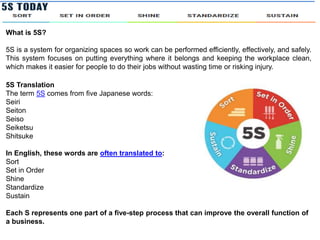

5S is a systematic approach for organizing workspaces to enhance efficiency, safety, and effectiveness by ensuring everything is sorted, set in order, cleaned, standardized, and sustained. Originating from the Toyota Production System, 5S aims to eliminate waste and improve operational performance, leading to benefits such as reduced costs and higher employee satisfaction. The methodology can be applied across various industries, not just manufacturing, and emphasizes the importance of visual management to facilitate organization.