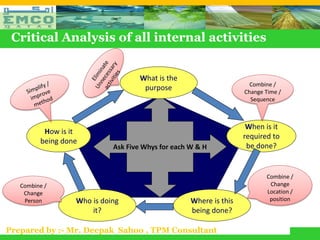

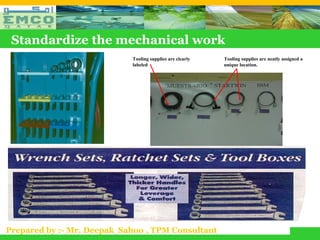

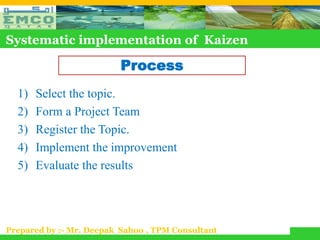

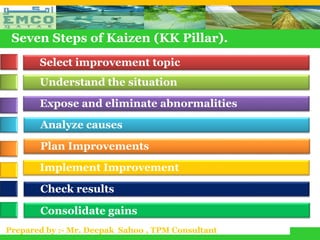

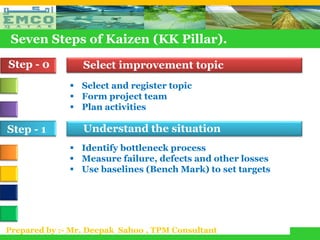

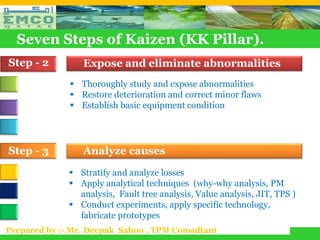

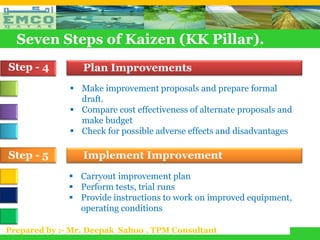

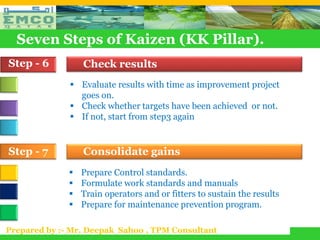

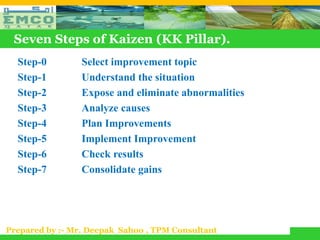

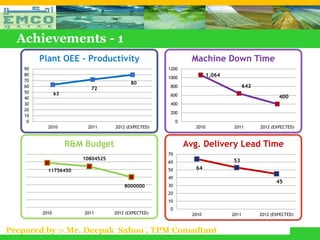

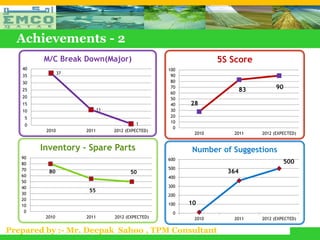

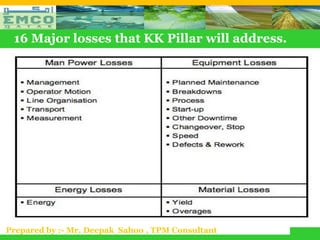

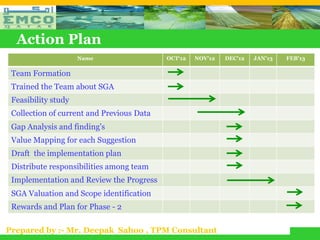

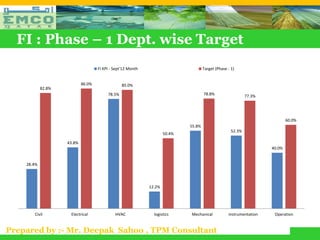

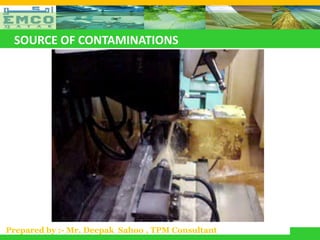

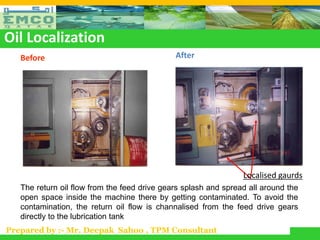

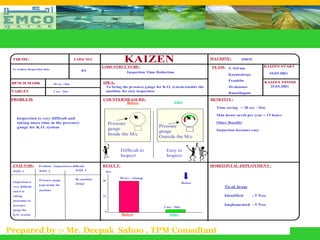

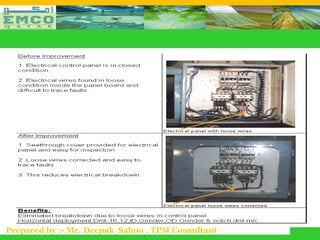

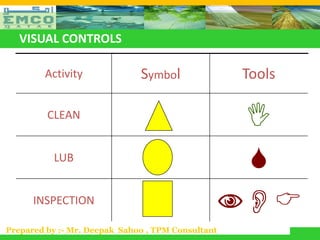

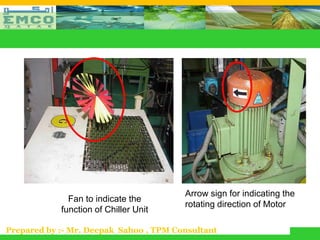

The document outlines the principles and implementation of Kaizen practices aimed at improving productivity, quality, and worker morale while reducing costs and response times in the workplace. It discusses essential concepts such as change processes, team dynamics, and Kaizen tools including SMED and 5S, as well as a structured approach for systematic implementation. The goal is to maximize overall plant effectiveness by eliminating losses through small group activities and continuous improvement methods.