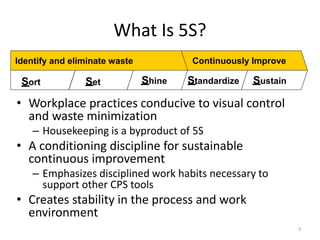

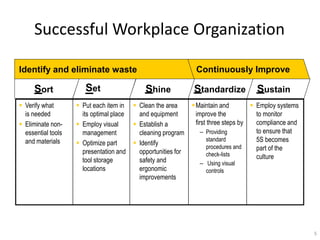

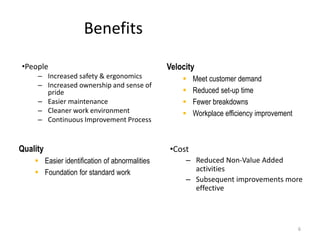

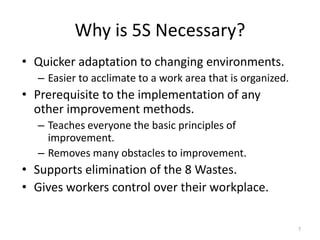

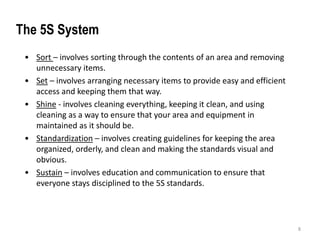

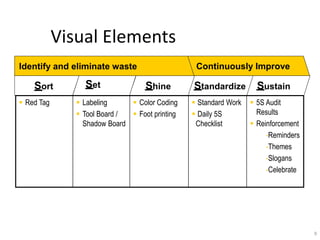

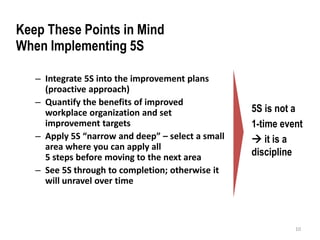

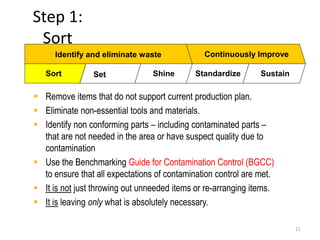

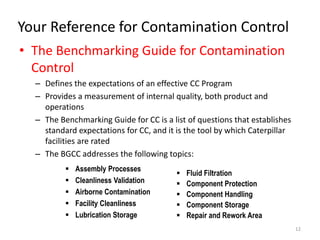

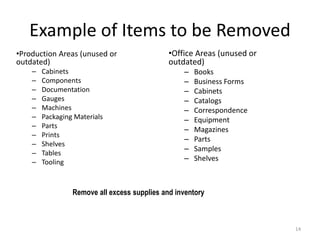

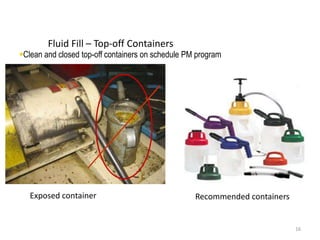

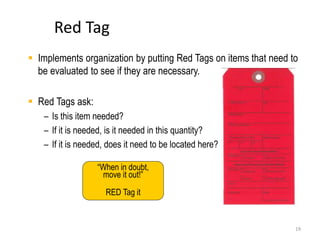

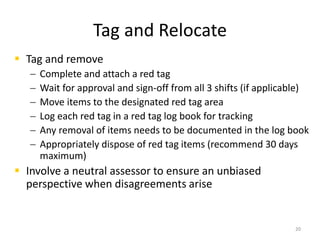

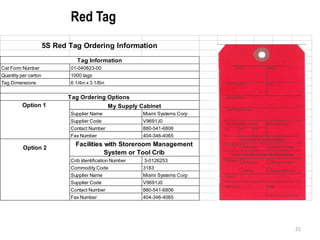

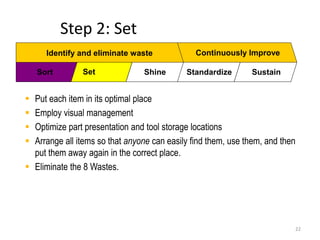

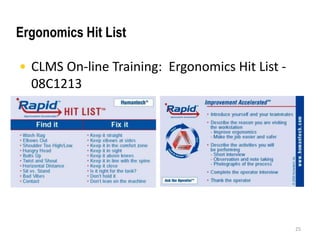

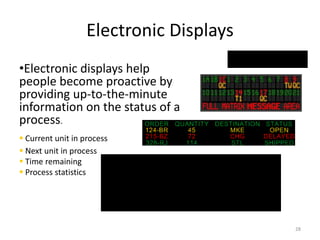

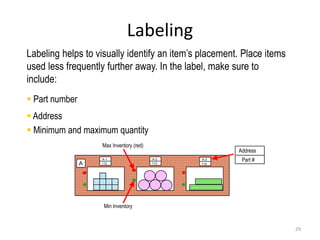

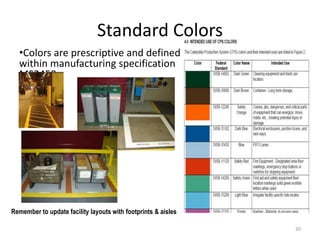

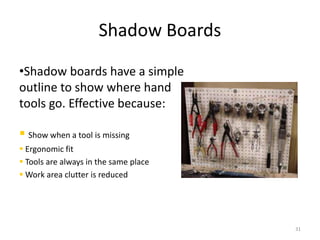

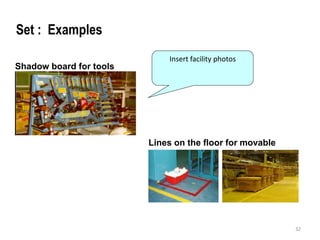

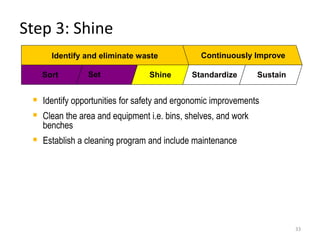

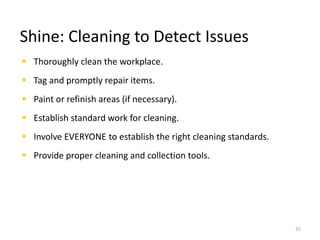

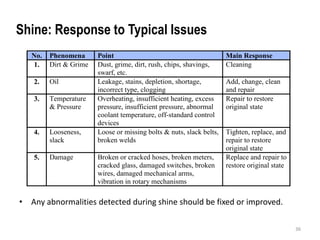

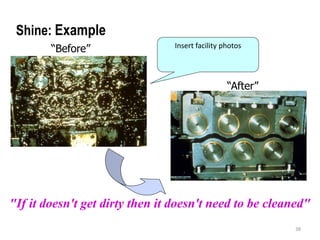

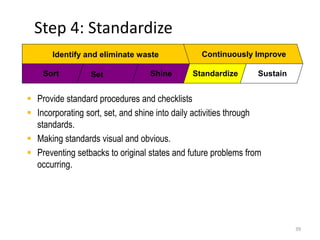

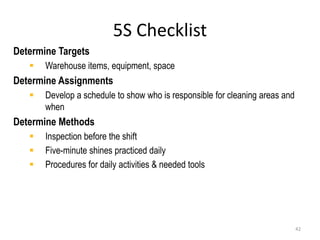

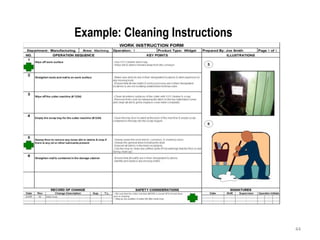

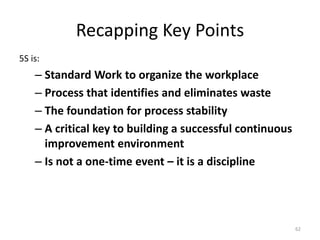

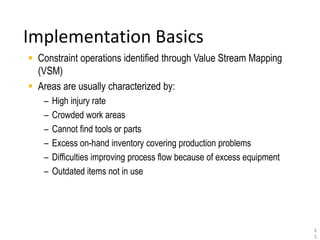

This document provides an overview of 5S training. The 5S system involves five steps - Sort, Set in Order, Shine, Standardize, and Sustain - for organizing and cleaning a workplace. It discusses the benefits of 5S including improved safety, quality and efficiency. Key aspects of implementing each 5S step are described such as identifying unnecessary items in Sort, optimizing storage locations in Set in Order, establishing cleaning standards in Shine, and visual management techniques for Standardize. Sustaining 5S requires ongoing communication to ensure standards are followed. The overview explains how 5S creates a more productive work environment through visual controls and waste elimination.