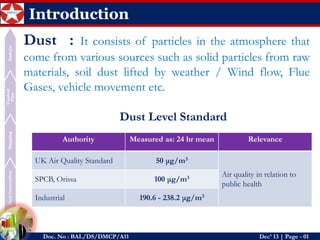

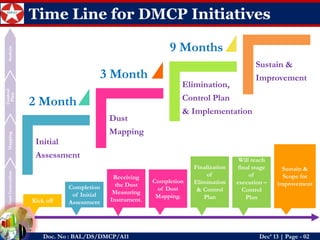

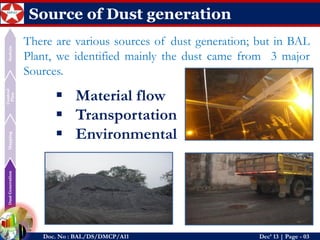

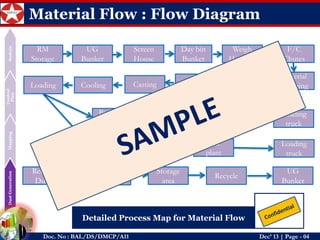

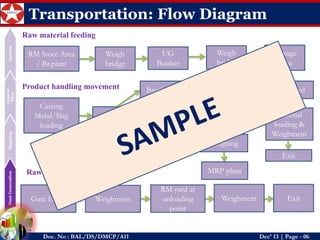

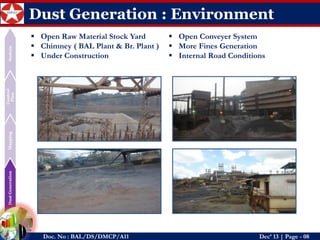

This document outlines Balasore Alloys Ltd.'s Dust Generation Mapping and Control Plan initiative to achieve a dust-free environment at their plant. It includes an introduction to dust and standards, timelines for the initiative, sources of dust generation from material flow, transportation and environmental factors, the importance of dust mapping to measure and control dust, proposed equipment for dust mapping, the dust mapping process, and potential elimination and control plans for material flow, transportation and environmental sources of dust. Control plans provide detailed suggestions and considerations for engineering teams to reduce dust from various areas and processes.

![Dust Generation

Mapping

Control Plan

Sustain

Doc. No : BAL/DS/DMCP/A11Dec’ 13 | Page -i

Objective

Achieving

Dust Free Environment

in Plant Premises

through

Dust Mapping &Control Plan

[DMCP] Initiative.](https://image.slidesharecdn.com/dustmappingandcontrolplanbydeepaksahoo-141109145419-conversion-gate01/85/Dust-Mapping-and-Control-Plan-DMCP-by_Deepak-Kumar-Sahoo-2-320.jpg)

![Dust Generation

Mapping

Control Plan

Sustain

Doc. No : BAL/DS/DMCP/A11Dec’ 13 | Page –ii

Table of Contents

S/N

Contents

Pg. No.

1

Introduction

-: 01:-

2

DustGeneration [Source]

-: 03 :-

2.1

1. Material Flow

-: 04:-

2.2

2.Transportation

-: 06:-

2.3

3.Environment

-: 08:-

3

Dust Mapping

-: 09:-

4

Elimination & Control Plan

-: 12:-

4.1

1. Material Flow

-: 13:-

4.2

2.Transportation

-: 14:-

4.3

3.Environment

-: 15:-

5

ROI for DMCP Initiative

-: 16:-

6

Sustain

-: 17:-](https://image.slidesharecdn.com/dustmappingandcontrolplanbydeepaksahoo-141109145419-conversion-gate01/85/Dust-Mapping-and-Control-Plan-DMCP-by_Deepak-Kumar-Sahoo-3-320.jpg)

![Dust Generation

Mapping

Control Plan

Sustain

Doc. No : BAL/DS/DMCP/A11Dec’ 13 | Page -10

Dust Mapping : Measuring Device

HAZ-DUST Real-time Area Dust Monitor

P311

DT-9881

P611

$ 1763

£1.764,00

£847

£2425

SKC Inc.

PCE Instruments UK Ltd.

PCE Instruments UK Ltd.

PCE Instruments UK Ltd.

The Avg. Cost of Dust Measuring Device is costing around 2 LacsINR and the lead time Maximum 15 days. [Date of Payment to Equipment received @ BAL Plant.]](https://image.slidesharecdn.com/dustmappingandcontrolplanbydeepaksahoo-141109145419-conversion-gate01/85/Dust-Mapping-and-Control-Plan-DMCP-by_Deepak-Kumar-Sahoo-13-320.jpg)