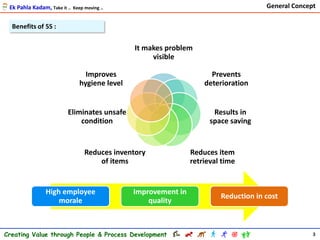

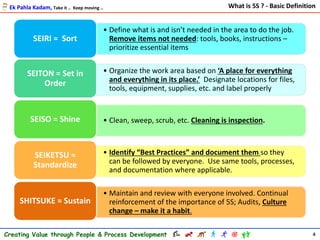

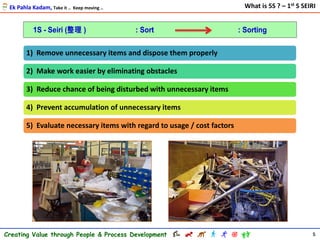

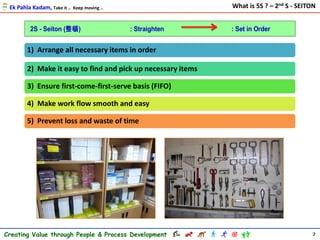

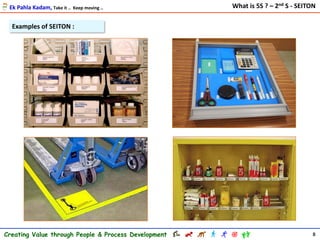

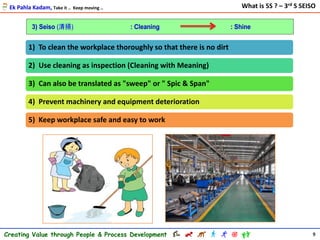

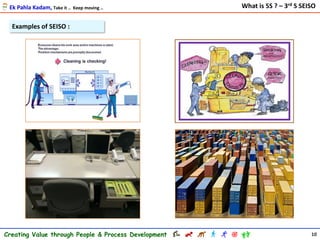

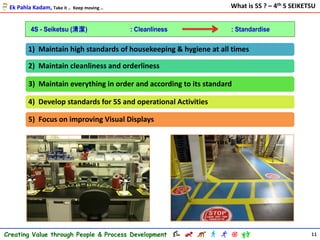

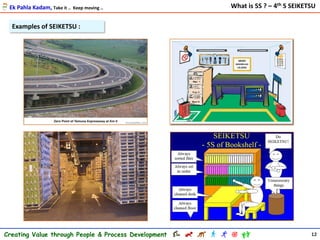

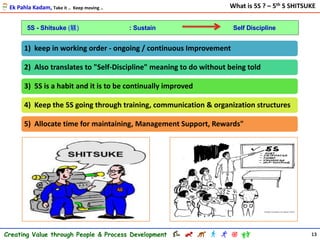

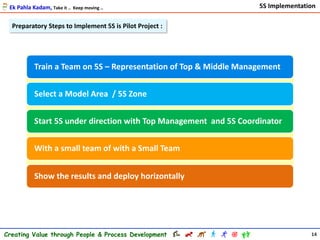

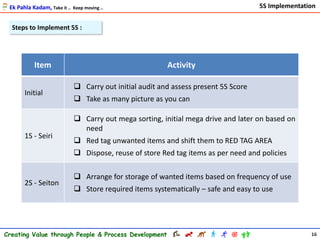

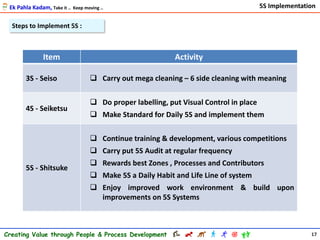

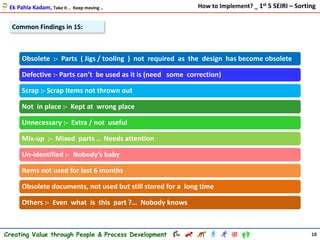

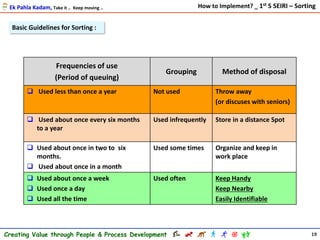

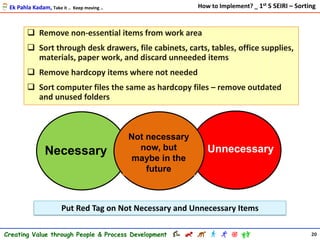

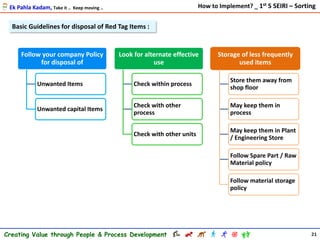

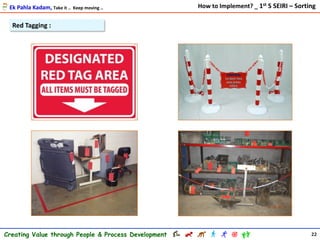

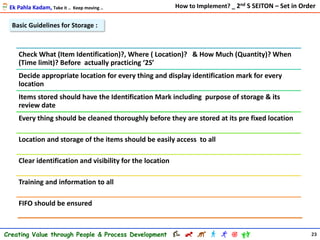

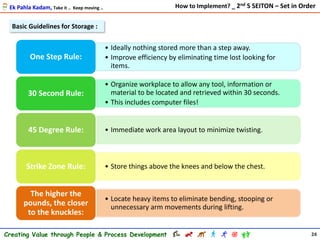

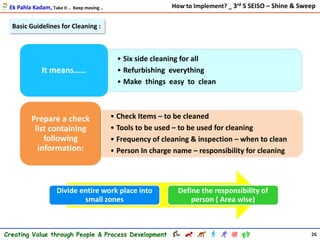

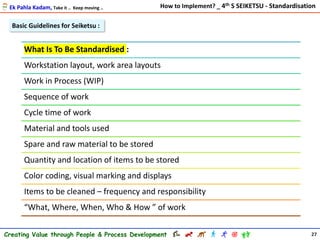

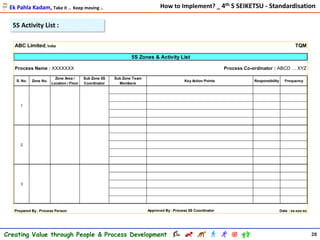

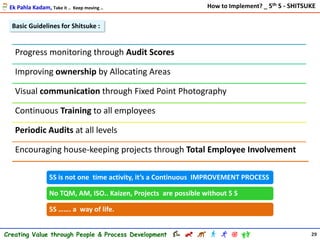

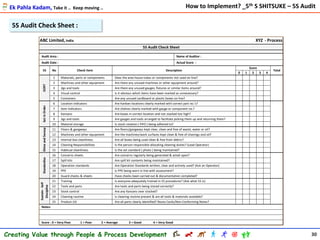

This document discusses the 5S workplace organization system. 5S involves sorting, setting in order, shining, standardizing, and sustaining. The benefits of 5S include making problems visible, preventing deterioration, saving space, reducing retrieval time, reducing inventory, eliminating unsafe conditions, and improving morale. Implementing 5S involves sorting items to remove unnecessary items, organizing the workspace, cleaning thoroughly, standardizing processes, and sustaining the system through training and audits. The first S, seiri, focuses on sorting items into necessary, unnecessary, and potentially necessary categories for proper disposal or storage.