This document provides guidance on implementing the 5S methodology in three parts:

Part 1 introduces the 5S methodology and its benefits, which include improved quality, productivity, safety, and equipment reliability. The 5S methodology consists of five steps: Sort, Set In Order, Shine, Standardize, and Sustain.

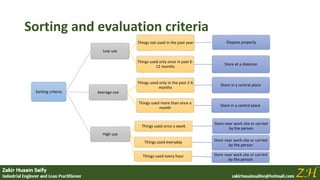

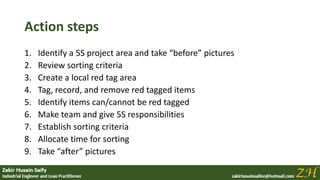

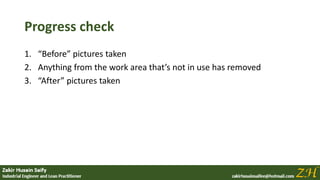

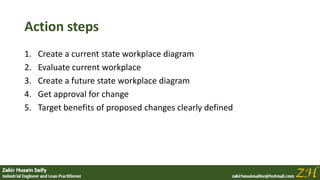

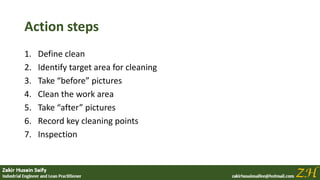

Part 2 describes how to implement each of the 5S steps, including setting goals, appointing champions, sorting through items to eliminate unnecessary ones, reorganizing the workspace, defining cleaning standards, and documenting new standards.

Part 3 discusses sustaining 5S efforts through monitoring, expanding to other areas, continuous improvement, and recognizing strong efforts. The overall goal is to create a clean,